Yak yogurt powder and preparation method thereof

A technology of yak acid and milk powder, applied in the field of food processing, can solve the problems of low production efficiency, inability to preserve the health care and functional factors of fresh milk, etc., achieves low water content, considerable social and economic benefits, and ensures nutrition and health care. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

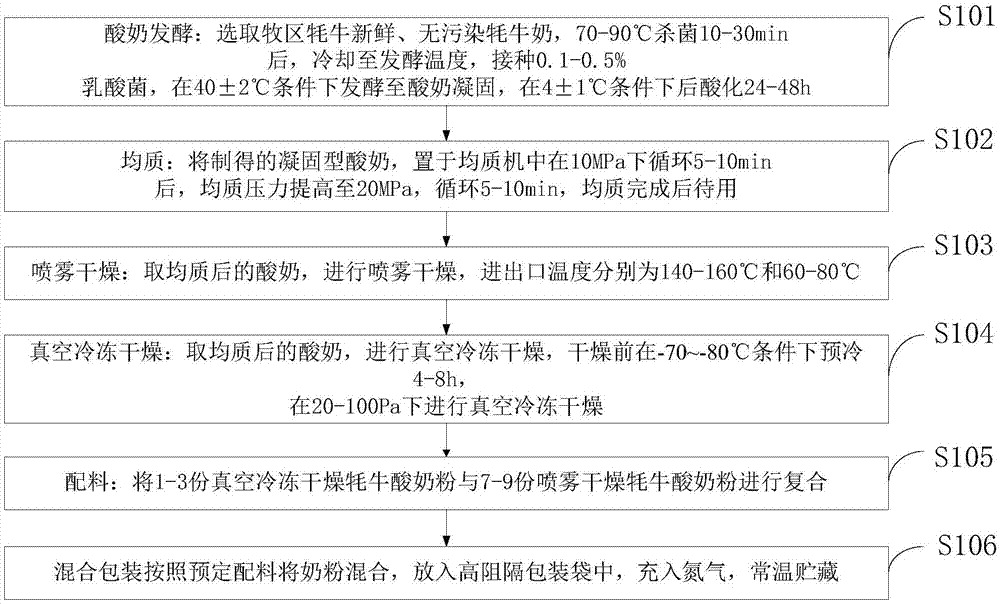

[0027] Such as figure 1 As shown, the yak yoghurt powder and preparation method thereof provided by the embodiments of the present invention include:

[0028] S101: Fermentation of yogurt: Select fresh, non-polluted yak milk from yaks in pastoral areas, sterilize at 70-90°C for 10-30 minutes, cool to the fermentation temperature, inoculate 0.1-0.5% lactic acid bacteria, and ferment at 40±2°C until the yogurt solidifies. Post-acidify at 4±1°C for 24-48h.

[0029] S102: Homogenization: Put the prepared solidified yogurt in a homogenizer and circulate at 10MPa for 5-10min, increase the homogenization pressure to 20MPa, circulate for 5-10min, and wait for use after homogenization is completed.

[0030] S103: spray drying: take the homogenized yoghurt and spray dry it, and the inlet and outlet temperatures are 140-160°C and 60-80°C respectively.

[0031] S104: Vacuum freeze-drying: take the homogenized yoghurt, carry out vacuum freeze-drying, pre-cool at -70-80° C. for 4-8 hours ...

Embodiment 1

[0036] The yak yoghurt powder and preparation method thereof provided by the embodiments of the present invention include:

[0037] A. Yogurt fermentation:

[0038] Select fresh, non-polluting yak milk from yaks in pastoral areas, sterilize at 80°C for 15 minutes, cool to the fermentation temperature, inoculate with 0.2% lactic acid bacteria, ferment at 40°C until the yogurt solidifies, and then acidify at 4±1°C for 24 hours.

[0039] B. Homogeneous:

[0040] Place the prepared coagulated yoghurt in a homogenizer and circulate it at 10 MPa for 8 minutes, increase the pressure of homogenization to 20 MPa, circulate it for 8 minutes, and wait for use after the homogenization is completed.

[0041] C. Spray drying:

[0042] The homogenized yoghurt was taken and spray-dried, and the inlet and outlet temperatures were 150°C and 70°C, respectively.

[0043] D. Vacuum freeze drying:

[0044] The homogenized yoghurt was taken, vacuum freeze-dried, pre-cooled at -70°C for 6 hours b...

Embodiment 2

[0050] The yak yoghurt powder and preparation method thereof provided by the embodiments of the present invention include:

[0051] Yogurt fermentation: select fresh, pollution-free yak milk from pastoral areas, sterilize at 70°C for 10 minutes, cool to the fermentation temperature, inoculate with 0.1% lactic acid bacteria, ferment at 40°C until the yogurt solidifies, and then acidify at 4°C for 24 hours.

[0052] Homogenization: put the prepared solidified yoghurt in a homogenizer and circulate it at 10MPa for 5 minutes, increase the pressure of homogenization to 20MPa, and circulate it for 5 minutes. After the homogenization is completed, it is ready for use.

[0053] Spray drying: Take the homogenized yogurt and spray dry it. The inlet and outlet temperatures are 140-160°C and 60°C respectively.

[0054] Vacuum freeze-drying: take the homogenized yogurt, carry out vacuum freeze-drying, pre-cool at -70~-80°C for 4 hours before drying, and carry out vacuum freeze-drying.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com