Method for Quickly Removing Compaction Dross During the Production of Aluminum-Zinc-Silicon GL

A technology of galvanizing, aluminum-zinc-silicon coating, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve problems such as harsh operating environment, average effect, and hardening, so as to improve the surface quality of products and shorten the Effects of cleaning time and reducing cleaning difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

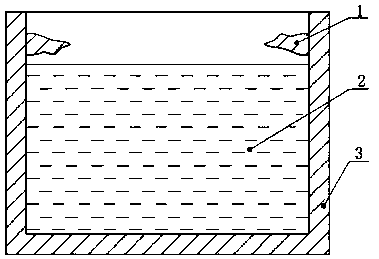

[0021] Embodiment 1: Taking slag removal as an example, the transition material is produced without stopping the vehicle. The specific process steps are as follows.

[0022] Before cleaning the slag, the distance of the specific liquid surface of the plate slag circle is 2cm, the height of the slag circle is 2cm, and the surface area of the zinc pot is 14m 2 , the calculation shows that the volume of Al-Zn-Si ingot to be added is 0.56m 3 ; Add aluminum-zinc-silicon ingots to submerge the liquid surface of the zinc pot to harden the scum. Keep the zinc pot sensor running at high power, raise the temperature of the zinc liquid in the zinc pot to 650°C, and keep it warm for 0.5 hours according to the dissolution of the hardened scum to fully soften the hardened scum, and then manually use the scum scraper to clean the scum. After cleaning the scum, reduce the power of the zinc pot sensor to reduce the temperature of the zinc liquid to 600±5°C. After the liquid level and tempe...

Embodiment 2

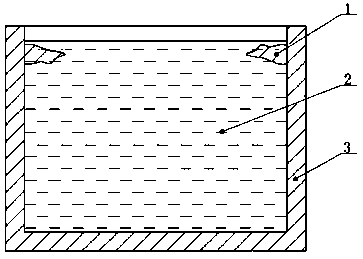

[0023] Embodiment 2: Taking slag removal as an example, the transition material is produced without stopping the vehicle. The specific process steps are as follows.

[0024] Before cleaning the slag, the distance of the specific liquid surface of the plate slag circle is 4cm, the height of the slag circle is 3cm, and the surface area of the zinc pot is 14m 2 , the calculation shows that the volume of Al-Zn-Si ingot to be added is 0.98m 3 ; Add aluminum-zinc-silicon ingots to submerge the liquid surface of the zinc pot to harden the scum. Keep the zinc pot sensor running at high power, increase the temperature of the zinc liquid in the zinc pot to 660°C, and keep it warm for 1 hour according to the dissolution of the hardened scum to fully soften the hardened scum, and then manually use the scum remover to clean the scum. After cleaning the scum, reduce the power of the zinc pot sensor to reduce the temperature of the zinc liquid to 600±5°C. After the liquid level and tempe...

Embodiment 3

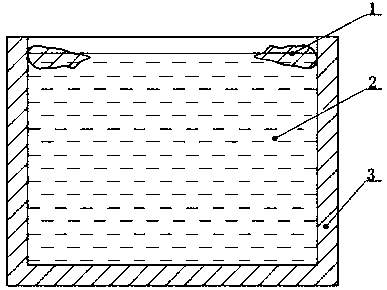

[0025] Embodiment 3: Taking the slag cleaning combined with the replacement of three rollers and six arms requiring parking as an example, the specific process steps are as follows.

[0026] Before the production of GL slag removal, the distance of the specific liquid surface of the plate slag circle is 2cm, the height of the slag circle is 3cm, and the surface area of the zinc pot is 14m 2 , the calculation shows that the volume of Al-Zn-Si ingot to be added is 0.7m 3 ; Add aluminum-zinc-silicon ingots to submerge the liquid surface of the zinc pot to harden the scum. Keep the zinc pot sensor running at high power, raise the temperature of the zinc liquid in the zinc pot to 640°C, and keep it warm for 0.5 hours according to the dissolution of hardened scum to fully soften the hardened scum, and then manually use the scum remover to clean the scum. After clearing the slag, put in a new three-roller six-arm and air knife; after replacing the three-roller six-arm, reduce the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com