Rolling bearing performance degradation evaluation method based on admm and sparse combined learning

A rolling bearing and combined learning technology, which can be used in mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., and can solve problems such as time-consuming search for atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

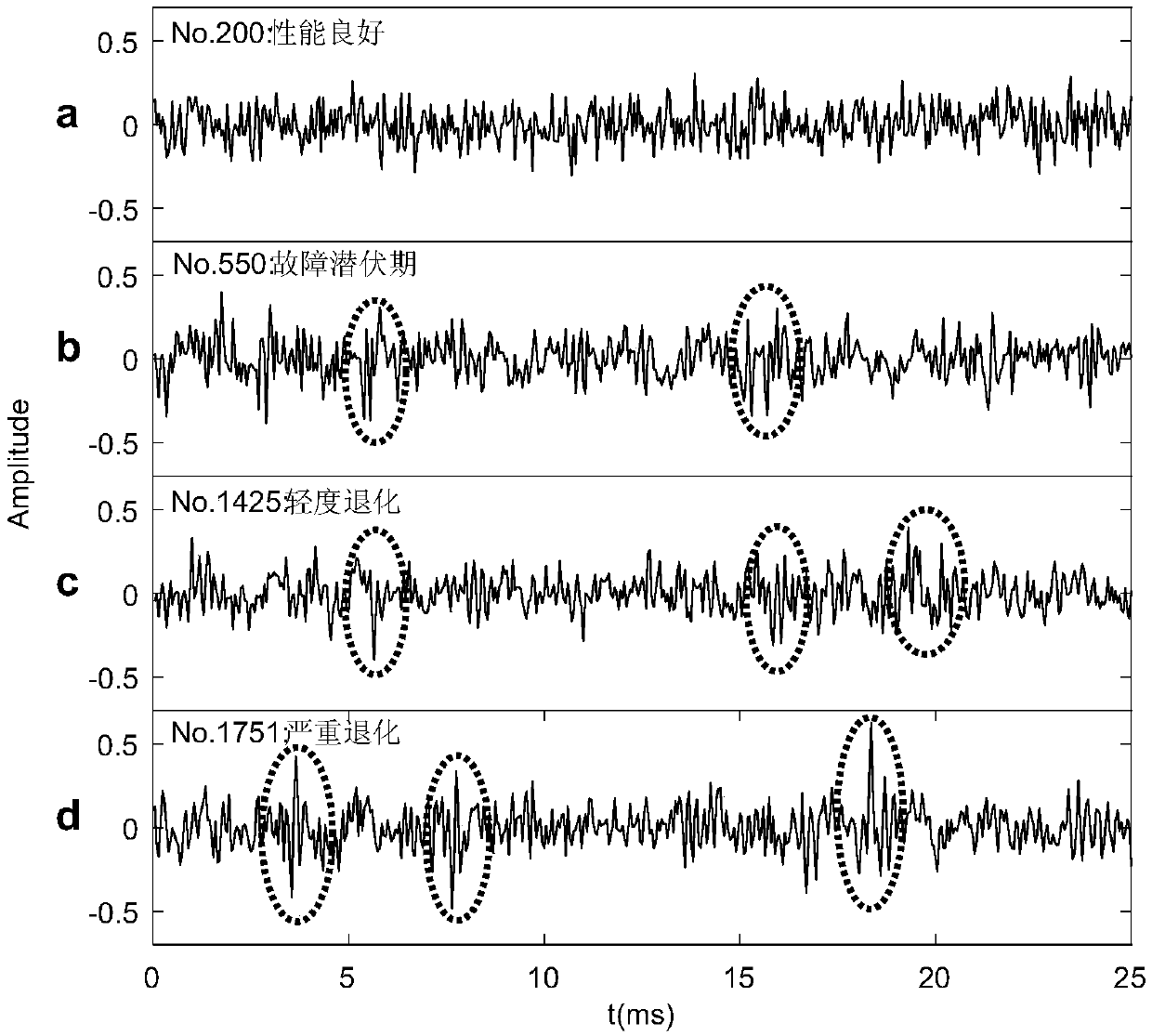

[0065] The data used in this embodiment comes from the National Aeronautics and Space Administration (NASA) pre-diagnosis database, provided by the research group of Professor Jay Lee of the Intelligent Maintenance System Center (IMS) of the University of Cincinnati.

