Self-walking balance-weight-free static pile pressing device

A static pressure pile, no counterweight technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problem of inconvenient disassembly and transportation, difficult to control the accuracy of pile formation, occupying a large work site, etc. problems, to achieve the effect of fast pile planting, precise control of pile planting accuracy, and small occupation of construction site.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

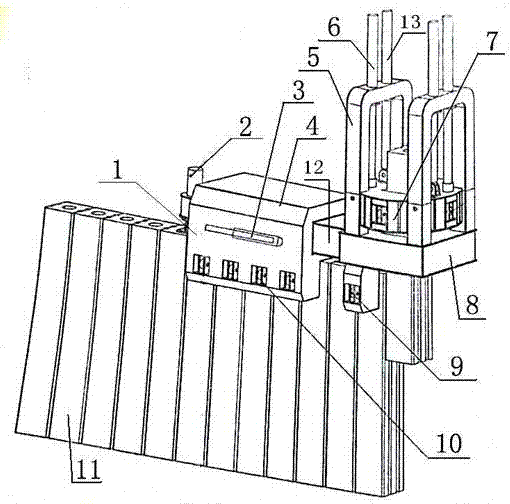

[0019] A kind of self-propelled static pile pressing equipment without counterweight, which is composed of a chassis, a clamping balance system, a pile pressing system and a moving system. The tightening is controlled by a positioning oil cylinder; the moving system is composed of a jacking oil cylinder arranged at the rear end of the chassis, a moving oil cylinder and a moving guide rail arranged on the chassis, and the pile pressing system is composed of a pile pressing frame and fixed on the pile pressing frame The pile pressure frame is set at the front end of the chassis, the pile pressure guide rail is provided on the guide rail frame, and the pile pressure clamp is slidable on the pile pressure guide rail, and the pile pressure clamp is inside A clamp oil cylinder is provided, and the pile-pressing oil cylinder and the vibrating device are all arranged on the pile-pressing guide rail.

[0020] The positioning oil cylinders are divided into two groups, and each group is ...

Embodiment 2

[0027] A kind of self-propelled static pile pressing equipment without counterweight, which is composed of a chassis, a clamping balance system, a pile pressing system and a moving system. Tightening / releasing is controlled by a positioning cylinder; the moving system is composed of a jacking cylinder arranged at the rear end of the chassis, a moving cylinder and a moving guide rail arranged on the chassis, and the pile pressing system is composed of a pile pressing frame and The pile frame is composed of a guide rail frame, a pile clamp, a vibration device, and a pile pressure cylinder. The pile load frame is arranged at the front end of the chassis. The inside of the pile clamp is provided with a clamp oil cylinder, and both the pile pressure cylinder and the vibration device are arranged on the pile pressure guide rail.

[0028] There are four groups of positioning oil cylinders, each group is two and arranged symmetrically.

[0029] The bottom of the track frame is also s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com