Rock wool board on-line dimension measurement device

A technology for size detection and rock wool board, applied in the field of rock wool board online size detection device, can solve the problems of waste of personnel cost and increase of product failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

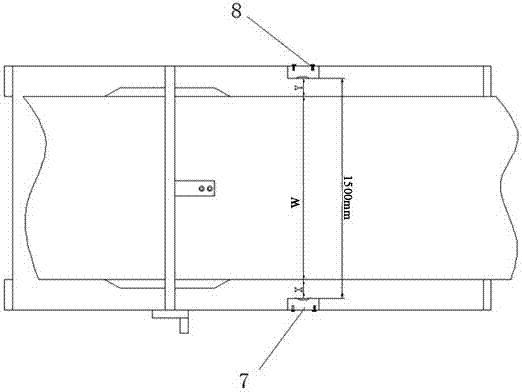

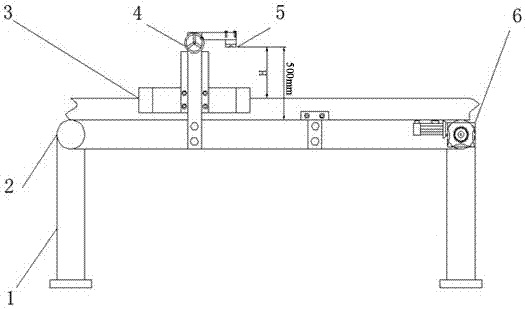

[0012] An online size detection device for rock wool boards, including a belt conveyor composed of a belt bracket 1, a belt 2 and a drive motor 6, and a set of positioning splints composed of a splint 3 and an adjusting screw rod 4, plus a laser An online detection device composed of range finder A7, laser range finder B8 and laser range finder C5. The belt conveyor drives the belt 2 to rotate through the driving motor 6. The bottom of the belt is supported by the belt bracket 1 to ensure the smooth transportation of the rock wool board. The splint 3 is used to ensure that the rock wool board walks along a straight line parallel to the production line when the rock wool board is conveyed In order to prevent the rock wool board from shifting to both sides, the position of the splint 3 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com