Compartment end surface sealing device

A technology of end face sealing and sealing device, which is applied in engine sealing, hull bulkhead, transportation and packaging, etc. It can solve the time-consuming and labor-intensive problems of disassembly and replacement, and achieve the effect of convenient maintenance, small size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

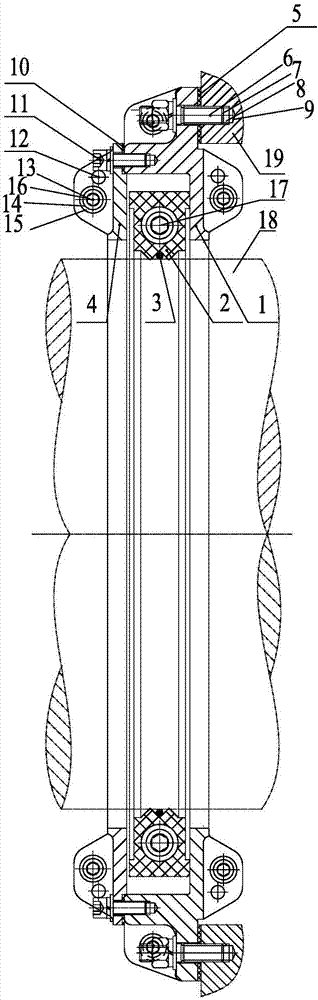

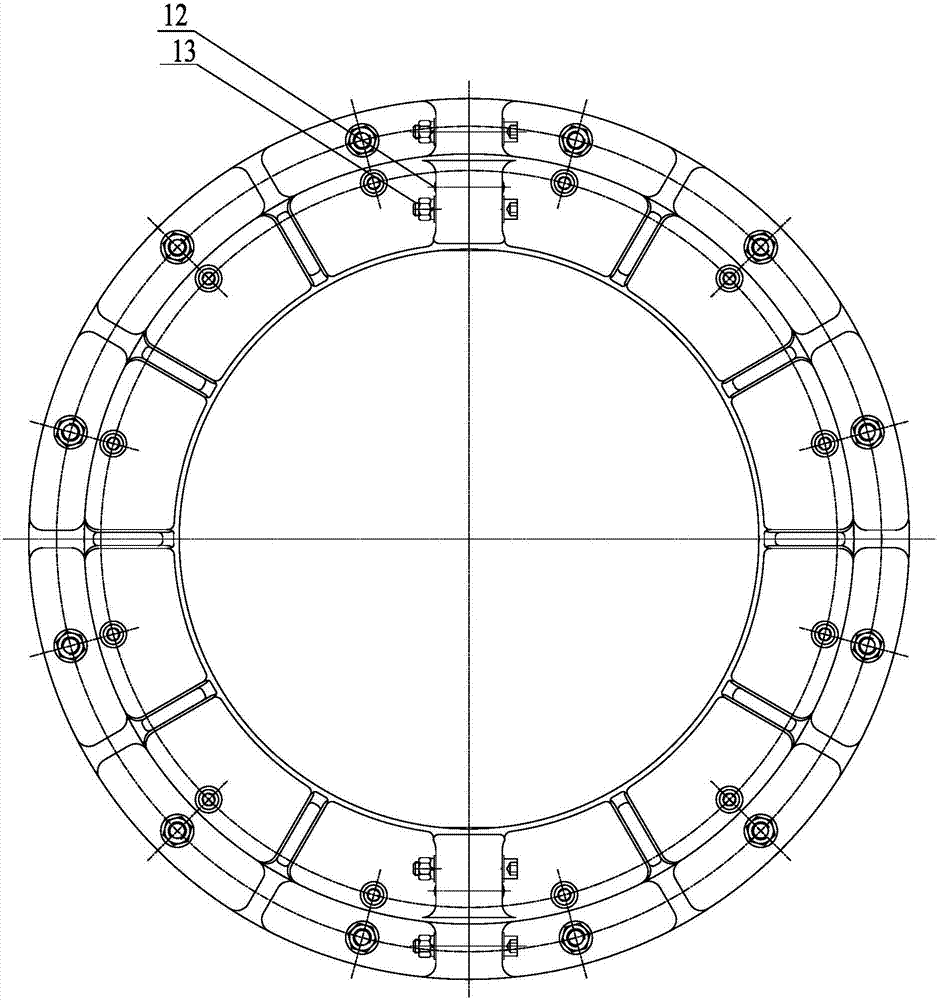

[0016] Such as Figure 1-Figure 2 As shown, a compartment end face sealing device, the sealing device is a fully split structure, including a base 1, a membrane disc 2, an O-ring 3 and a cover plate 4, and the base 1 is connected to the bulkhead 19 by a stud bolt 6 , the membrane disc 2 is slidingly sleeved on the ship shaft 18, and the surface of the ship shaft 18 is provided with an O-ring 3, and the membrane disc 2 presses the O-ring 3 on the surface of the ship shaft 18. The base 1 is a two-half structure, and the base The two parts of 1 are connected by bolts 13 and cylindrical pins 12. The outer side of the stud bolt 6 is provided with a first spring washer 7, a first flat washer 8 and a first nut 9 in sequence. The cover plate 4 is a two-half structure. Made of aluminum alloy, nickel-aluminum-bronze alloy or stainless steel, the two parts of the cover plate 4 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap