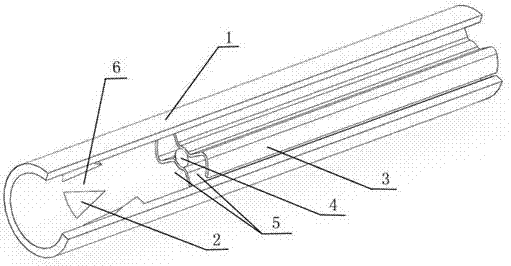

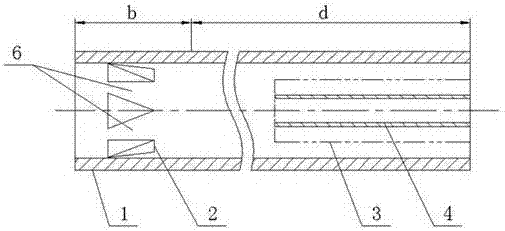

Internally finned tube heat exchanger with micro wedge structures

A technology of inner fins and heat exchangers, which is applied in the field of inner finned tube heat exchangers, can solve the problems of shortening and affecting the heat dissipation effect, and achieve the effects of saving resources, improving heat exchange efficiency, and shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

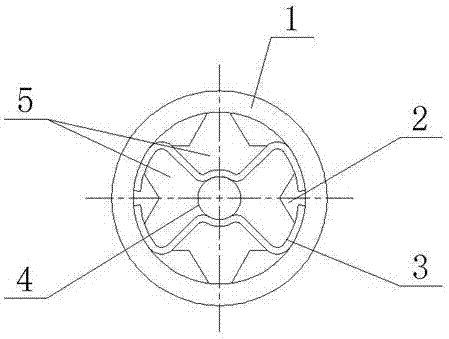

[0028] The number of micro-wedges 2 is 6; the micro-wedges 2 are concentrically and evenly distributed on the inner wall of the heat exchange shell 1; due to the obstruction of the structure of the micro-wedges 2, eddy currents are formed at the micro-wedges 2, and a part of the heat exchange The heated medium flows out from the fluid channel 6, and the other part is blocked by the micro-wedge 2 to flow back, and the heat transfer is strengthened again. Repeatedly, the heat exchange efficiency of the heat exchanger is improved.

[0029] exist Image 6 , the second embodiment:

[0030] The number of the micro-wedges 2 is 6; the micro-wedges 2 are staggered and evenly distributed in the circumferential direction of the inner wall of the heat exchange shell 1; heat transfer efficiency of the heat exchanger.

[0031] exist Figure 7 In the third embodiment:

[0032] The number of micro-wedges 2 is 6; the micro-wedges 2 are symmetrically and evenly distributed along the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com