Variable line structure light guide plate and optical module

A light guide plate and line technology, applied in the field of optics, can solve problems such as dot duplication, unsatisfaction, mesh collision interference, etc., and achieve the effects of benefiting printing stability, avoiding dot interference texture, and reducing the use of covering films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

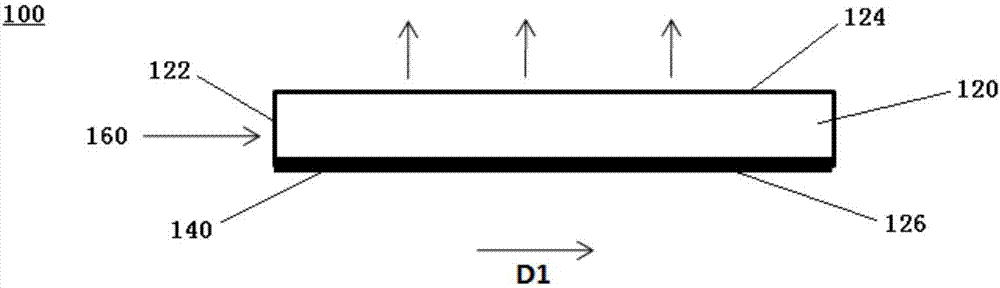

[0035] Please refer to figure 1 , is a structural schematic diagram of a light guide plate with a variable line structure provided by the present invention. The light guide plate 100 in this embodiment can be applied to a backlight module or a lighting fixture. The light guide plate 100 includes a main body 120 and a variable line structure 140. The variable line structure 140 is arranged on the main body 120. Through the variable line structure 140, it can At the same time, the light collecting degree of the light guide plate 100 is changed and the optical trend of light emitted after entering the light guide plate 100 is adjusted.

[0036] In the light guide plate 100, the main body 120 can be a light-transmitting plate or other equivalent light-transmitting parts. The main body 120 mainly includes a light incident surface 122, a first main surface 124, and a second main surface 126. The first main surface 124 and the second main surface The two main surfaces 126 are respec...

Embodiment 2

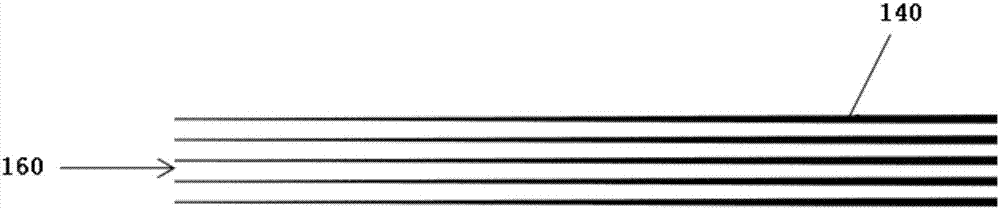

[0045] Such as Figure 6 As shown, it is the second embodiment of the present invention. In this embodiment, the variable lines in the variable line structure 140 form an angle of 45° or 135° with the light incident surface 122, and each independent variable line has a Generate a variable process, the narrower the width of the lines closer to the light incident surface 122, the wider the farther away from the light incident surface 122; there is no variable relationship between adjacent lines parallel to the light incident surface 122, relative to the light incident surface 122 Non-parallel surfaces produce a variable relationship. The closer to the light incident surface 122, the narrower the width of the lines, and the farther away from the light incident surface 122, the wider the width of the lines. The central axes of two adjacent variable lines are parallel to each other.

Embodiment 3

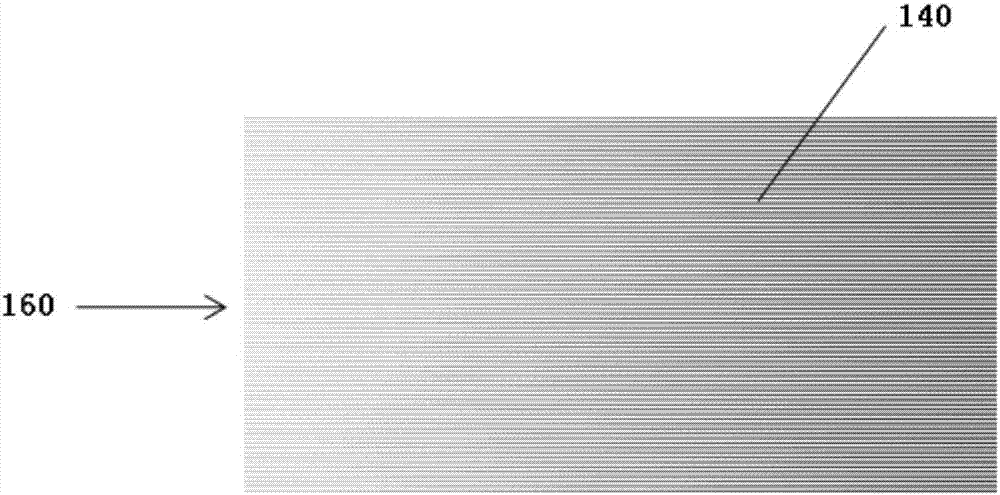

[0047] Such as Figure 7 As shown, it is the third embodiment of the present invention. In this embodiment, the variable lines in the variable line structure 140 form an angle of 0° or 180° with the light incident surface 122, and the variable lines are parallel to the light incident surface 122. On surface 122, there is no variable process on each independent variable line, and its width is fixed, but a variable relationship is formed between adjacent variable lines in turn. The closer to the light incident surface 122, the narrower the width of the line, and the farther away from the light incident surface The wider the line width of 122 is, the central axes of two adjacent variable lines are parallel to each other.

[0048] The manufacturing method of the variable line structure light guide plate provided by the above-mentioned embodiments 1 to 3 includes the following steps:

[0049] S1: According to the requirements of the diaphragm covering in the module design, establi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com