Insulating installation structure for installing cable tray in electrolysis workshop

A technology of cable tray and electrolysis workshop, applied in the direction of electrical components, etc., can solve problems such as introduction, and achieve reliable insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

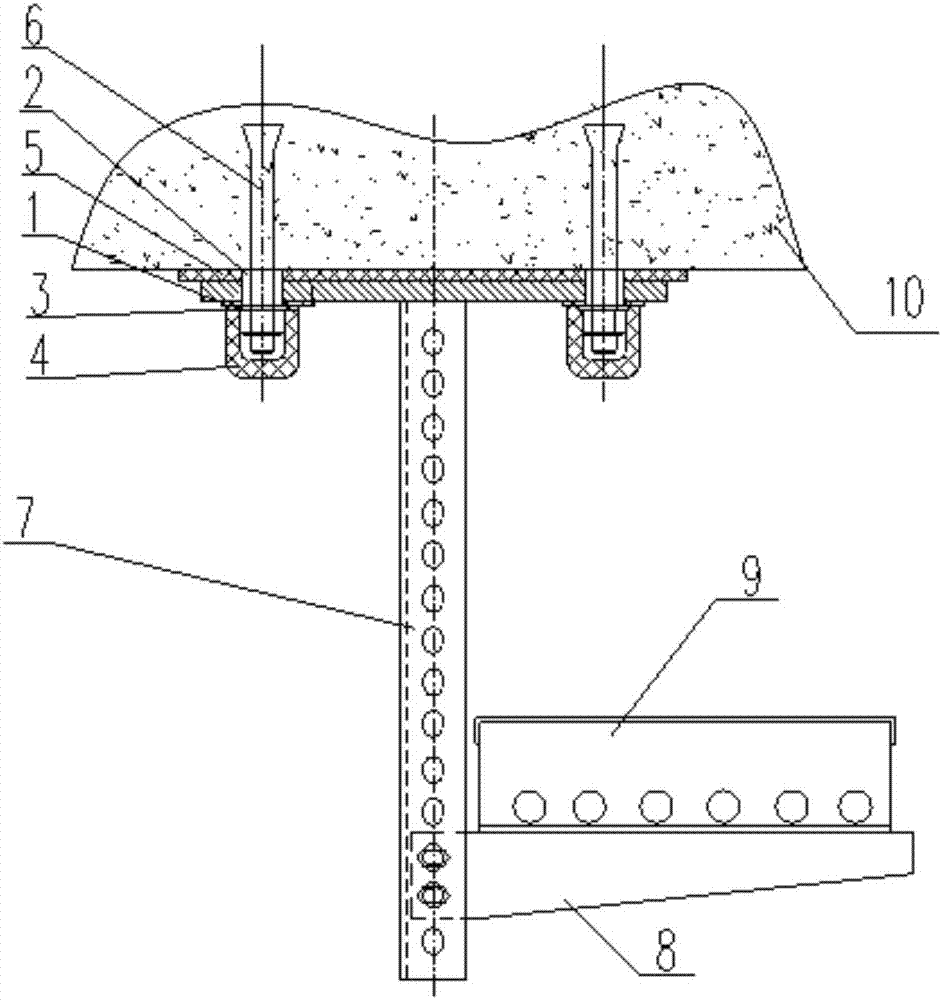

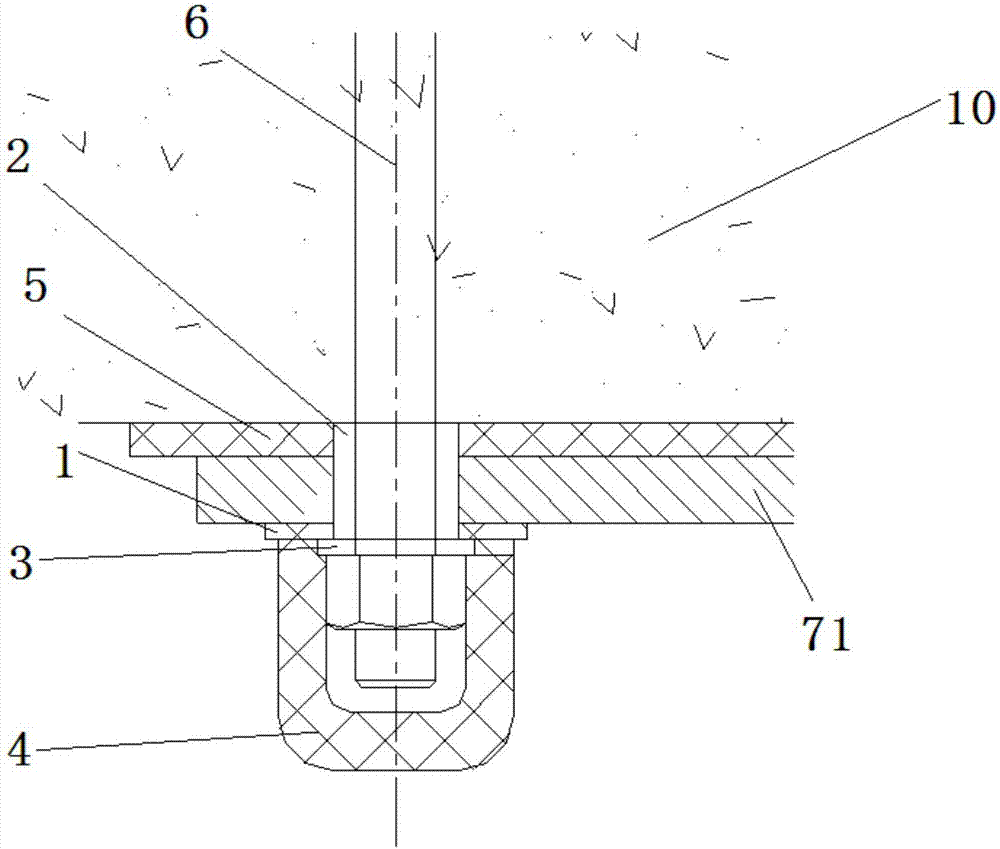

[0017] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 , figure 2 As shown, corresponding holes are set on the concrete wall or concrete floor 10 according to the bolt hole distance of the insulation board 5, and the depth and diameter of the holes match the anchor bolt 6; the insulation board 5 is arranged on the fixed surface, and the steel pillar 7 The base 71 of the base is in contact with the insulating plate 5, and the bolt holes of the insulating plate 5 correspond to the bolt holes of the base 71; the anchor bolt 6 is covered with an insulating bushing 2, and the anchor bolt 6 penetrates each bolt hole and is inserted into a concrete wall or a concrete floor 10 Middle; the insulating washer 1 and the flat washer 3 are set on the anchor bolt 6, and then fixed with nuts; the insulating sleeve 4 is set outside the nut and the flat washer 3.

[0018] A bridge support arm 8 is arranged on the steel pillar 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com