A driving joint suitable for high and low temperature environment in deep space

A high-low temperature, joint technology, used in electromechanical devices, joints, manipulators, etc., can solve the problems of small adaptable temperature range, low positioning accuracy, small transmission torque, etc., to achieve a wide adaptable temperature range, high shaft stiffness, transmission high torque effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

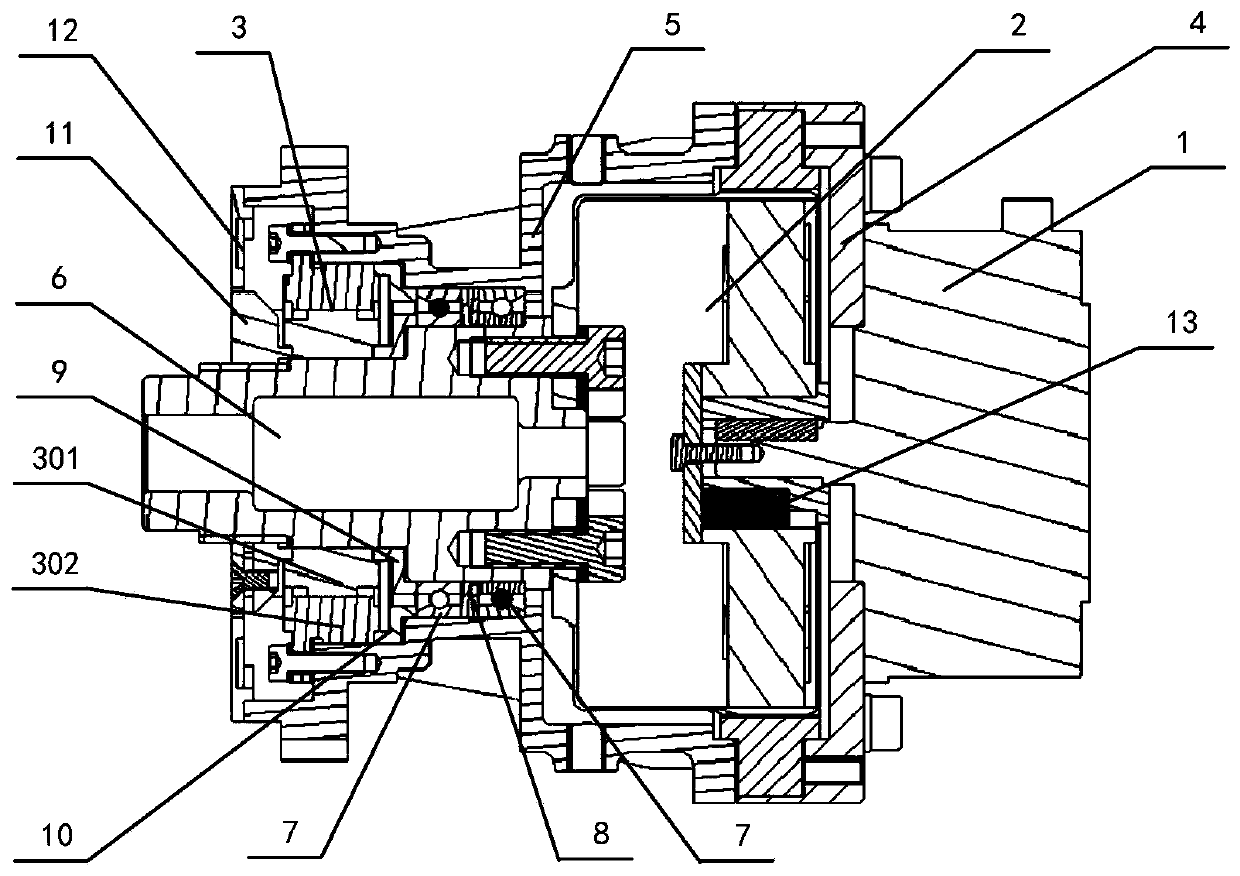

[0021] Below in conjunction with accompanying drawing, the present invention is described in detail:

