Plug-in type road ice and snow melting heat pipe and construction method thereof

A plug-in, heat pipe technology, applied in the field of road deicing and snow removal, can solve the problems of maintenance difficulties, reduce the maintenance cost of heat pipe surface, and heat pipes cannot be reused, and achieve the effect of efficient heat exchange and reliable heat preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

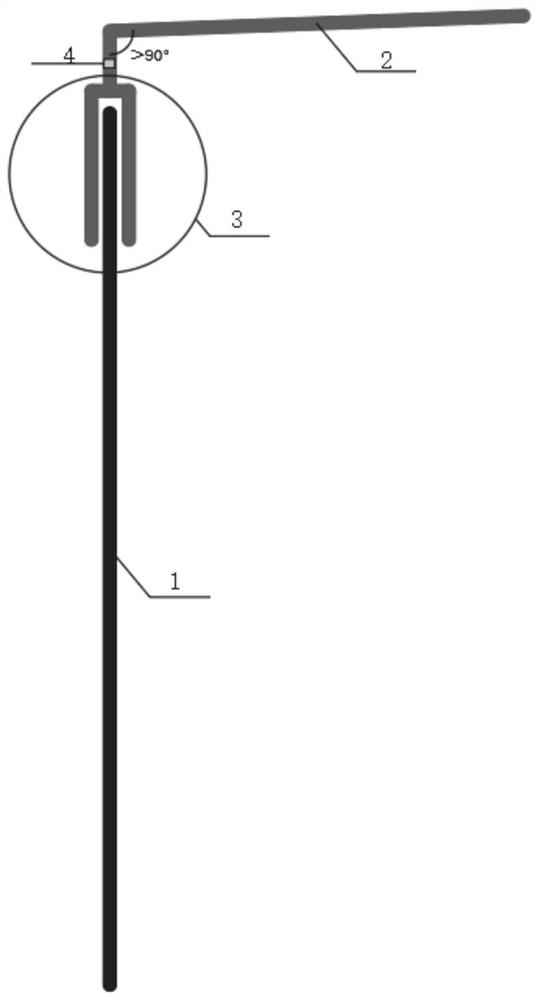

[0030] This embodiment provides a plug-in road ice and snow melting heat pipe, such as figure 1 As shown, it includes a lower heat pipe 1 , an upper heat pipe 2 and a plug-in heat exchange structure 3 , and the lower heat pipe 1 and upper heat pipe 2 are connected through the plug-in heat exchange structure 3 .

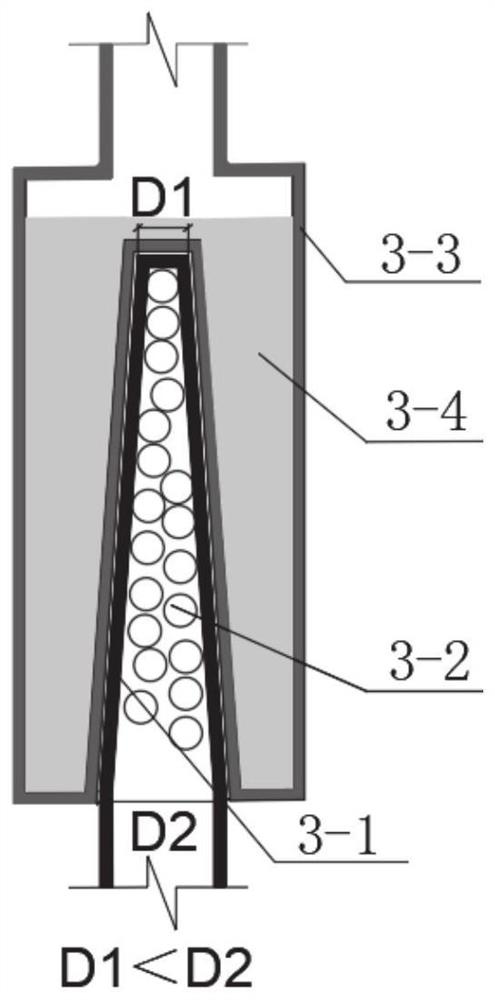

[0031] The lower heat pipe 1 is a complete heat pipe made of cold-drawn (rolled) seamless steel pipe, and its interior is a cavity. The lower heat pipe 1 is provided with a gaseous inorganic heat-conducting medium 3-2 inside, and the lower heat pipe 1 has a complete evaporation section, a conveying section and a condensation section.

[0032] The lower heat pipe 1 is divided into upper and lower parts, and its lower part is an evaporation section and a delivery section with a tubular structure of equal diameter, which are used to absorb and transport geothermal heat. The upper part of the lower heat pipe 1 has a condensing section with a circular platform structure, ...

Embodiment 2

[0042] This embodiment provides a construction method of a plug-in road ice and snow melting heat pipe. The main implementation process is: fixed-point setting out→drilling→lifting, installation, and fixing of the lower heat pipe 1→refilling and maintenance of cement mortar in the evaporation section of the lower heat pipe 1 →The upper heat pipe 2 is in place and the plug-in heat exchange structure 3 is connected →Adjust the telescopic adjustment device 4 of the conveying section of the upper heat pipe 4, and make the elevation and slope of the condensation section of the upper heat pipe 2 meet the design requirements →Fix the upper heat pipe 2 →Apply the lower heat pipe 1 Insulation of the transmission section, plug-in heat exchange structure 3 and upper heat pipe 2 transmission section → backfilling and maintenance of the condensation section of the upper heat pipe 2 → construction of the upper pavement structure.

[0043] In addition, in order to avoid causing troubles to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com