Workpiece assembling and distributing device

A distribution device and assembly device technology, which is applied in metal processing, manufacturing tools, conveyor objects, etc., can solve the problems of easy burning of motors, and achieve the effect of saving operation steps, convenient operation, and avoiding mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

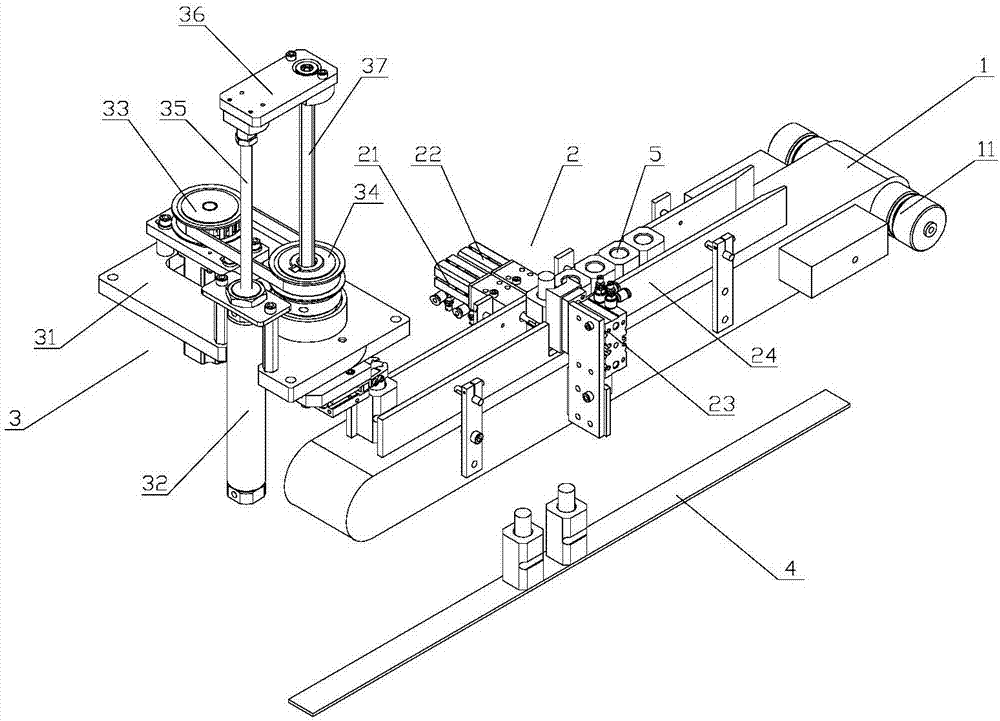

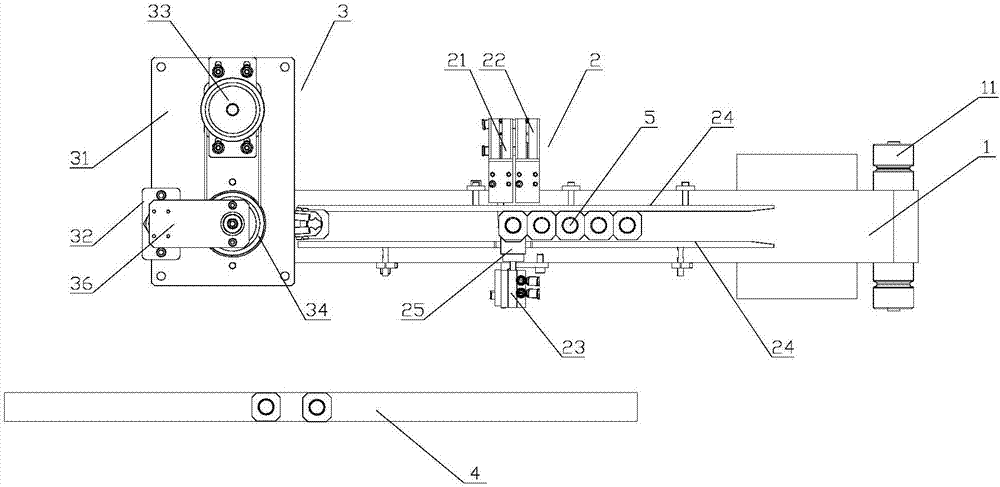

[0027] The orientations of the left side and the top in the present invention are limited to figure 1 The states shown are reference states.

