Circulation pretreatment vibration blanking drying device for meat and bone meal feed production

A drying device and pretreatment technology, which is applied in the directions of drying gas arrangement, drying solid materials, drying, etc., can solve the problems of long processing time and limit processing efficiency, and achieve uniform distribution of hot air, improve drying efficiency, and increase drying effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

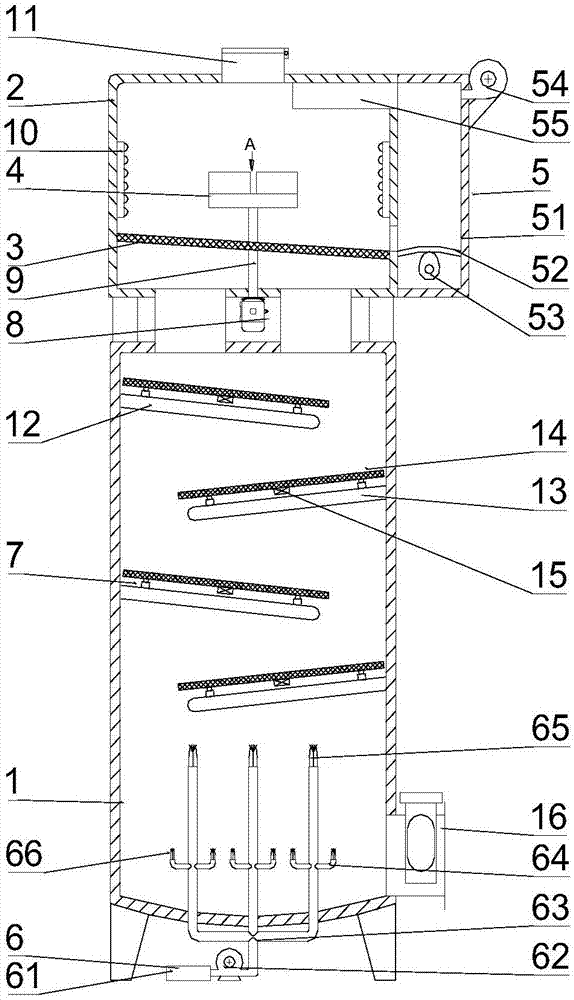

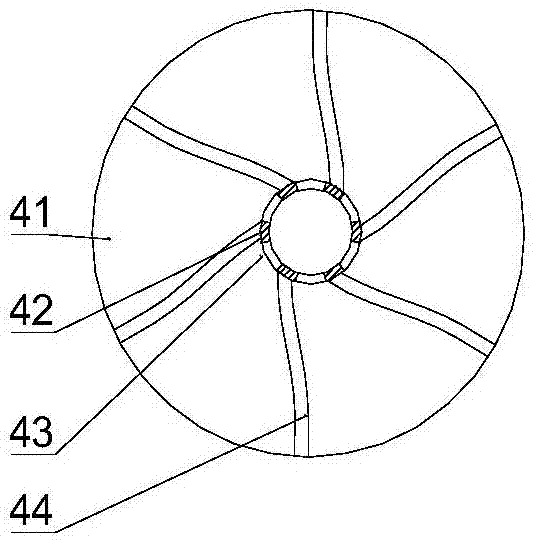

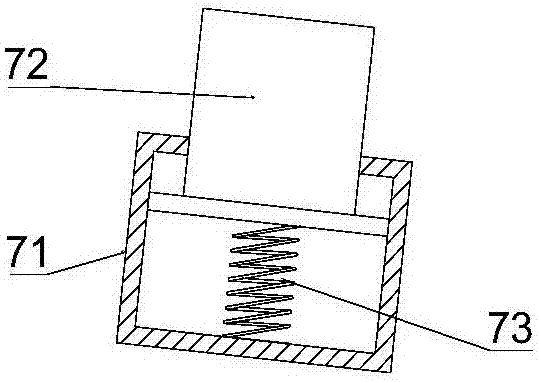

[0018] see Figure 1-3 , a circulation pretreatment vibration blanking type drying device for meat and bone meal feed production, comprising a pretreatment box 2, a drying box 1, a centrifugal throwing device 4, a circulating feeding device 5, an inclined screen 3, a vibrating feed plate 14 and The hot air device 6, the inner lower side of the pretreatment box 2 is fixedly connected with an inclined screen 3, and the inclined screen 3 is in an inclined shape with a high left and a low right, a motor 8 is installed at the bottom of the pretreatment box 2, and the pretreatment The inside of the box 2 is provided with a rotating column 9 that can move through the inclined screen 3, the output end of the motor 8 is fixedly connected with the bottom end of the rotating column 9, and the top of the rotating column 9 is fixedly equipped with a centrifugal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com