Disinfecting lamp assembly

A technology for disinfection lamps and components, which is applied in the direction of disinfection and irradiation, which can solve the problems of the disinfection unit not being able to rotate, and achieve the effect of improving disinfection efficiency and increasing the disinfection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

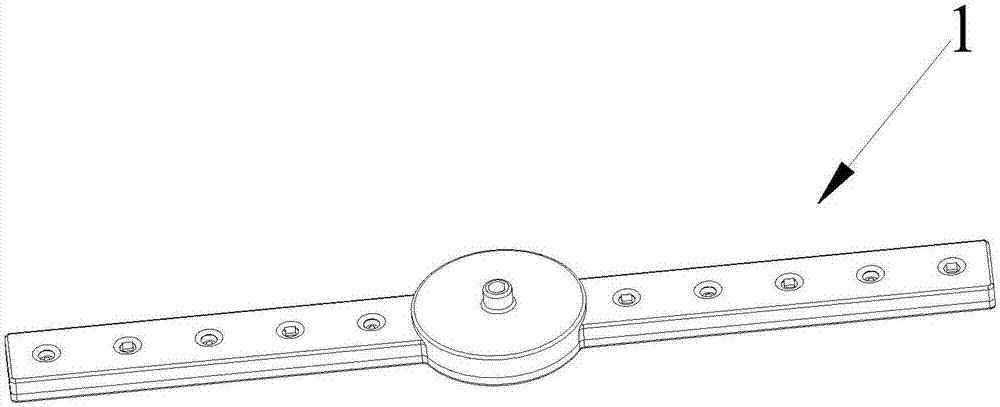

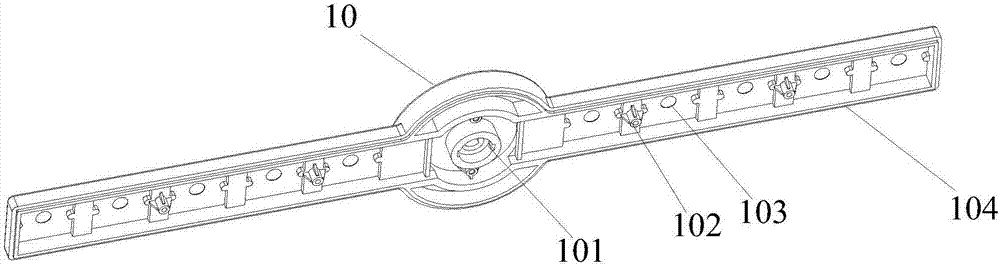

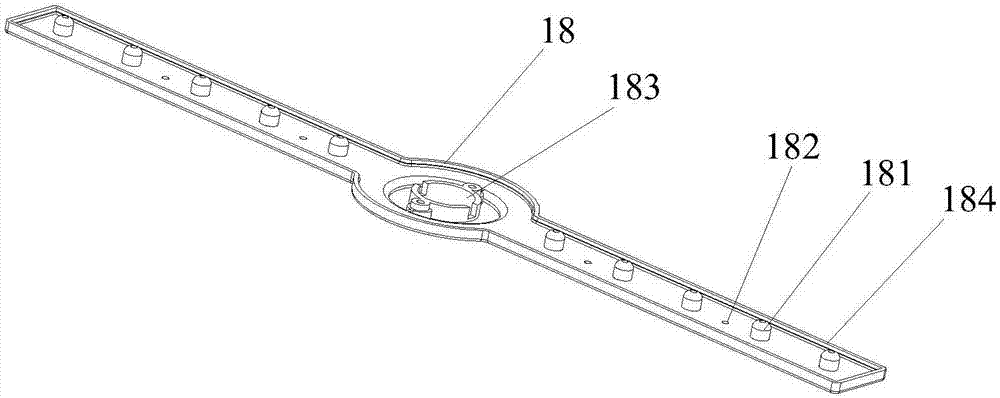

[0028] see figure 1 , The disinfection lamp assembly 1 includes a top cover 10 and a bottom cover 18 , and a UVC-LED ultraviolet lamp 12 is installed between the top cover 10 and the bottom cover 18 . see figure 2 , the top cover 10 is circular and is provided with a top cover mounting hole 101 for accommodating the output shaft 20 of the motor 2 . On the top cover 10, a top cover support plate 104 is extended, and a lamp hole 103 is provided at the top cover support plate 104, and the ultraviolet rays of the 280nm wave band that the UVC-LED ultraviolet lamp 12 sends are irradiated to the article to be sterilized by the lamp hole 103. A set of lamp holes 103 can be arranged on the support plate 104, that is, a set of UVC-LED ultraviolet lamps 12 can be installed. A plurality of buckles 102 are also provided on the support plate 104 of the top cover, and the buckles 102 cooperate with the holes 182 on the bottom cover 18 so that the top cover 10 and the bottom cover 18 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com