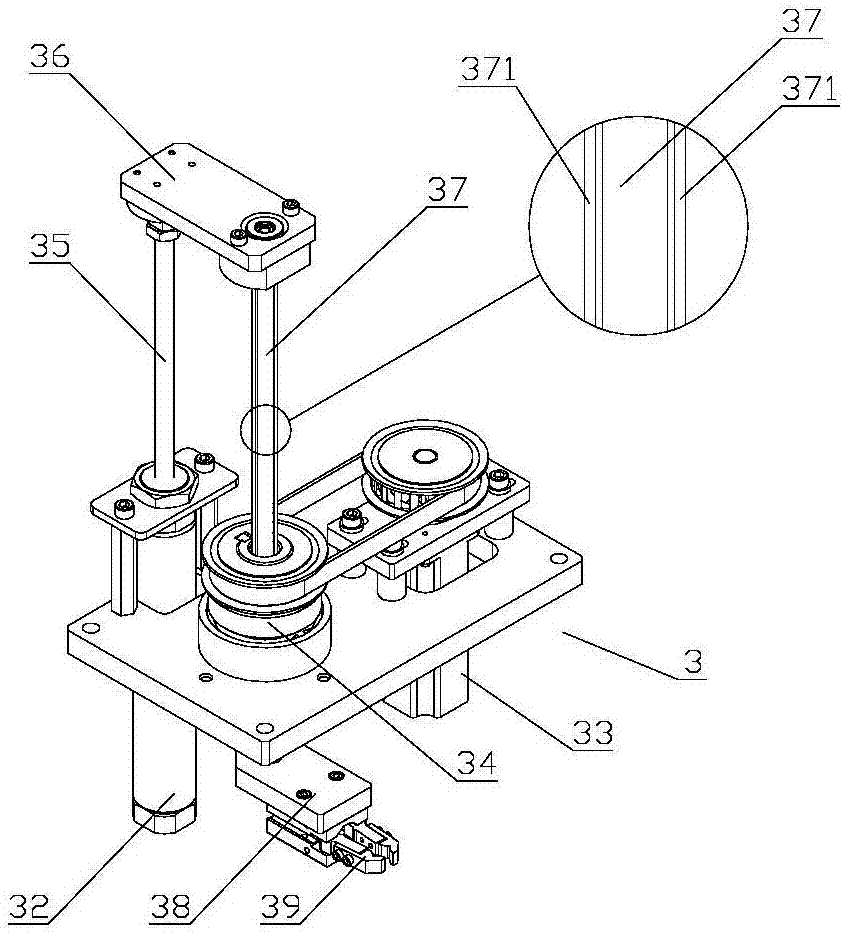

[0028] refer to figure 1 and figure 2 , a workpiece assembly and distribution device, including a conveying line 4 and a motor-driven conveyor belt 1, and also includes a positioning assembly device 2, a transfer distribution device 3 and a control cabinet, the positioning assembly device 2 is fixedly connected to the conveyor belt 1, the The transfer distribution device 3 is arranged above the conveyor belt 1; Figure 4 , the positioning assembly device 2 includes two oppositely placed limiting splints 24, a first cylinder 21, a second cylinder 22 and a positioning cylinder 23, a first positioning rod 26 that reciprocates in the first cylinder 21, and a first positioning rod 26 that moves back and forth. There is a reciprocating second positioning rod 27 in the second cylinder 22, the first positioning rod 26 and the second positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com