Integrated slag discharge device for drill carriage

An all-in-one, drilling rig technology, applied in drilling, drilling equipment, earth-moving drilling with mechanical conveying devices, etc., can solve the problem that pulverized coal needs to be cleaned manually, so as to reduce the labor intensity of employees, improve work efficiency, The effect of the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

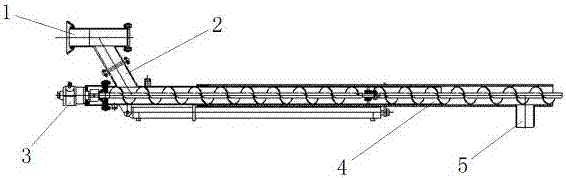

[0021] An integrated slag discharge device for drilling rigs, such as figure 1 As shown, the device includes a pulverized coal collection cylinder 1, a connecting cylinder 2, an air motor 3, a screw conveyor 4, and a pulverized coal outlet 5, wherein one end of the screw conveyor 4 is connected to the connecting cylinder 2, and the other end of the screw conveyor 4 There is a pulverized coal outlet 5 below the pulverized coal collection cylinder 1 connected to the upper end of the connection cylinder 2, the pulverized coal collection cylinder 1 is in a horizontal state, the air motor 3 is connected to the screw conveyor 4, and the rotating shaft of the air motor 3 is connected to the screw conveyor. The screws of the conveyor 4 are connected.

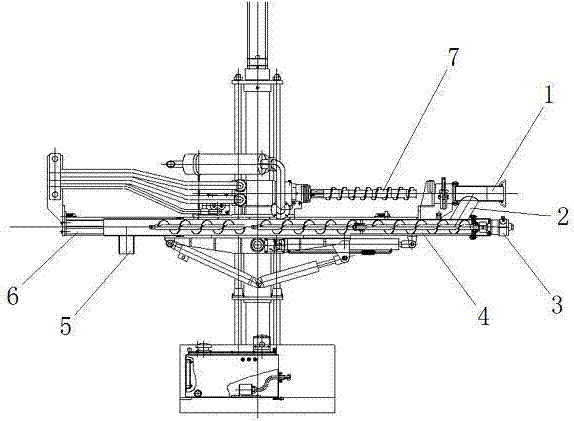

[0022] The state when the device is applied to the CMQS1-400 / 5.2S deep hole pneumatic drilling rig is as follows figure 2 As shown, the device as a whole is fixedly connected to the drilling car guide rail 6 places, and simultaneously...

Embodiment 2

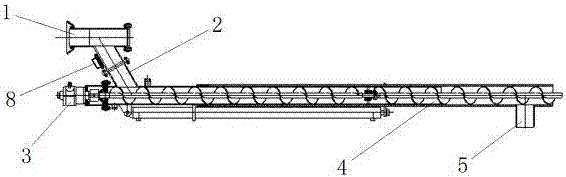

[0025] An integrated slag discharge device for drilling rigs, such as image 3 As shown, it includes a pulverized coal collection cylinder 1, a connecting cylinder 2, an air motor 3, a screw conveyor 4, and a pulverized coal outlet 5, wherein one end of the screw conveyor 4 is connected to the connecting cylinder 2, and the other end of the screw conveyor 4 is connected below There is a pulverized coal outlet 5, the pulverized coal collection cylinder 1 is connected to the upper end of the connection cylinder 2, the pulverized coal collection cylinder 1 is in a horizontal state, the air motor 3 is connected to the screw conveyor 4, and the rotating shaft of the air motor 3 is connected to the screw conveyor 4 screws are connected.

[0026] On the basis of the above technical solutions, the following conditions are met:

[0027] The angle between the axis of the connecting cylinder 2 and the axis of the screw conveyor 4 is 60°.

[0028] The pulverized coal outlet 5 is a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com