Balanced suspension beam assembly with integrated air reservoir function

A crossbeam assembly and balanced suspension technology, which is applied to suspensions, elastic suspensions, cantilevers mounted on pivots, etc., can solve the problems of single function of the crossbeam, heavy assembly weight, and large number of parts, etc. Cost, production management cost reduction, and the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly described below in conjunction with the accompanying drawings.

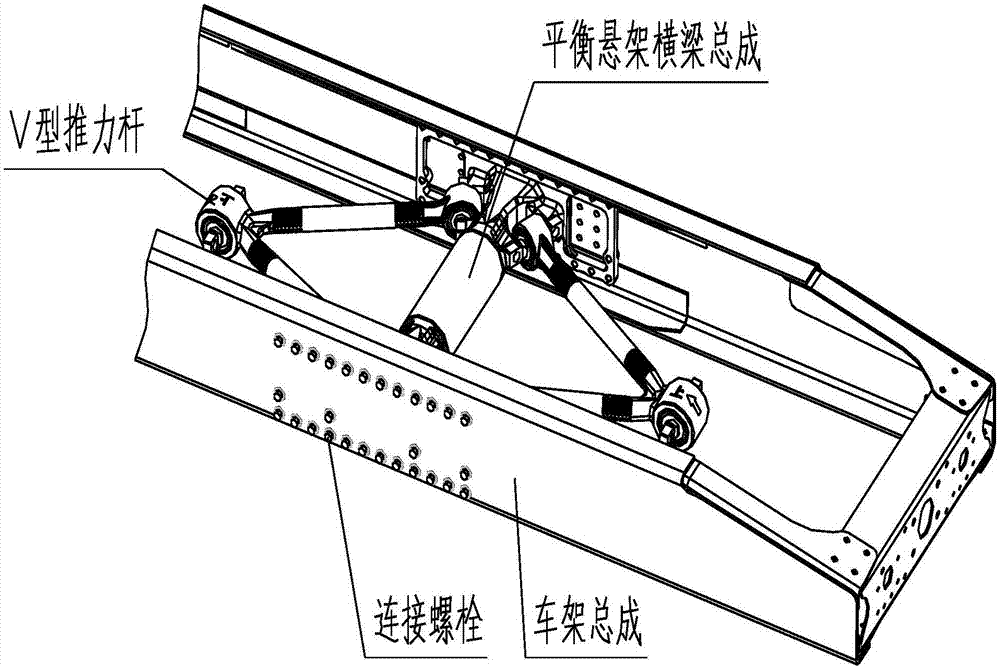

[0028] Such as figure 1 As shown, a balanced suspension crossbeam assembly integrating the function of the air reservoir of the present invention is arranged in the middle of the rear axle of a 6×4 tractor, and one end of the crossbeam connecting bracket 2 of the crossbeam assembly is respectively passed through 28 M14 The connecting bolts are connected to the longitudinal beam web plane, and the distribution of the connecting bolts is rectangular. There are 12 connecting bolts in the upper row, 4 connecting bolts in the middle row, and 12 connecting bolts in the lower row. The two V-shaped thrust rods are fixed on the beam connecting bracket of the beam assembly through two M20 connecting bolts.

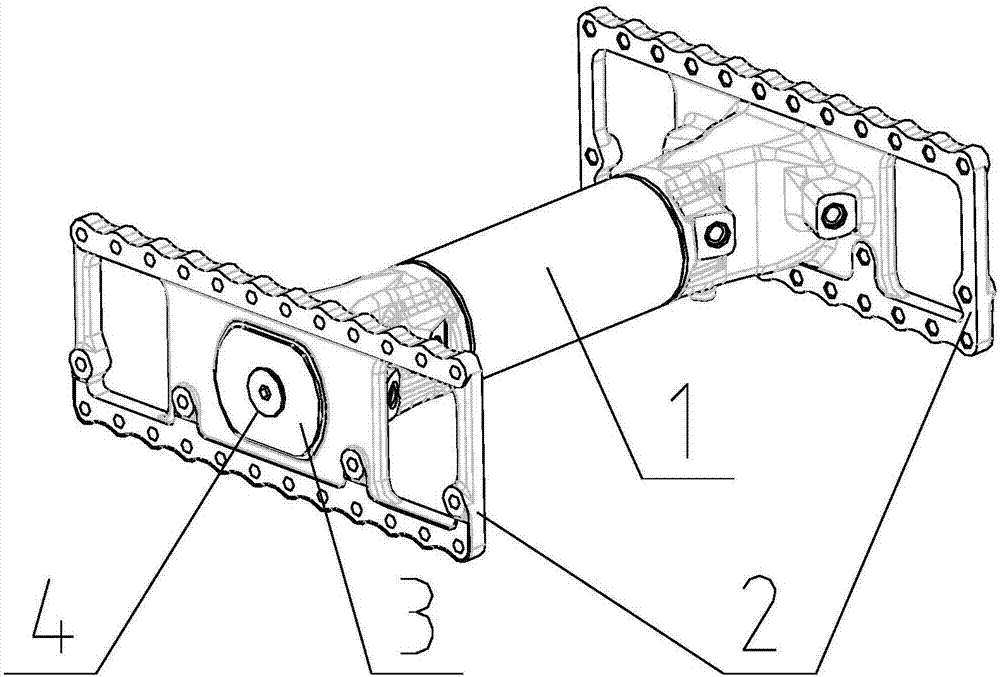

[0029] Such as Figure 2a As shown, the crossb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com