Copper buckle machining equipment and method for copper pipe packaging

A processing equipment and packaging technology, which is applied in the field of copper buckle processing equipment for copper tube packaging, can solve problems such as interference and interruption of equipment operation, and achieve the effects of superior overall stability, high degree of automation, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

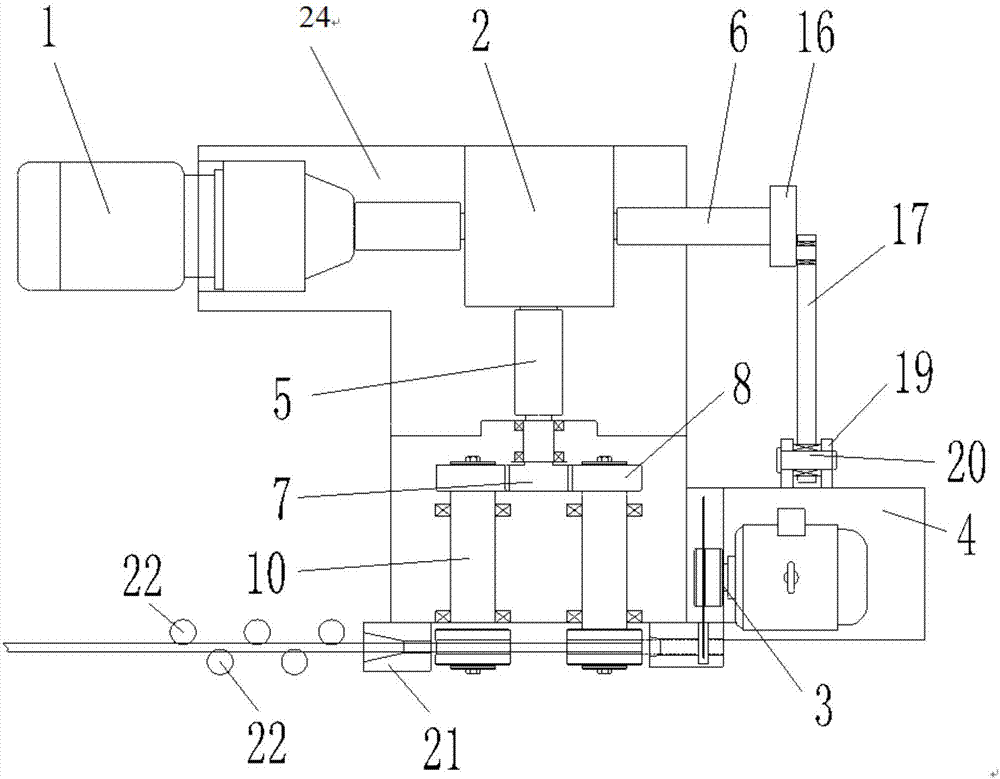

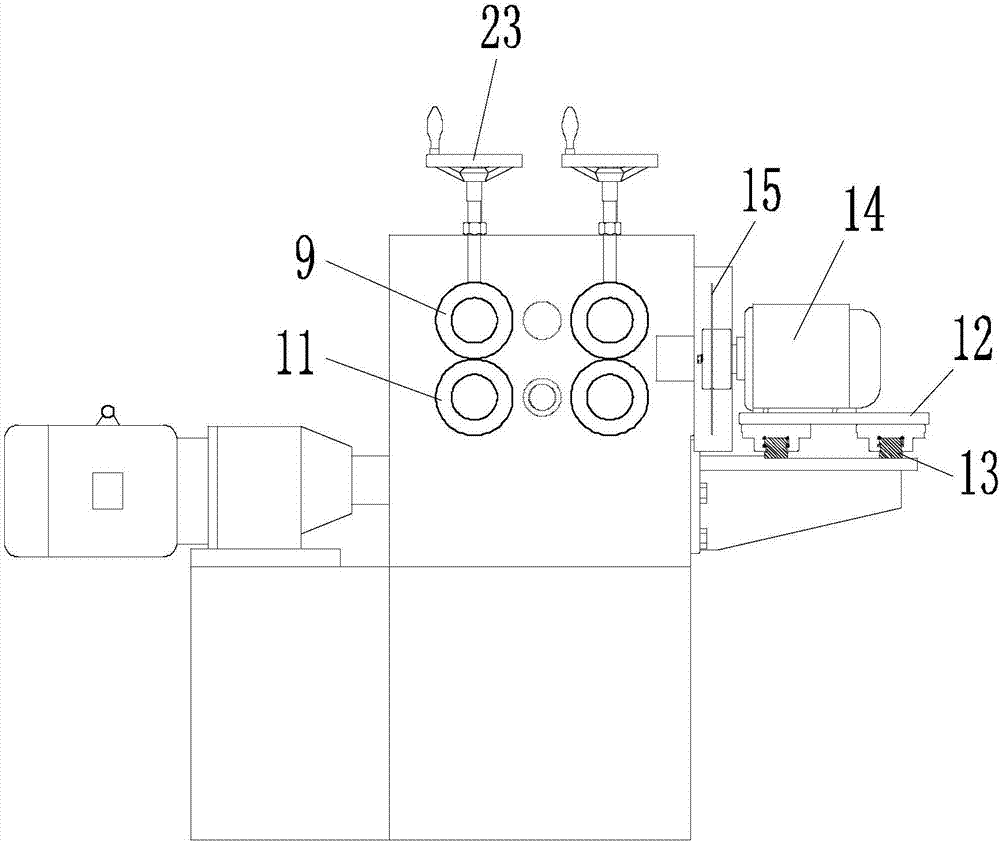

[0039] The main structure of this embodiment 2 is the same as that of embodiment 1, and the specific structure of the pressure roller set is changed in embodiment 2. Specifically, the copper buckle forming mechanism includes a power gear 7 and a pressure wheel set, and one or more sets of the pressure wheel sets can be set up and down along the feeding direction of the copper tube. The pinch wheel set includes a power connection gear 8 , a first pinch wheel 9 , a pinch wheel drive shaft 10 and a second pinch wheel 11 . The gear shaft of the power connection gear 8 is connected with the gear shaft of the second pinch wheel 11 through the pinch wheel transmission shaft 10. The first pinch wheel 9 is arranged above the second pinch wheel 11. The interval is the copper tube rolling interval. The first pinch roller 11 is set as a driven pinch roller, and is fixed on the frame through the pinch roller shaft. The gear shaft of the power gear 7 is connected with the first drive shaf...

Embodiment 3

[0042] The main structure of this embodiment 3 is the same as that of embodiment 1, and the specific structure of the pressure roller set has been changed in embodiment 3. Specifically, the copper buckle forming mechanism includes a power gear 7 and a pressure wheel set, and one or more sets of the pressure wheel sets can be set up and down along the feeding direction of the copper tube. The pinch wheel set includes a power connection gear 8 , a first pinch wheel 9 , a pinch wheel drive shaft 10 and a second pinch wheel 11 . The first pinch wheel 9 is arranged above the second pinch wheel 11, and there are two power connection gears 8 up and down. , the gear shaft of the power connection gear 8 located below is connected to the gear shaft of the second pinch wheel 9 through the pinch wheel transmission shaft 10, and the copper tube rolling section is between the first pinch wheel 9 and the second pinch wheel 11. The gear shaft of the power gear 7 is connected to the first dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com