A kind of thermal detector and its preparation method

A heat detector and thermistor layer technology, applied in the direction of electric radiation detectors, semiconductor devices, final product manufacturing, etc., can solve the problem of inability to realize narrow spectral range infrared intensity detection, infrared light screening, and inability to realize narrow spectral range infrared Detection and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

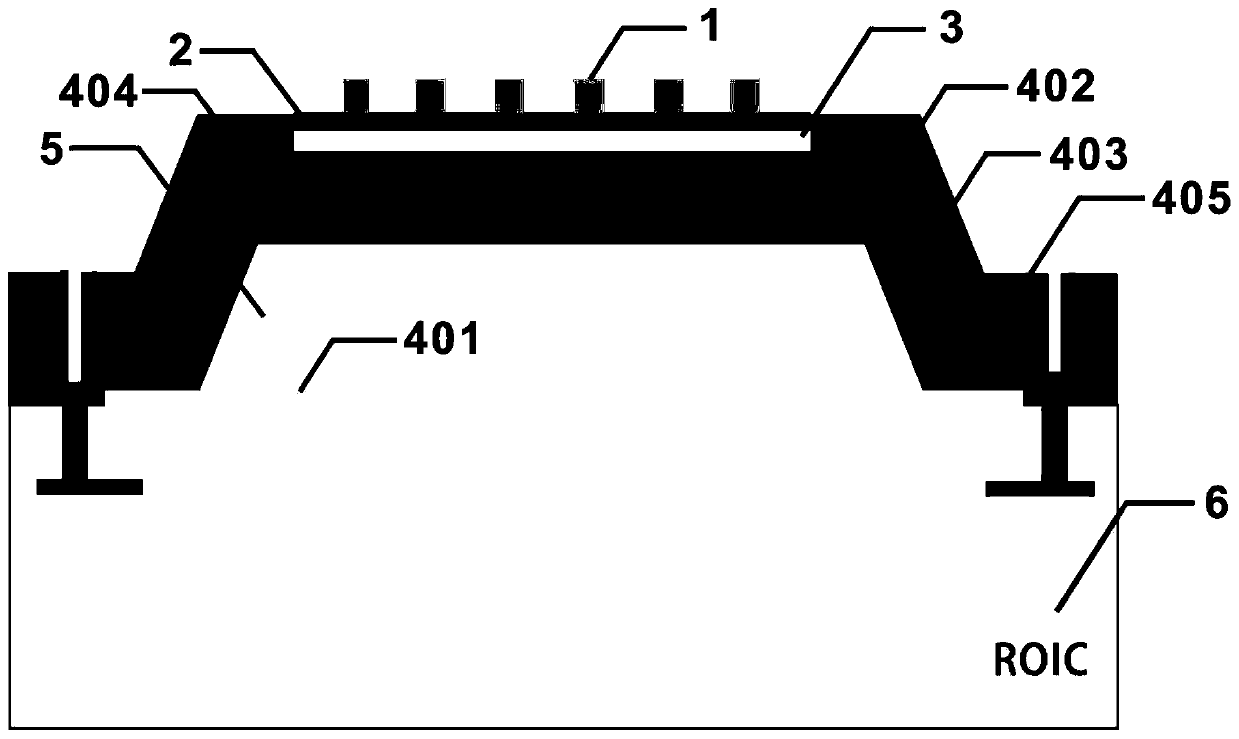

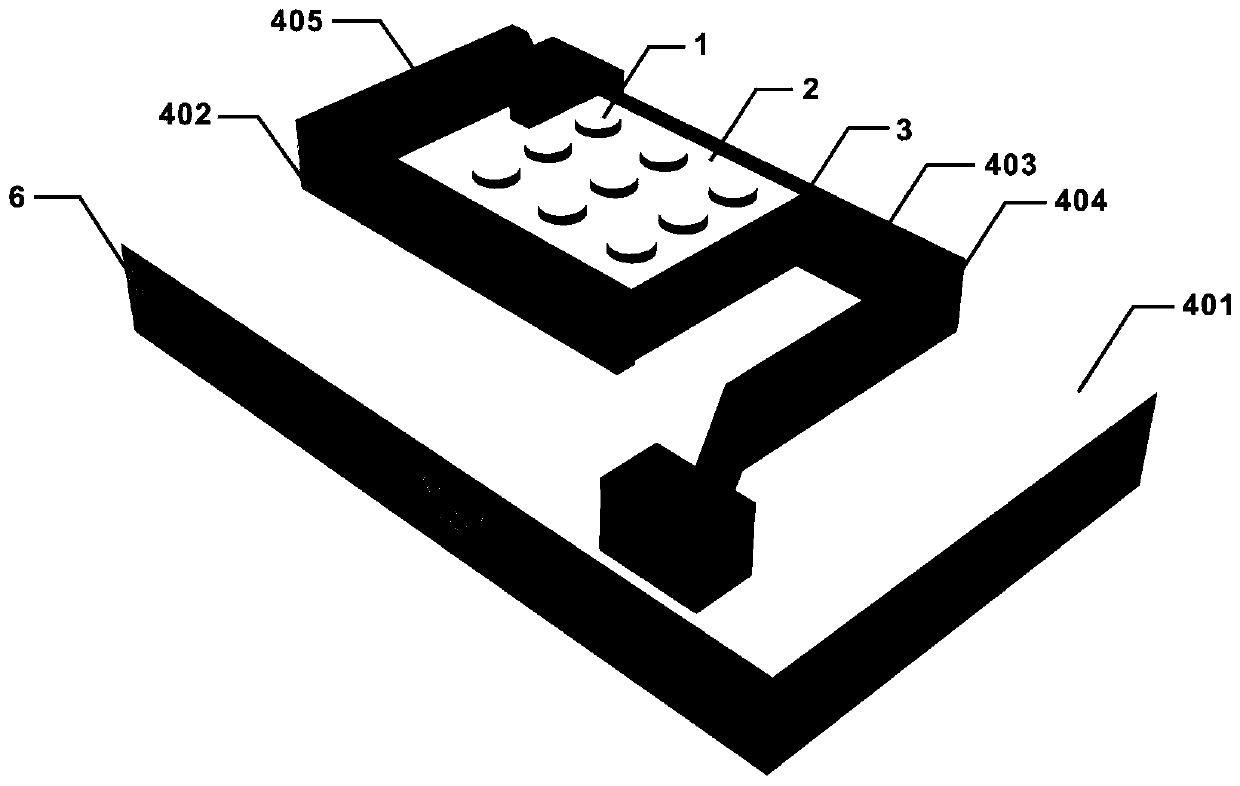

[0055] The first embodiment of the preparation method of the thermal detector provided by the present invention includes the following steps:

