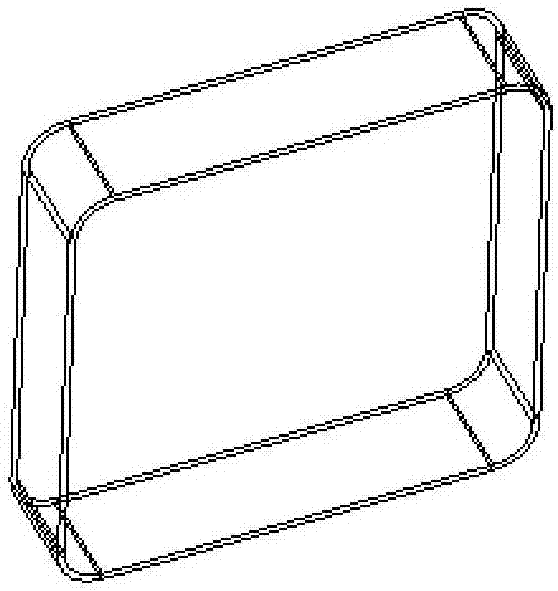

Machining method for pressureless sintered carborundum thin wall structural part

A technology of thin-walled structural parts and sintered silicon carbide, which is used in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve problems such as low processing efficiency, and achieve the effect of increasing the structural strength of workpieces and improving product processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

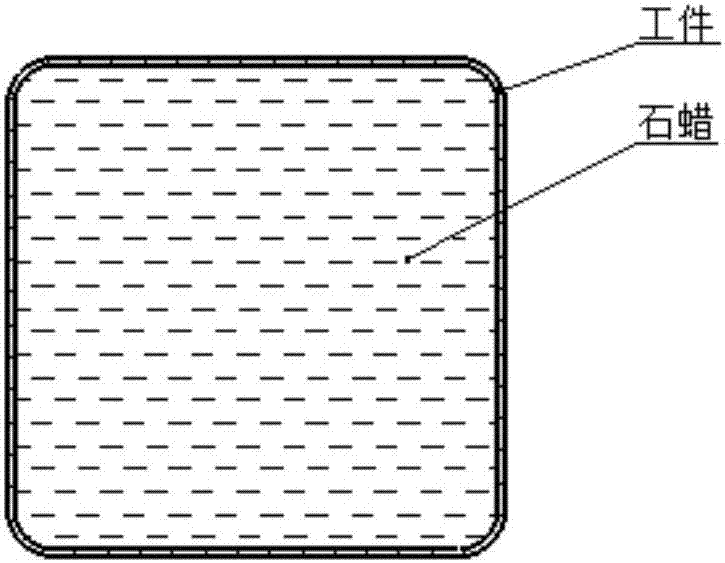

[0022] 1. First, process the upper and lower surfaces of the product, and use self-made paraffin to fill the inner hole of the product (such as figure 2 As shown), it is fixed on a surface grinder by a fixture, and the grinder processes two upper and lower planes with a feed rate of 0.02mm.

[0023] 2. Use the machining center to process the four outer sides of the workpiece, fix the workpiece filled with self-made paraffin on the worktable of the machining center through the fixture, and use Φ20-Φ40mm resin combined with diamond grinding head (diamond particle size 80-180 mesh) to The four sides of the workpiece are processed, the spindle speed is 12000rpm, and the feed rate is 0.01-0.02mm.

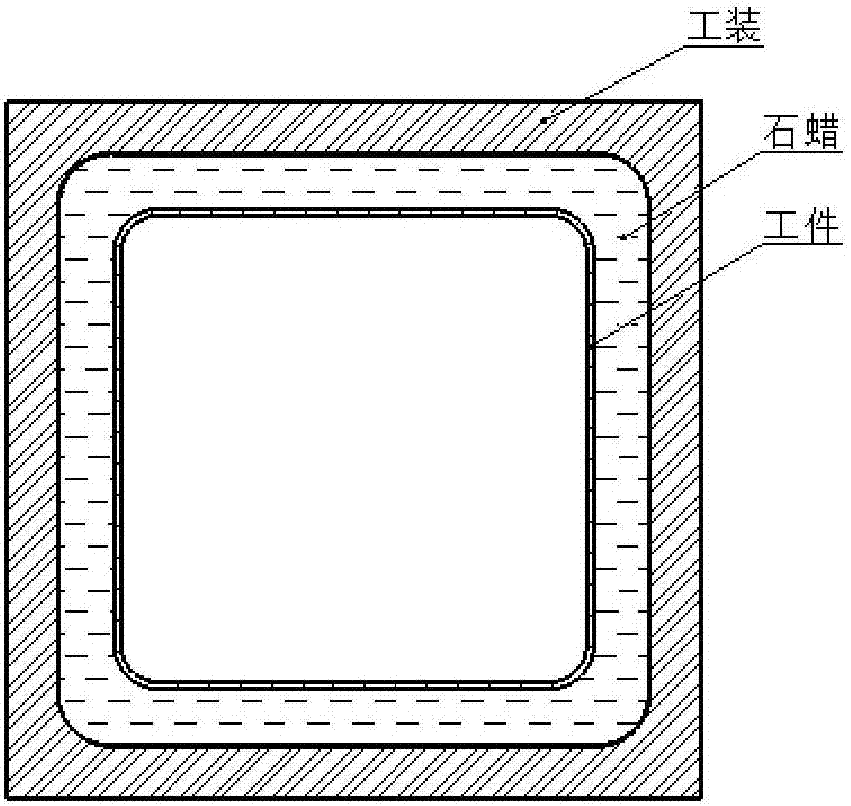

[0024] 3. Use the machining center to process the inner four sides of the workpiece, heat to remove the self-made paraffin in the inner hole of the workpiece, and place the workpiece in the middle of the metal tooling. The inner hole size of the metal tooling is 30mm larger than the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com