Automobile anti-collision beam structure based on bionic design

An anti-collision beam and automobile technology, applied in the direction of bumpers, etc., can solve the problems of unfavorable vehicle space layout and lightweight design, unfavorable vehicle safety performance, reducing the strength of the anti-collision beam, etc., so as to reduce the layout of connections and space, The effect of simplifying the installation process and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

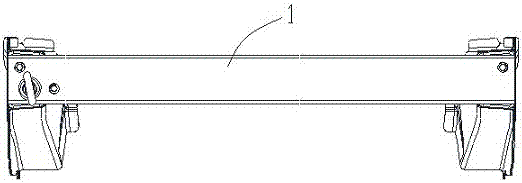

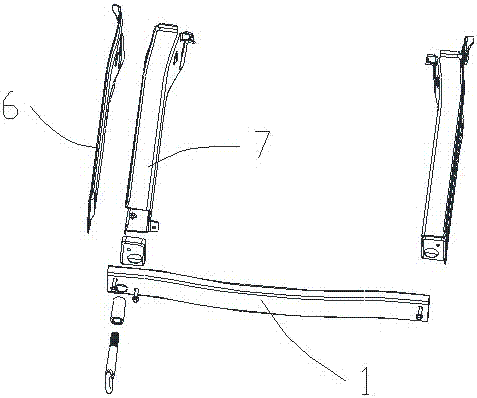

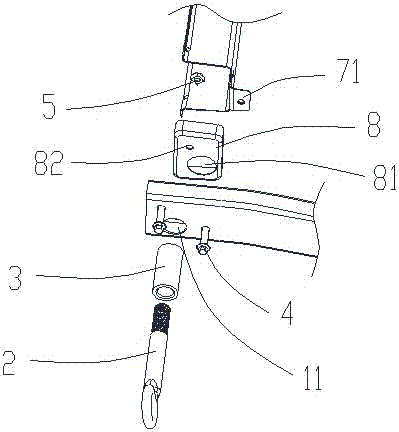

[0028] A kind of automobile anti-collision beam structure based on bionic design in this embodiment, see Figure 1 to Figure 3 , consisting of a beam body 1 and longitudinal beams located at two ends of the beam body 1 . The longitudinal beam includes a longitudinal beam inner panel 7 and a longitudinal beam outer panel 6 located outside the longitudinal beam inner panel 7 . Specifically, the end of the beam body 1 is provided with a sleeve welding hole 11, and the tow hook sleeve 3 is fixed in the sleeve welding hole 11, and the tow hook sleeve 3 is used to install the tow hook 2, and the sleeve welding holes 11 are two The sides are respectively provided with through screw holes, and the through screw holes are used to locate the connecting bolts 4 fixed to the beam body 1 and the longitudinal beam....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com