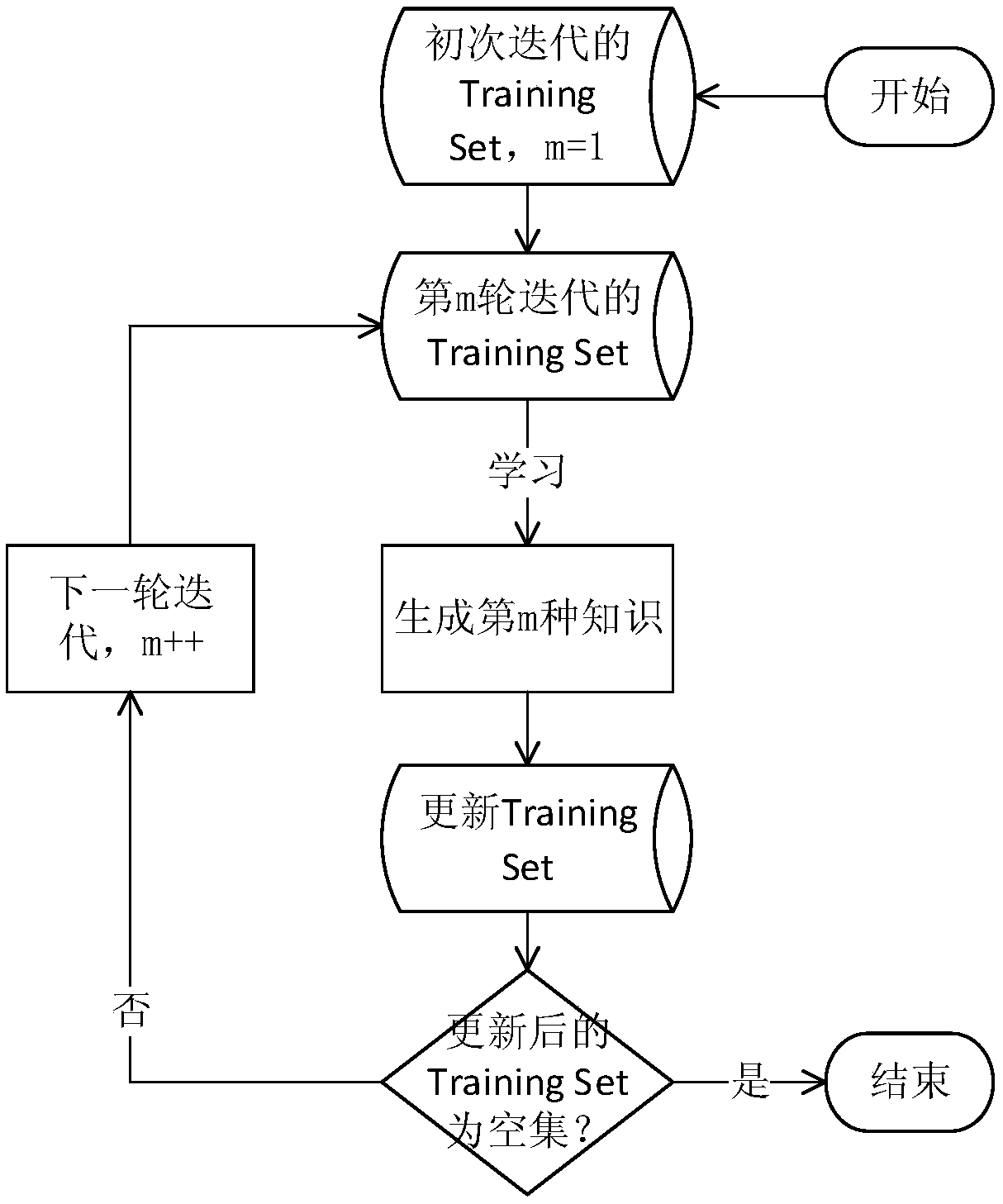

[0066] In this embodiment, we only use the vibration data of bearing 3 of experiment No.1 in the IMS database. At the beginning of the experiment, it was assumed that the performance of the rolling bearing was good. We assume that the data of the first ten days of the experiment were collected when the bearing performance was good (note: the experiment time was from 2003-10-22 to 2003-10-31, a total of 368 sets of data), and the data of the first ten days were normalized One-time preprocessing, and then form the Training Set of the first iteration. The rest of the data were normalized and preprocessed according to the Training Set method, and then formed the Test Set (Note: The experiment time was from 2003-11-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap