Combined type low-noise hundred-class laminar flow system

A 100-level laminar flow and low noise technology, applied in the field of combined low-noise 100-level laminar flow system, can solve problems such as affecting medical staff, mental fatigue, secondary pollution, etc., to reduce secondary infection, reduce self-cleaning time, The effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

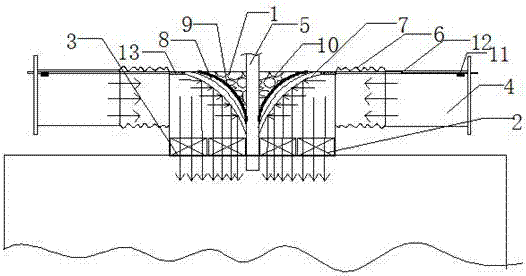

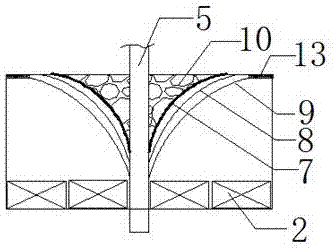

[0029] Such as Figure 1-5 As shown in , a combined low-noise 100-level laminar flow system includes a mixed flow box 1, the air supply duct 4 for air supply is connected to both sides of the mixed flow box 1, and the middle part of the mixed flow box 1 is provided with a vertically penetrating mixed flow box 1 The shadowless lamp sleeve 5, the bottom of the mixed flow box 1 is provided with a flow equalization layer 3 that can evenly distribute the air flow, and a hose 6 with the same diameter as the air supply pipe 4 is provided between the air supply pipe 4 and the mixed flow box 1. A small cylinder 11 is installed horizontally on the top of the air duct 4, and a horizontal guide rail 13 is installed on the top of the mixed flow box 1 near the hose 6;

[0030] On both sides of the shadowless lamp sleeve 5 in the mixed flow box 1, with the top surface and the vertical surfaces on both sides of the shadowless lamp sleeve 5 as the right-angle sandwiching surface, there are sou...

Embodiment 2

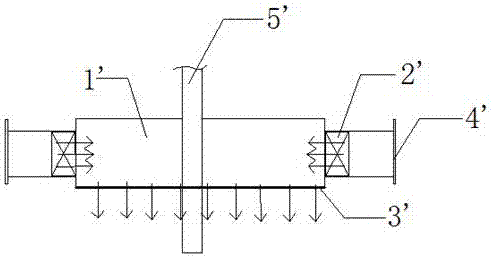

[0041] After removing the inner microporous sound-absorbing panel on the basis of Example 1, it was 45 decibels in a steady state, and the time to reach 50 decibels was compared with that of the prior art. figure 1 The middle device shortens the time by about 20%.

Embodiment 3

[0043] On the basis of Example 1, after the sound-absorbing filling material and the flexible mesh layer are removed, it is 46 decibels in a steady state, and the time to reach 50 decibels is compared with that of the prior art. figure 1 The middle device shortens the time by about 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com