Fabricated RC structure beam-column connection joint convenient to maintain rapidly after earthquake

A beam-column connection and assembly technology, applied in protective buildings/shelters, earthquake resistance, building components, etc., can solve problems such as inability to perform rapid repairs, damage to beam-column joints, etc., and reduce the probability of serious structural damage , high degree of assembly, and good energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

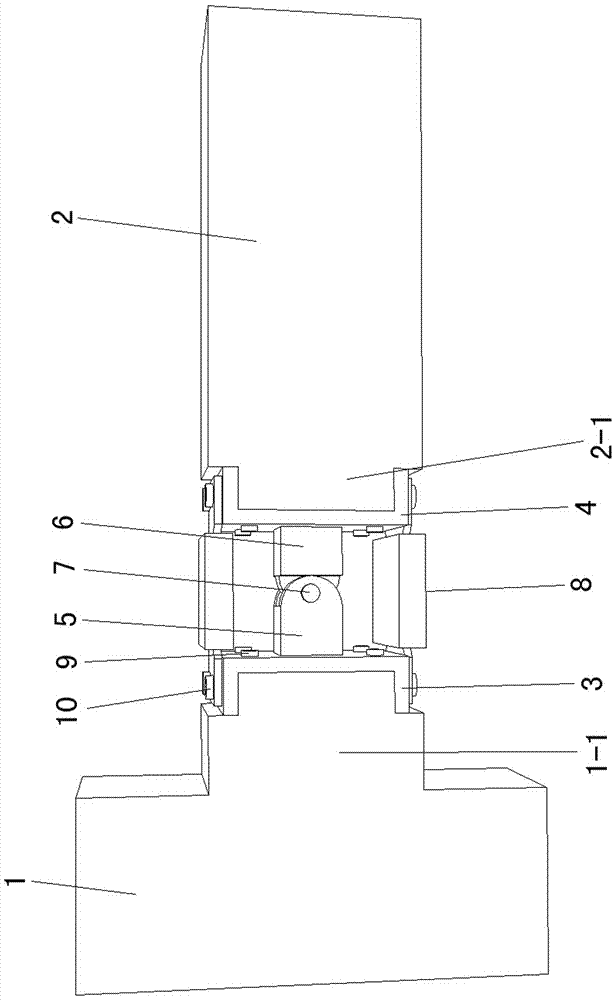

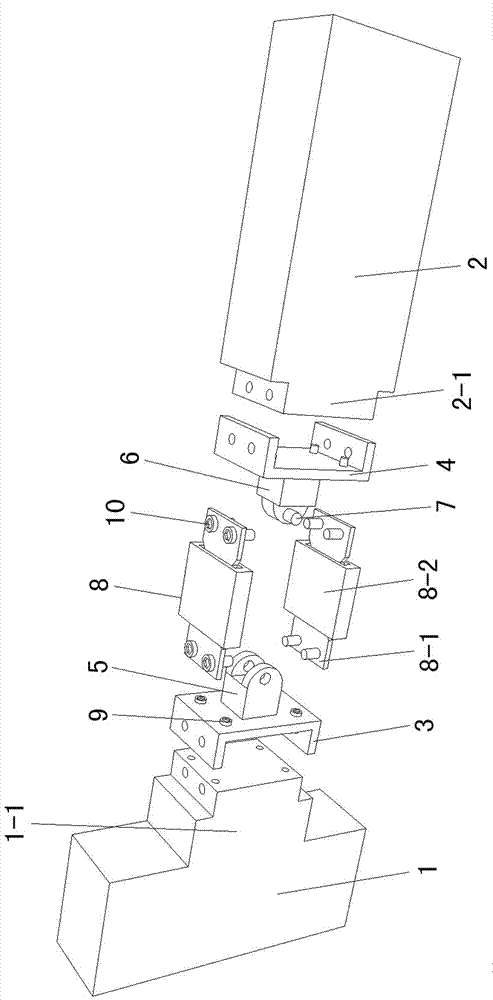

[0011] Specific implementation mode one: as Figure 1~Figure 3 As shown, the present invention discloses a prefabricated RC structure beam-column connection node that is convenient for rapid repair after an earthquake, including a pre-embedded steel part 1 for a column node, a pre-embedded steel part 2 for a beam node, a positioning steel plate 3 for a column end, and a beam end Positioning steel plate 4, column end ear plate 5, beam end ear plate 6, and two anti-buckling energy-dissipating components 8, the middle position of the column node pre-embedded steel part 1 is provided with a connecting protrusion 1-1, so The outer end of the connecting protrusion 1-1 is made into a cuboid, and the middle position of the end surface of the embedded steel part 2 of the beam node is provided with a connecting protrusion 2-1, and the shape of the connecting protrusion 2-1 is It is a cuboid, the column end positioning steel plate 3 and the beam end positioning steel plate 4 are all U-sh...

specific Embodiment approach 2

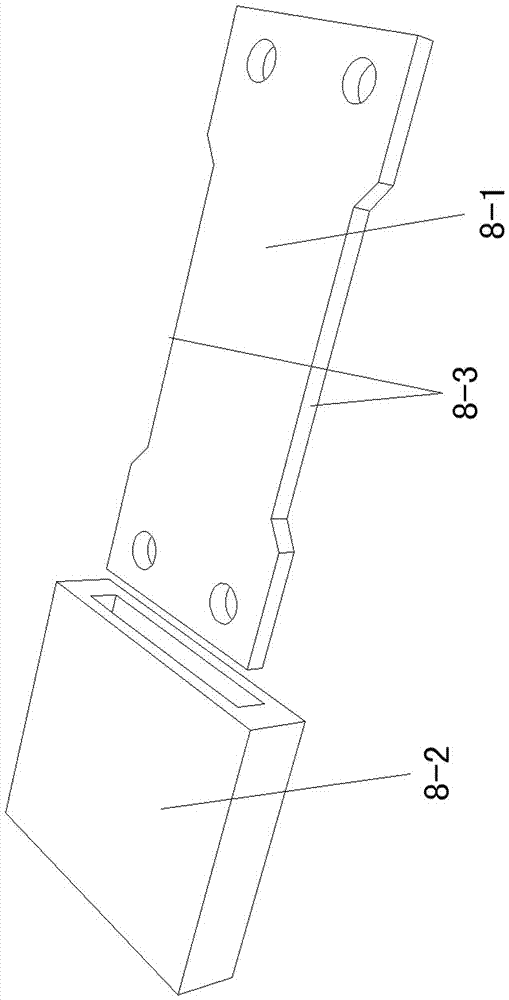

[0012] Specific implementation mode two: as figure 2 As shown, this embodiment is a further description of specific embodiment 1. The two anti-buckling energy-dissipating members 8 are both composed of a core plate 8-1 and a steel sleeve 8-2, and the two steel sleeves 8-2 The sleeves 8-2 are respectively slid and fitted in the middle of the corresponding core plates 8-1, and one end of the two core plates 8-1 respectively passes through the side of the corresponding column end positioning steel plate 3 and the side of the connecting protrusion 1-1. Two shear bolts 10 are detachably fixedly connected, and the other ends of the two core plates 8-1 are respectively connected to the side of the corresponding beam end positioning steel plate 4 and the side of the connecting protrusion 2-1 through two shear bolts 10. .

specific Embodiment approach 3

[0013] Specific implementation mode three: as image 3 As shown, this embodiment is a further description of the second specific embodiment. The two core plates 8-1 are rectangular steel plates, and the middle positions on both sides of each core plate 8-1 are symmetrically provided with grooves 8 -3, the two steel sleeves 8-2 are rectangular cylinders.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com