Clamp replaceable continuous engine leakage detection device and method

A technology for engines and engine casings, which is applied in the field of continuous engine leak detection devices with replaceable fixtures, can solve the problems of increased equipment investment and maintenance costs, inflexible use of leak detection devices, and high investment costs of leak detection devices. The effect of leak detection cycle, avoiding false detection, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

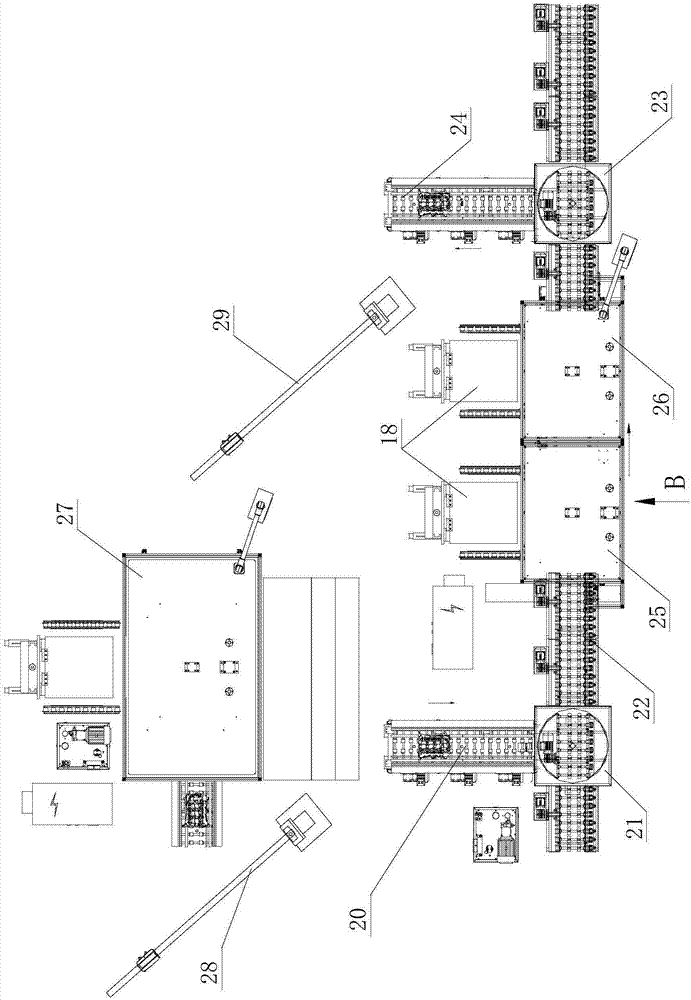

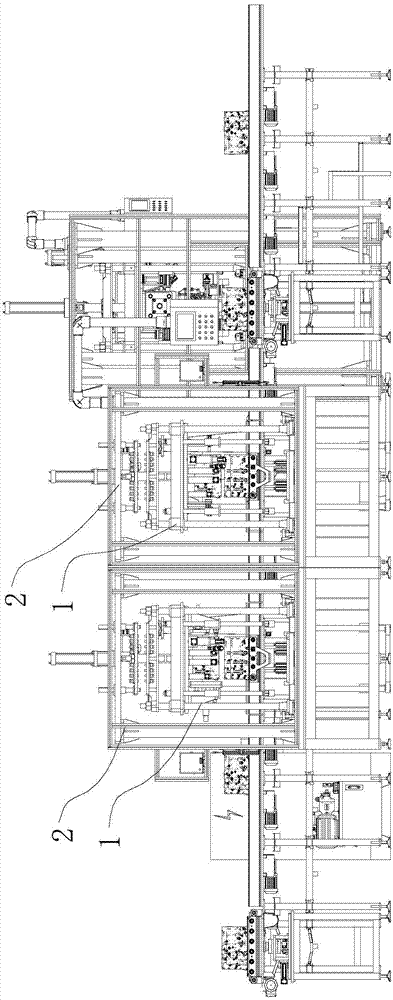

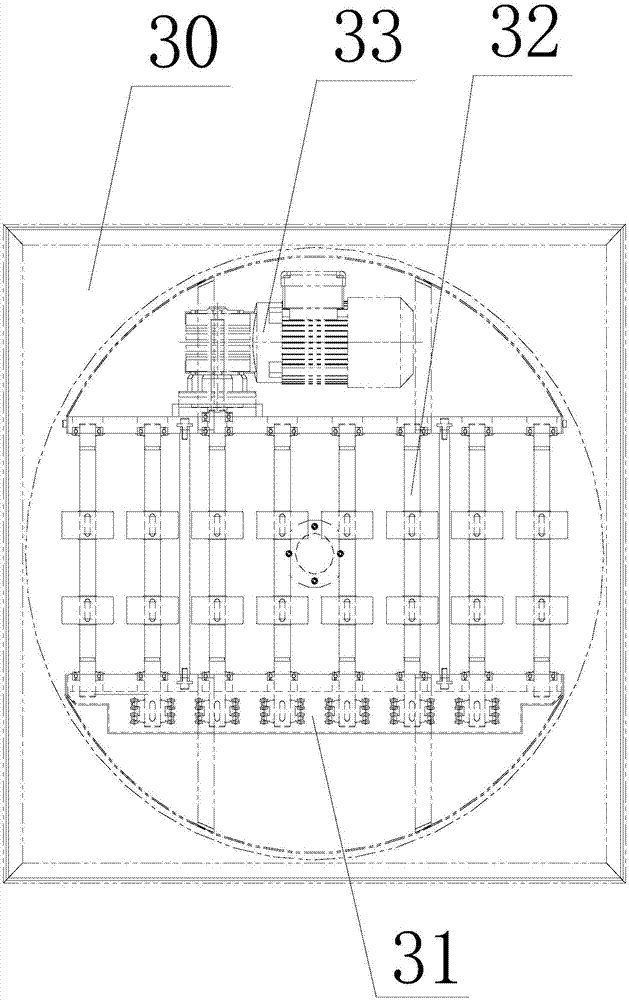

[0044] In this embodiment, a continuous engine leak detection device with replaceable clamps, such as figure 1 As shown, it includes the feeding raceway 20, the first turntable 21, the conveying raceway 22, the second turntable 23 and the discharge raceway 24 connected in sequence, and the crankcase leak detection station 25 and the oil and water channel inspection station are arranged on the conveying raceway. Leak station 26, a leak detection water tank 27 is arranged between the feed raceway and the discharge raceway, a first cantilever crane 28 is arranged between the feed raceway and the leak detection water tank, A second cantilever crane 29 is arranged between them; wherein, the first turntable and the second turntable are used for the conversion of the conveying direction of the engine case, and the crankcase leak detection station is used to detect whether the crankcase part of the engine case will leak, The oil and water channel leak detection station is used to dete...

Embodiment 2

[0054] In this embodiment, a continuous engine leak detection method with replaceable clamps is implemented by the device described in Embodiment 1, including the following steps:

[0055] (1) The engine casing as the workpiece enters from the feeding raceway, and enters the conveying raceway after passing through the first turntable;

[0056] (2) After the engine casing is sent to the crankcase leak detection station by the conveying raceway, it is clamped by the clamp on the crankcase leak detection station, and the engine casing is checked by a leak detector externally connected to the crankcase leak detection station. Carry out crankcase leak detection;

[0057] (3) After the crankcase leak detection is completed, the engine casing is sent to the oil and water channel leak detection station by the conveying raceway, and is clamped by the fixture on the oil and water channel leak detection station, and is connected to the oil and water channel leak detection station. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com