Multiple Bounce Flame Atomizer

A technology of multiple reflections and flame atoms, applied in material excitation analysis, thermal excitation analysis, etc., can solve the problem of low detection sensitivity of flame atomization method, and achieve the effect of improving measurement sensitivity, increasing luminous flux, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

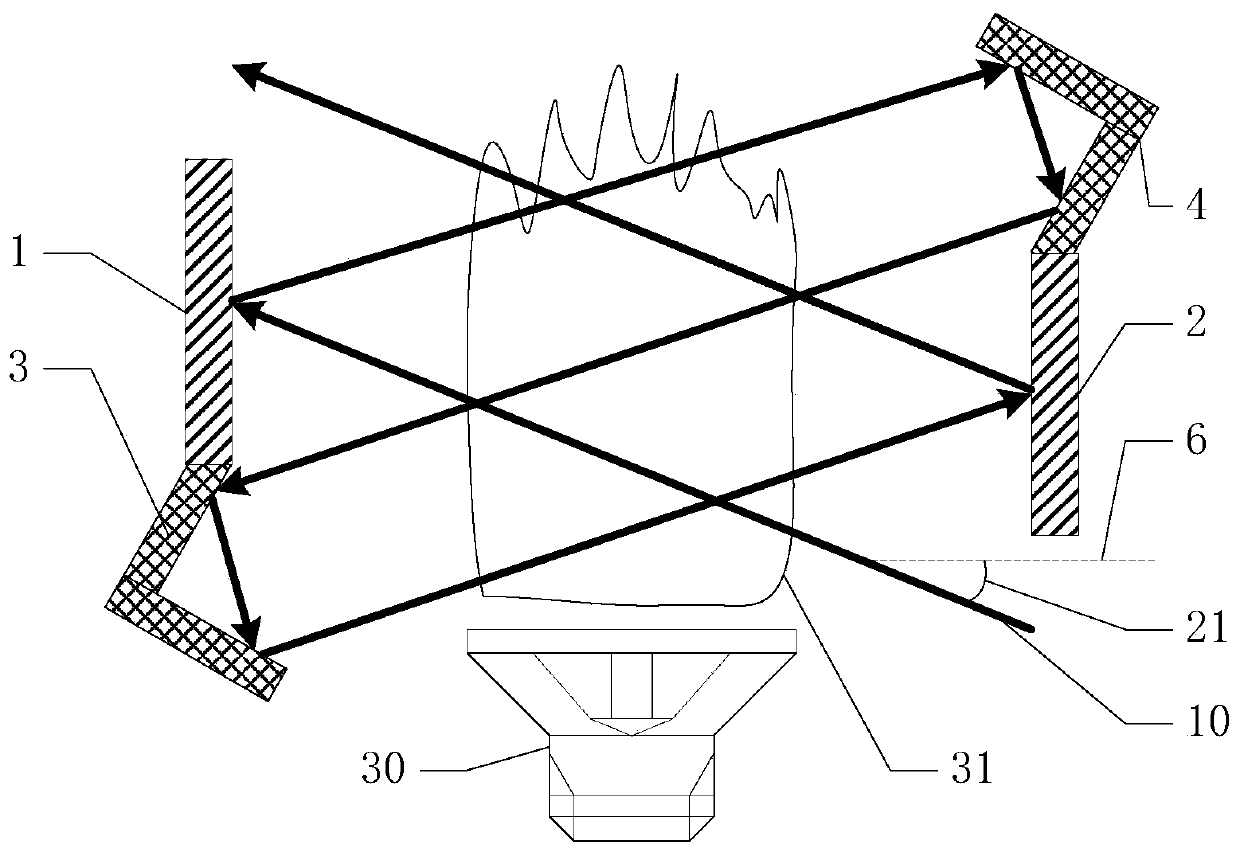

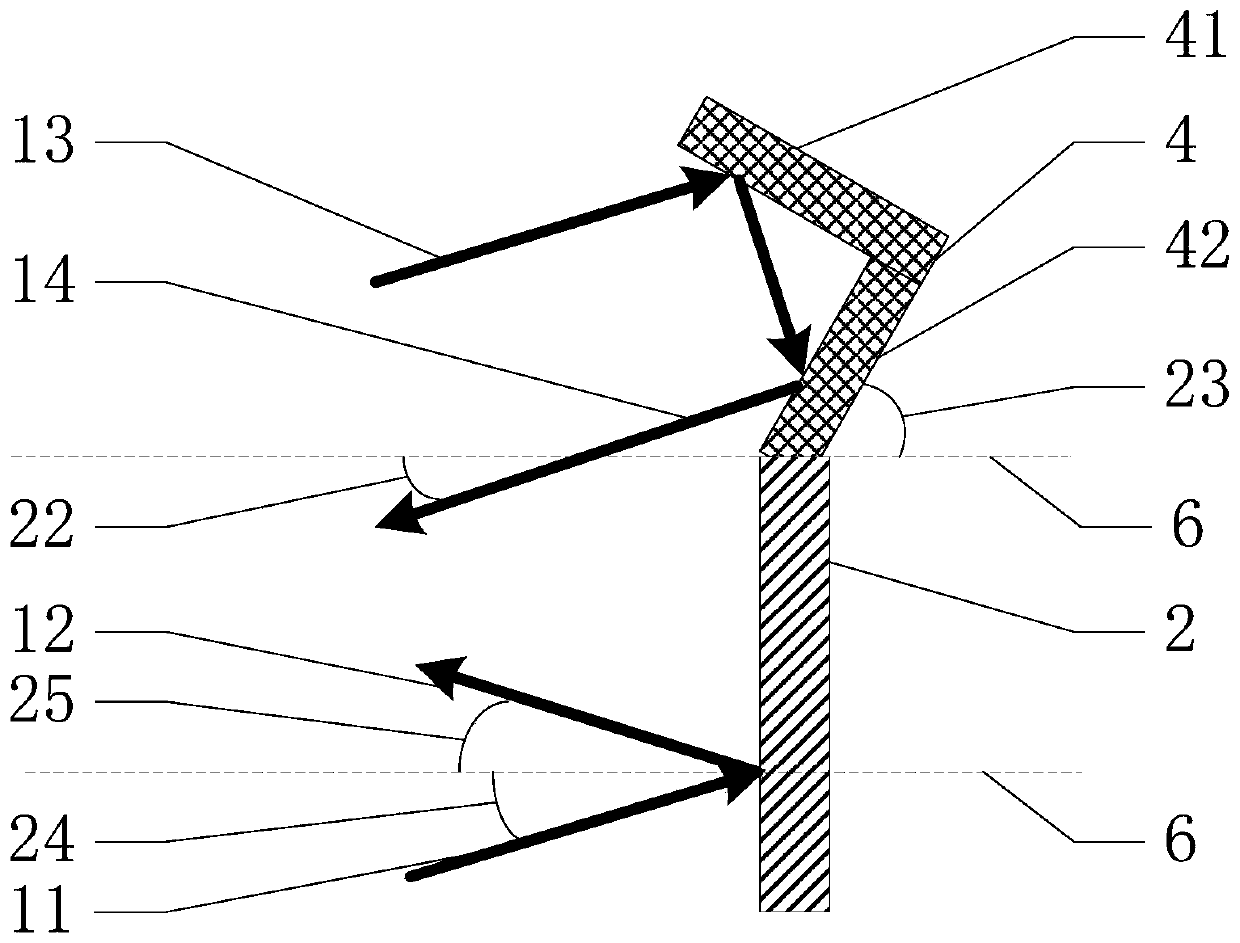

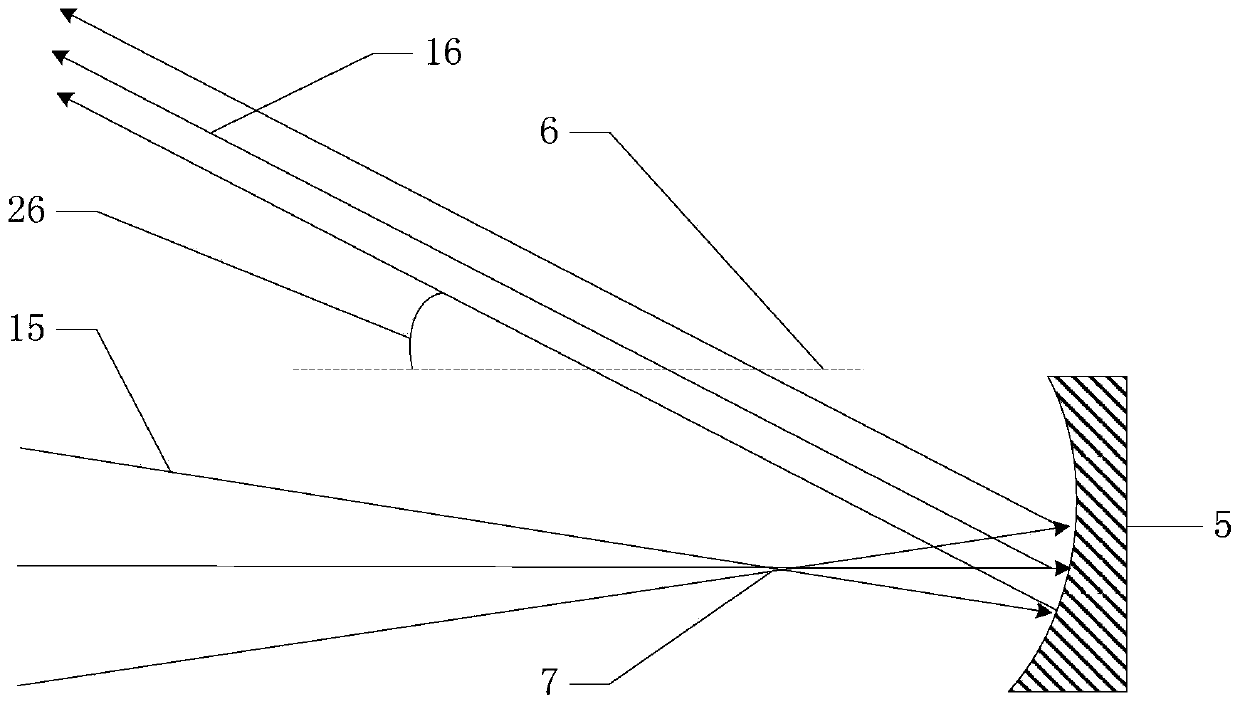

[0024] Such as figure 1 As shown, the multi-reflection flame atomizer includes a burner 30. After burning in the burner 30, a flame 31 is formed upward from the upper surface. The two symmetrical sides of the flame 31 are respectively provided with hook-shaped mirrors, and each hook-shaped mirror is respectively composed of Composed of a plane mirror and a right-angle reflector, the plane parallel to the upper surface of the burner 30 is used as the reference plane 6, the plane mirrors in each hook-shaped mirror surface are respectively perpendicular to the reference plane 6, and the reflection surfaces of the plane mirrors 1 and 2 on both sides of the flame are respectively facing the flame 31 and staggered relative to each other, wherein the upper end of the plane mirror 2 in the hook-shaped mirror surface on one side is connected with one end of the corresponding right-angle reflector 4, and the lower end of the plane mirror 1 in the hook-shaped mirror surface of the other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com