Gas pipeline water draining device with blockage preventing and gas isolating functions

A technology for gas pipelines and drains, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as difficulty in dredging, hidden dangers, inability to ensure the safety of gas pipelines, related equipment and personnel, etc. Safety, avoid leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

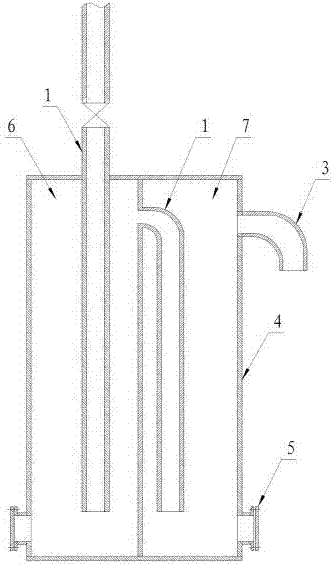

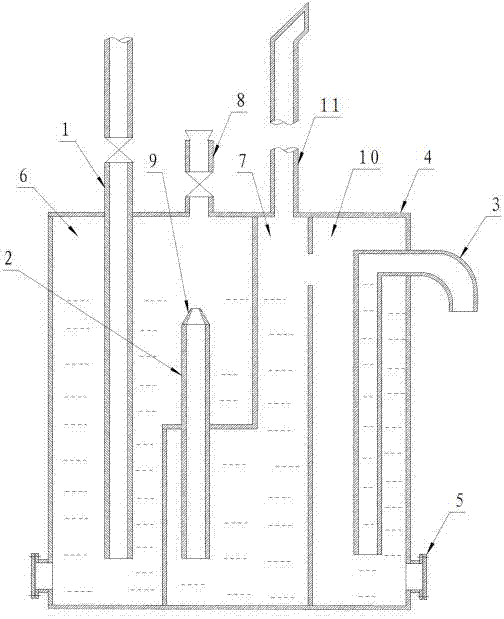

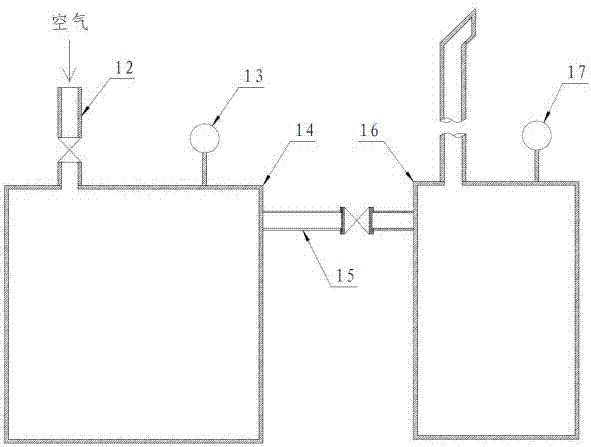

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] In the present invention, the gas drainer is designed as a "reliable partition device", which completely solves the current situation that the gas drainer is frequently blocked and difficult to maintain; at the same time, the problem that it is theoretically feasible but practically impossible to use should be avoided during design.

[0021] GB6222-2005 Gas Safety Regulations for Industrial Enterprises 7.2.3 classifies gas water seals as partition devices. At the same time, it is stipulated that when the water seal is used behind other partition devices, it is a reliable (gas) partition device. Thousands of gas drains currently running in enterprises can be equipped with valves in front, but the valves cannot be closed. Therefore, these gas drains are gas water seals for recovering condensed water, and are only gas cutoff devices, not reliable cutoff devices. It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com