Unequal-distance stepped linear Fresnel solar condenser

A technology of solar concentrators and linear Fresnel, applied in the field of solar concentrators, can solve the problems of increasing production difficulty and installation time, affecting equipment stability, and low system utilization, achieving good wind resistance and reducing design Difficulty, the effect of good heat collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The above content is only to illustrate the technical idea of the present invention, and cannot limit the protection scope of the present invention. Any changes made on the basis of the technical solution according to the technical idea proposed in the present invention shall be regarded as the protection scope of the present invention; The technology not involved in the invention can be realized by the existing technology.

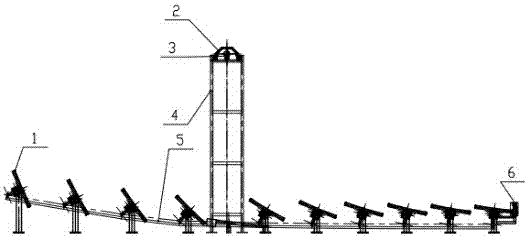

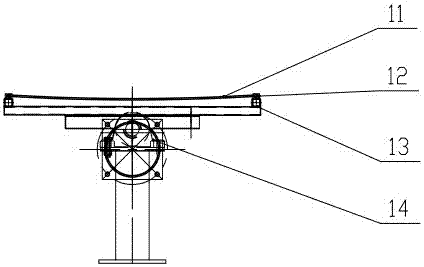

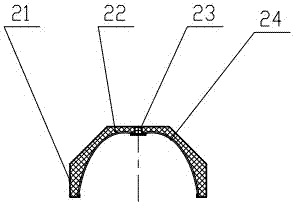

[0023] A stepped linear Fresnel solar concentrator with unequal distances is characterized in that it includes a primary micro-arc reflector group 1, and each reflector 11 is installed on a primary mirror installation steel structure 13, from high to low Arranged in order with unequal spacing. Considering the problem of shadow and occlusion between the mirror fields, the east-west axis arrangement is adopted, the south is low and the north is high, and the distance between columns increases from south to north. The arrangement maximizes the use o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com