Intelligent hydrogel material resistance reducing system of sandwich structure

A hydrogel and sandwich technology, applied in the field of drag-reducing surface of intelligent hydrogel materials, can solve the problems of weak mechanical strength of PNIPAM hydrogel, and achieve the effect of reducing the total resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

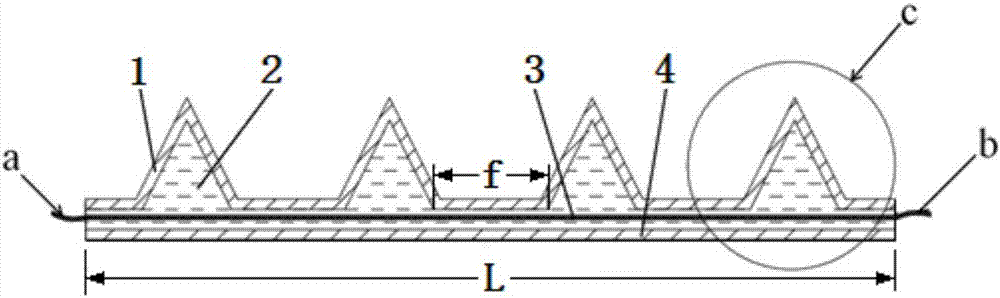

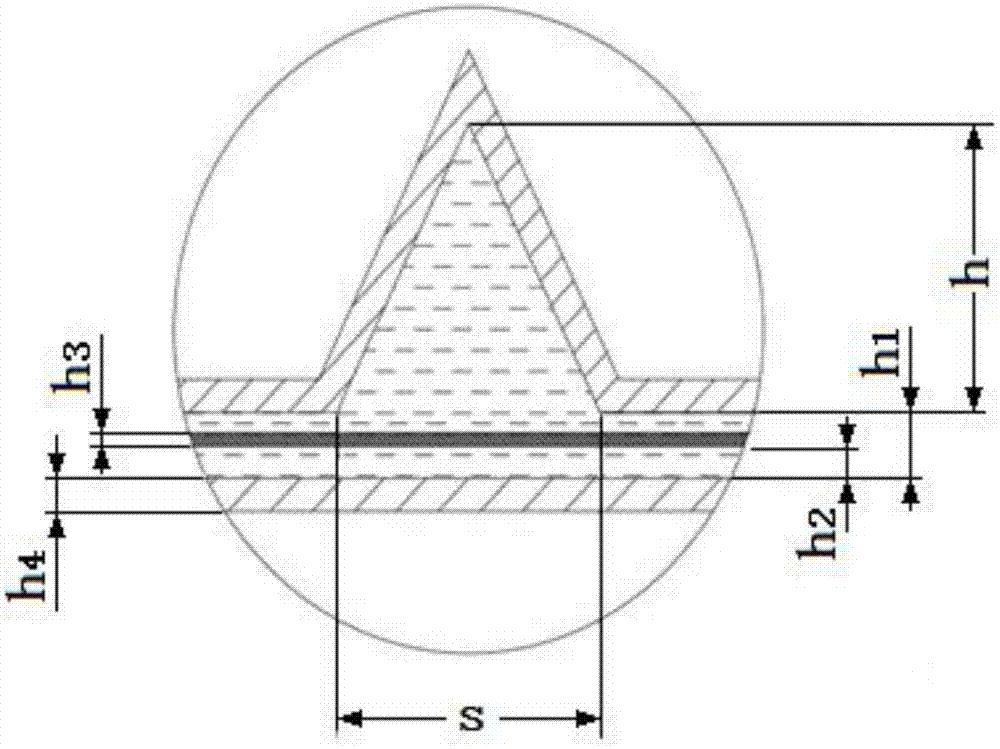

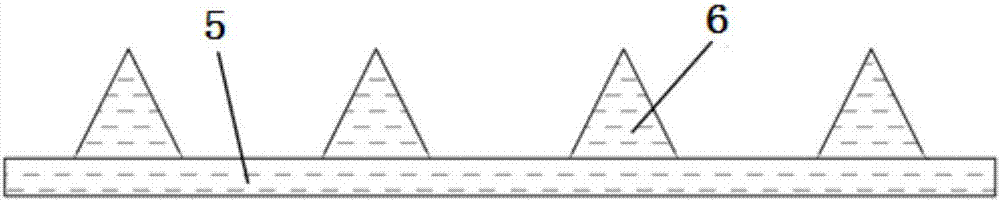

[0024] Example 1: When h + ≤25, s + When ≤30, the surface of the smart hydrogel material with a sandwich structure has drag reduction characteristics. The length L of the elongated bottom surface 5 of the PNIPAM hydrogel 2 is 2mm, and the thickness is h 1 25μm, the distance between the bottom edge of the ultrafine heating net 3 and the bottom edge of the long strip bottom surface 5 of the PNIPAM hydrogel 2 is h 2 10μm, the thickness of the ultra-fine heating net 3 h 3 It is 8μm, the mesh is 6000, the pore size is 2.5μm, the coating thickness of PAAm hydrogel I1 and PAAm hydrogel II4 on PNIPAM hydrogel 2 is h 4 It is 7μm. It is assumed that the height h of the triangular groove is 110 μm, the width s of the groove is 130 μm, and the interval f between adjacent triangles is 200 μm. When the speed is 7.72m / s, the Reynolds number is 3.30×10 7 At this time, the drag reduction rate of the smart hydrogel material with a sandwich structure is 8.07%.

Embodiment 2

[0025] Example 2: When the speed is 14.15m / s, the Reynolds number is 6.06×10 7 At this time, the ultra-fine heating net 3 is heated to 32°C through the power supply, and the size of the drag reducing surface microstructure is: the length L of the long strip bottom surface 5 of the PNIPAM hydrogel 2 is 1.5mm, and the thickness h 1 20μm, the distance between the bottom edge of the ultrafine heating net 3 and the bottom edge of the long strip bottom surface 5 of the PNIPAM hydrogel 2 is h 2 7.5μm, the thickness of the ultra-fine heating net 3 h 3 6.5μm, mesh number is 6000, pore size is 2.5μm, the coating thickness of PAAm hydrogel Ⅰ1 and PAAm hydrogel Ⅱ4 on PNIPAM hydrogel 2 is h 4 It is 6μm. The height h of the triangular groove is set to 65 μm, the width value s of the groove is 80 μm, and the interval f between adjacent triangles is 125 μm. The drag reduction rate of the smart hydrogel material with the sandwich structure is 10.05%.

Embodiment 3

[0026] Example 3: When the speed is 20.58m / s, the Reynolds number is 8.92×10 7 At this time, the ultrafine heating net 3 is heated to 34°C through the power supply, and the size of the drag reducing surface microstructure is: the length L of the elongated bottom surface 5 of the PNIPAM hydrogel 2 is 1mm, and the thickness h 1 15μm, the distance between the bottom edge of the ultrafine heating net 3 and the bottom edge of the long strip bottom surface 5 of the PNIPAM hydrogel 2 is h 2 5μm, the thickness of the ultra-fine heating net 3 h 3 It is 5μm, mesh number is 6000, pore size is 2.5μm, the coating thickness of PAAm hydrogel Ⅰ1 and PAAm hydrogel Ⅱ4 on PNIPAM hydrogel 2 is h 4 It is 5μm. It is assumed that the height h of the triangular groove is 20 μm, the width s of the groove is 30 μm, and the interval f between adjacent triangles is 50 μm. The drag reduction rate of the smart hydrogel material with a sandwich structure is 6.29%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com