Complex scene production scheduling method and system based on quantum evolutionary algorithm

A quantum evolutionary algorithm and complex scene technology, which is applied in the production scheduling method and system field of complex scenes based on quantum evolutionary algorithm, can solve the problems of short production scheduling time and low utilization rate of storage raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110] The present invention will be further described below with reference to the accompanying drawings and embodiments.

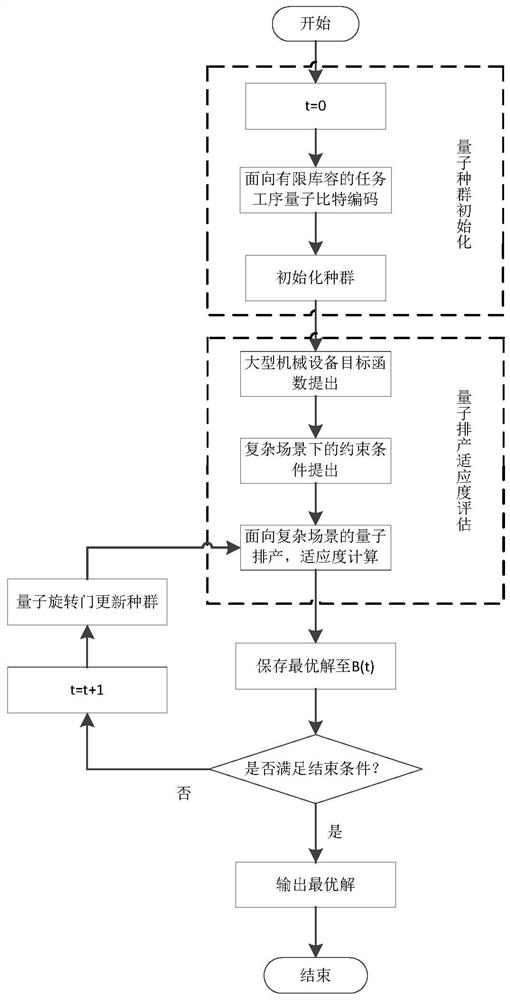

[0111] like figure 1 As shown, the production scheduling method for complex scenarios based on quantum evolutionary algorithm includes the following steps:

[0112] Step (1) Quantum population initialization; including initializing quantum population evolution algebra, initializing qubit encoding and initializing the number of quantum chromosomes;

[0113] Step (1-1) Initialize the evolutionary algebra t=0.

[0114] Step (1-2) Initialize the qubit code: by determining the machine selected for the large-scale mechanical equipment work order task and the order of on-line processing, a better quantum objective function can be obtained.

[0115] Two variables need to be defined during initialization:

[0116] The first variable indicates whether the jth process of the work order i is processed on the kth machine, which is recorded as variable a ijk , if m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com