Seed pelleting machine

A coating machine and seed technology, which is applied in the direction of seed coating/seed dressing, etc., can solve the problems of high manufacturing cost and use cost, large volume, poor mixing effect, etc., and achieve improved mixing effect and mixing effect Good, good utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

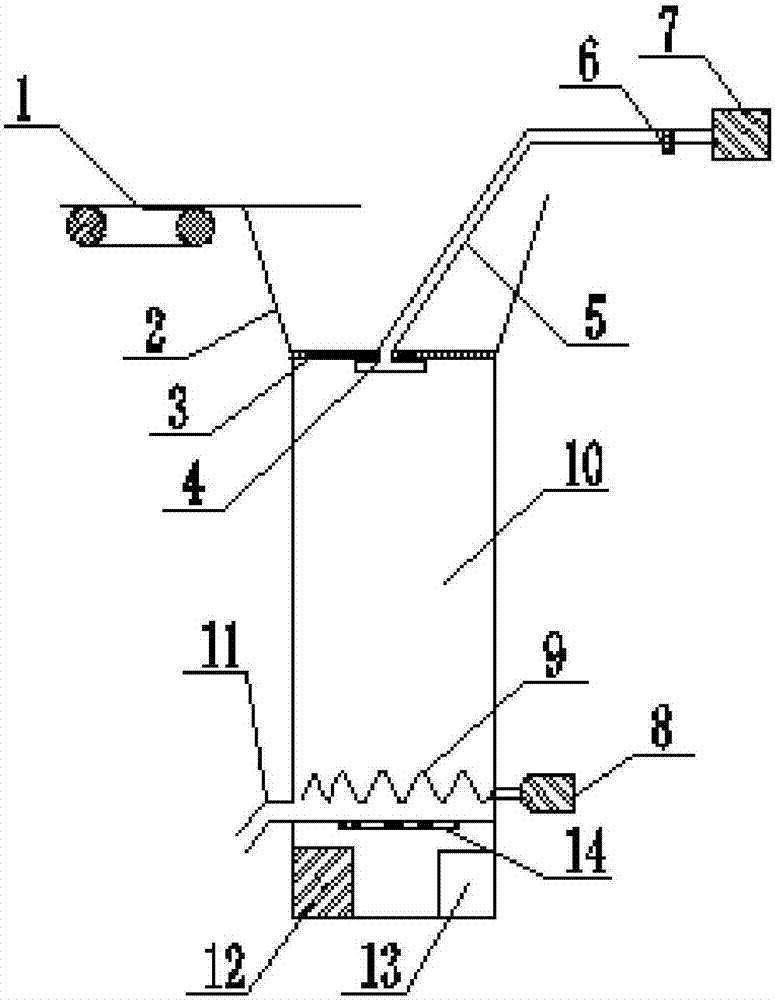

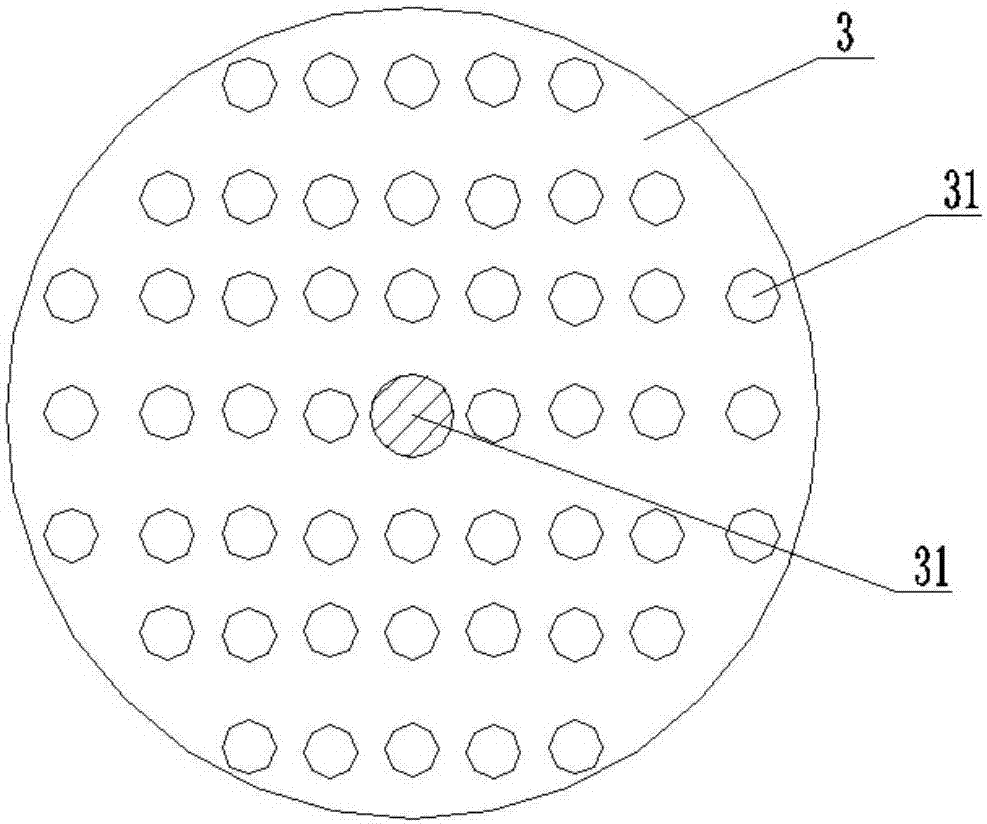

[0014] Such as figure 1 As shown, the seed coating machine of the present invention includes a feed section, a mixing section and a control section, and the feed section includes a seed conveyor belt 1, a seed inlet box 2, a seed drain plate 3, a spray nozzle 4, a drug delivery pipe 5, a medicine Liquid output pump 6, medicine supply dose box 7; The feeding part is used for the input of seed and medicine. The mixing part includes a stirring motor 8, an auger 9, a mixing box 10, and a seed outlet 11; the mixing part is used for mixing seeds and medicines, and discharging the mixed seeds. The control part includes a vibration device 12, a control device 13, and a heating device 14, which are used for vibration heating and control of seeds.

[0015] Such as figure 1 As shown, the seed transmission belt 1 of the present invention is arranged on the top of the seed inlet box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com