Multifunctional industrial robot gripper

An industrial robot, multi-functional technology, applied in manipulators, manufacturing tools, chucks, etc., can solve the problem of fingers affecting work efficiency, and achieve the effects of easy manufacturing, improved processing accuracy, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

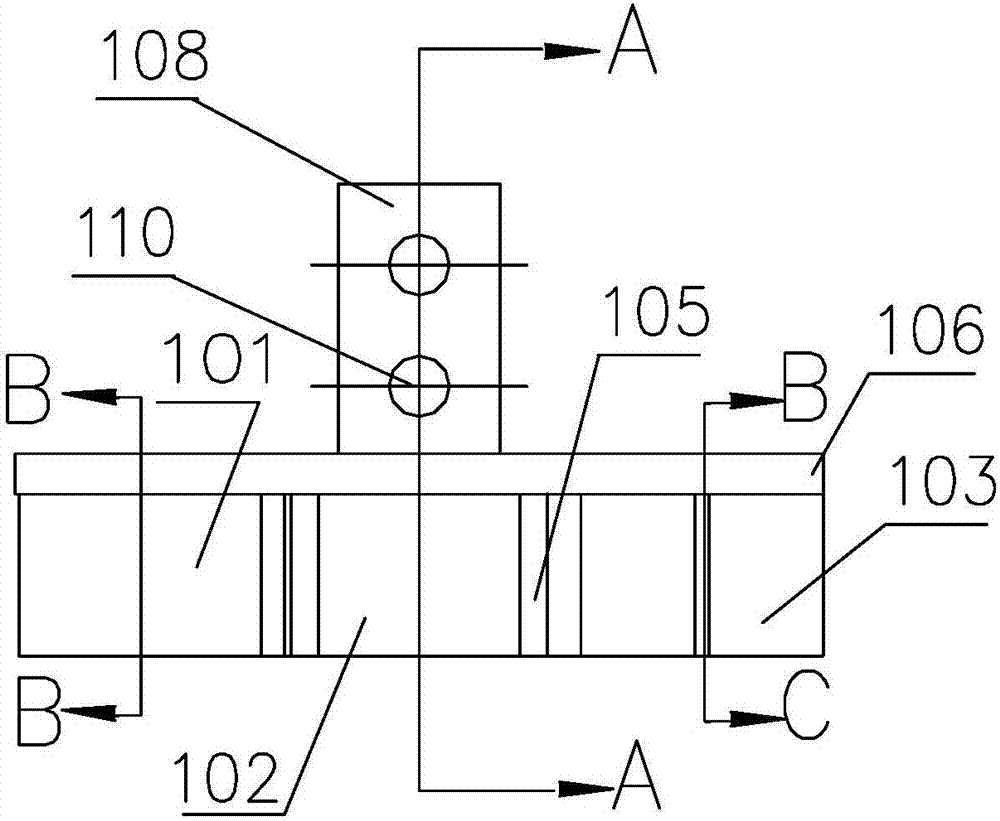

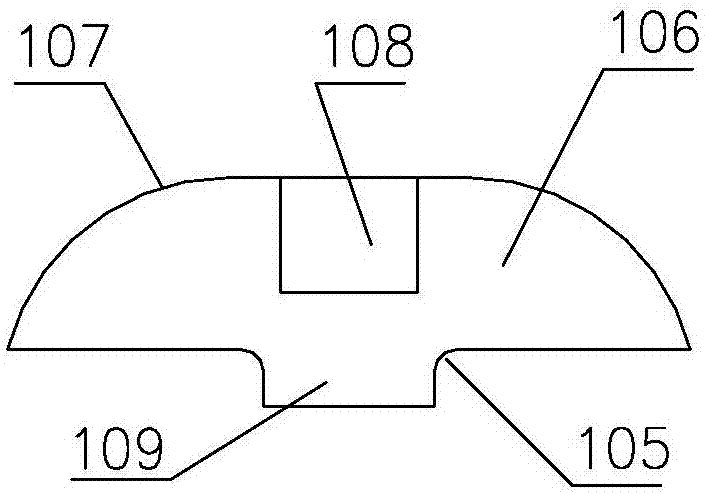

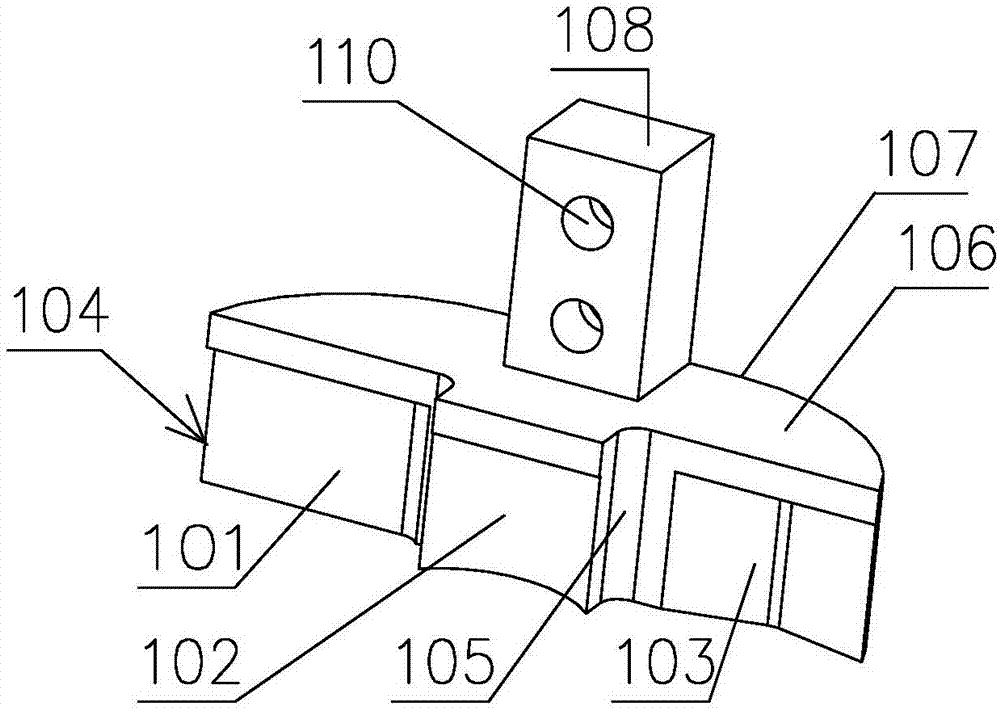

[0035] A multifunctional industrial robot gripper of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0036] A multi-functional industrial robot gripper of the present invention adopts a multi-shaped surface clamping design, which is respectively a parallel plane clamping part, a diamond-shaped surface clamping part, and a cylinder clamping part. The clamping part of the parallel plane, the clamping part of the diamond surface, and the clamping part of the cylindrical surface constitute the end operation part of the whole robot. The connection between the fingers and the hand is achieved by pins. Whether the robot finger can accurately grip the workpiece and send the workpiece to the designated position depends not only on the positioning accuracy of the manipulator, but also on the clamping error of the finger and the installation and positioning accuracy of the robot finger.

[0037] Such as figure 1 -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com