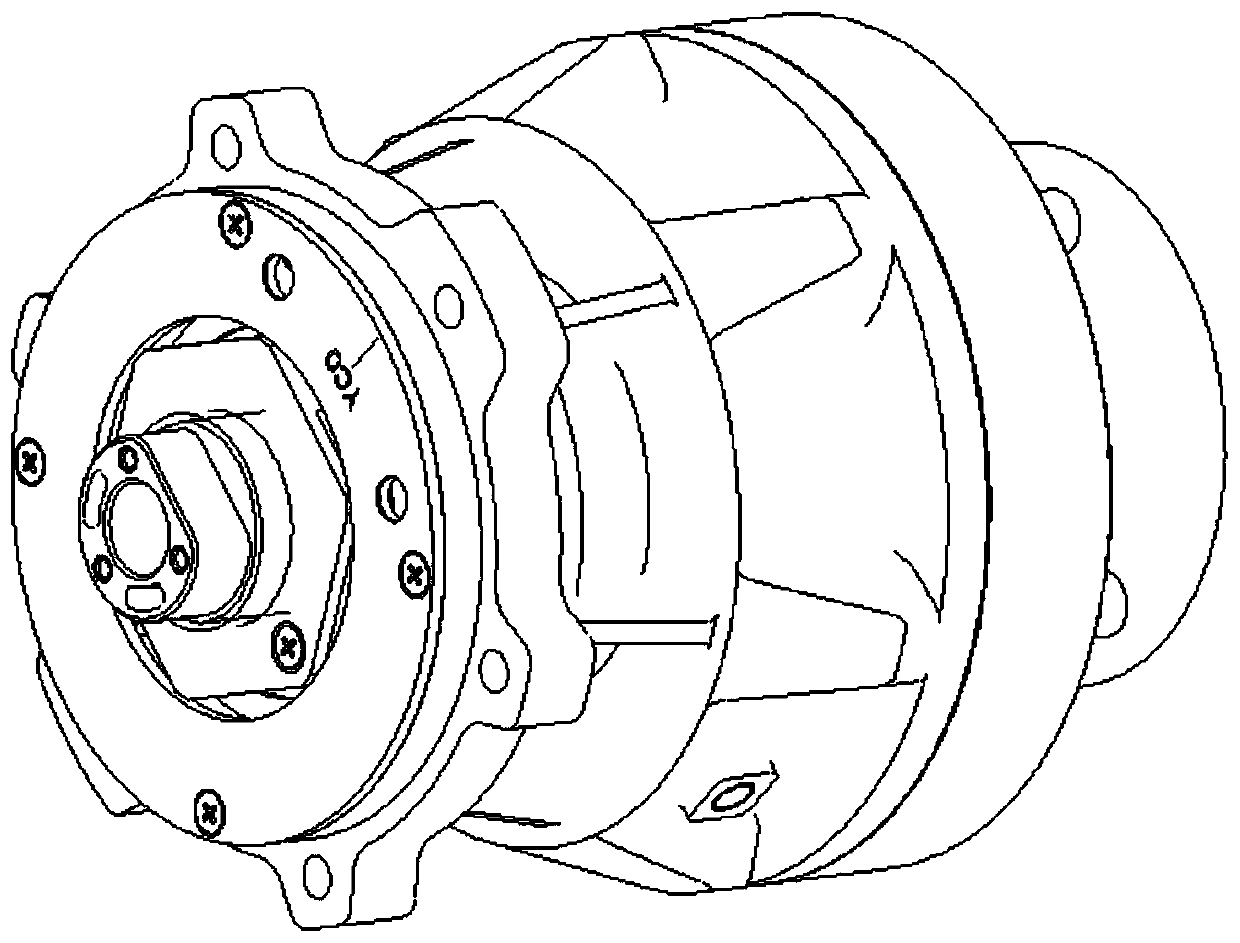

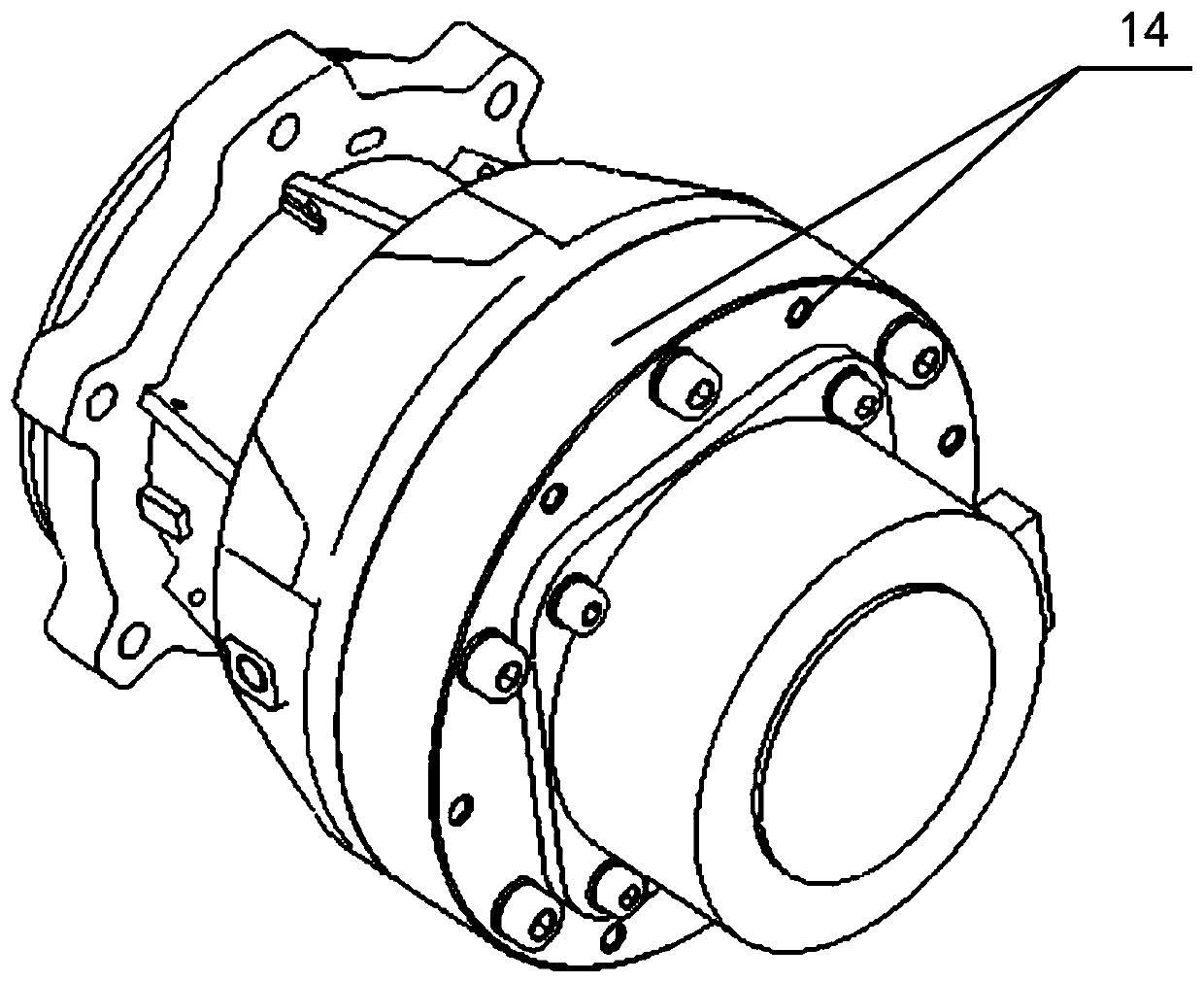

[0022] The present invention provides a drive joint suitable for high and low temperature environments in deep space. The mechanism includes: a stepping motor 1, a short-cup harmonic reducer 2, a rotary transformer 3, a casing end cover 4, a casing 5, an output shaft 6. Angular contact bearing 7, disc spring 8, inner bushing 9, outer bushing 10, stop nut 11 and bearing end cover 12.

[0023] The stepper motor 1 and the housing end cover 4 are positioned through the spigot and fixed by screw connection; the output shaft of the stepper motor 1 is fixedly connected with the input end of the short-cup harmonic reducer 2, and the flat key 13 is used for torque transmission. ; The fixed end of the short-cup harmonic reducer 2 is installed between the shell end cover 4 and the shell 5, and the three are fixed in series with a set of screws, wherein the gap between the shell end cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com