[0056] S1, clean the silicon wafer 6, and use plasma-enhanced chemical vapor deposition equipment to grow a layer of Si after drying 3 N 4 , with a thickness of 100-200 nm, used as the second passivation layer 401 to obtain a second substrate;

[0057] Spin-coat a layer of polyimide photoresist 5 on the second passivation layer 401 of the second substrate, the thickness is 1-3um, and carry out photolithography treatment to make the polyimide photoresist be a few characters, and then performing thermal curing treatment to form a sacrificial layer to obtain a seventh intermediate product;

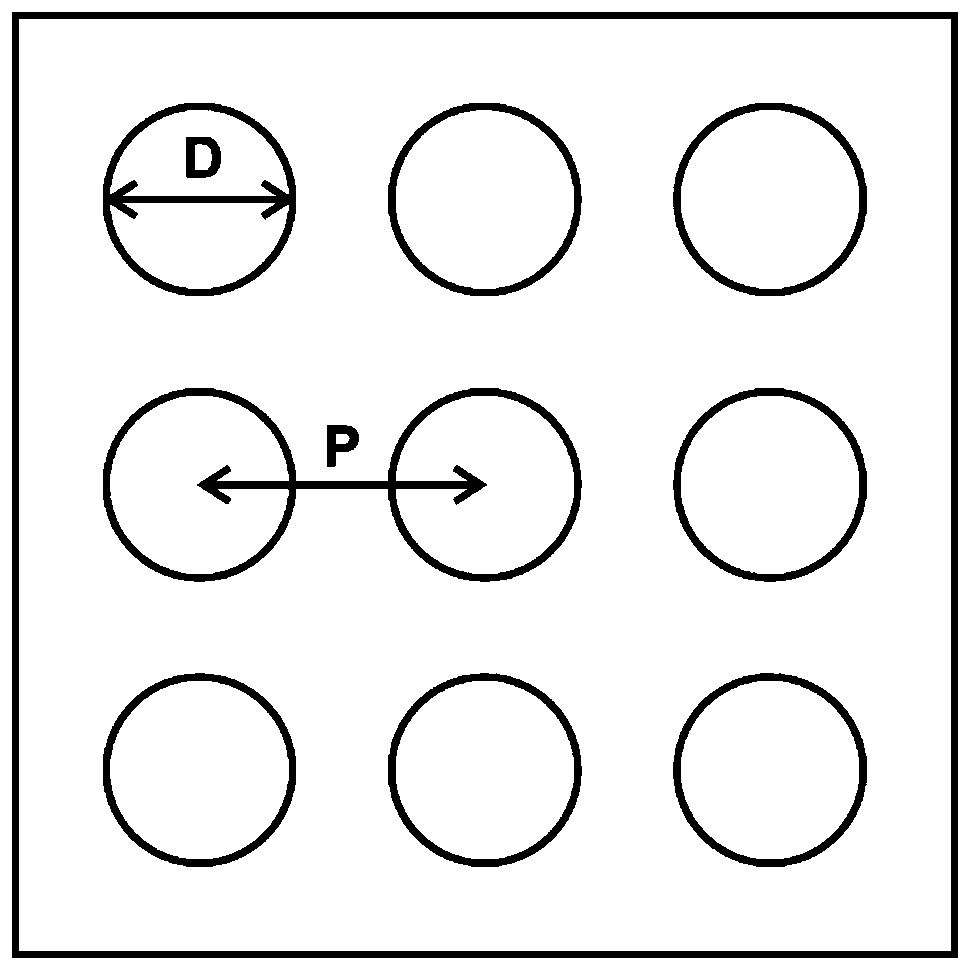

[0058] On the surface of the sacrificial layer of the seventh intermediate product, a layer of Si is grown using plasma-enhanced chemical vapor deposition equipment 3 N 4 A thin film with a thickness of 400-600nm to form a support layer 402 to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com