Method for measuring concrete pore structure and dedicated forming device

A technology for forming devices and pore structures, applied in measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve the problems of inaccurate concrete pore structure, limited application of highly toxic substances, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention is further invented below in conjunction with the drawings.

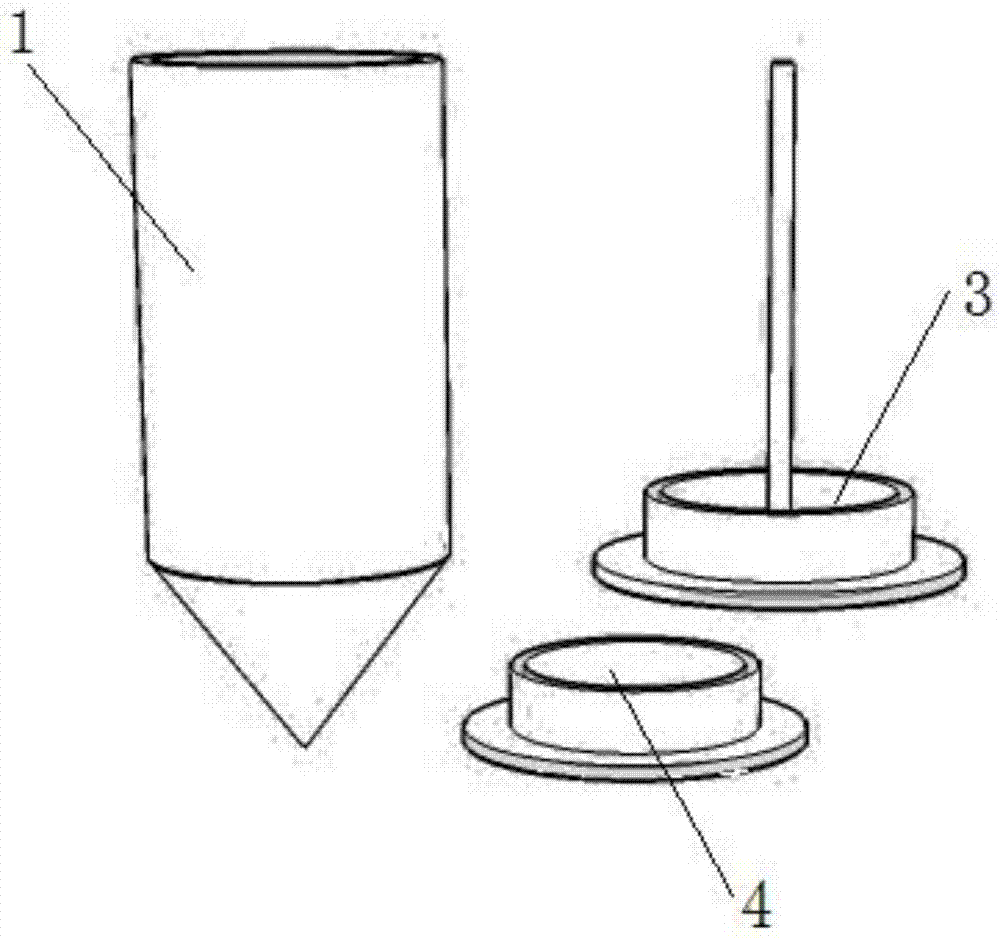

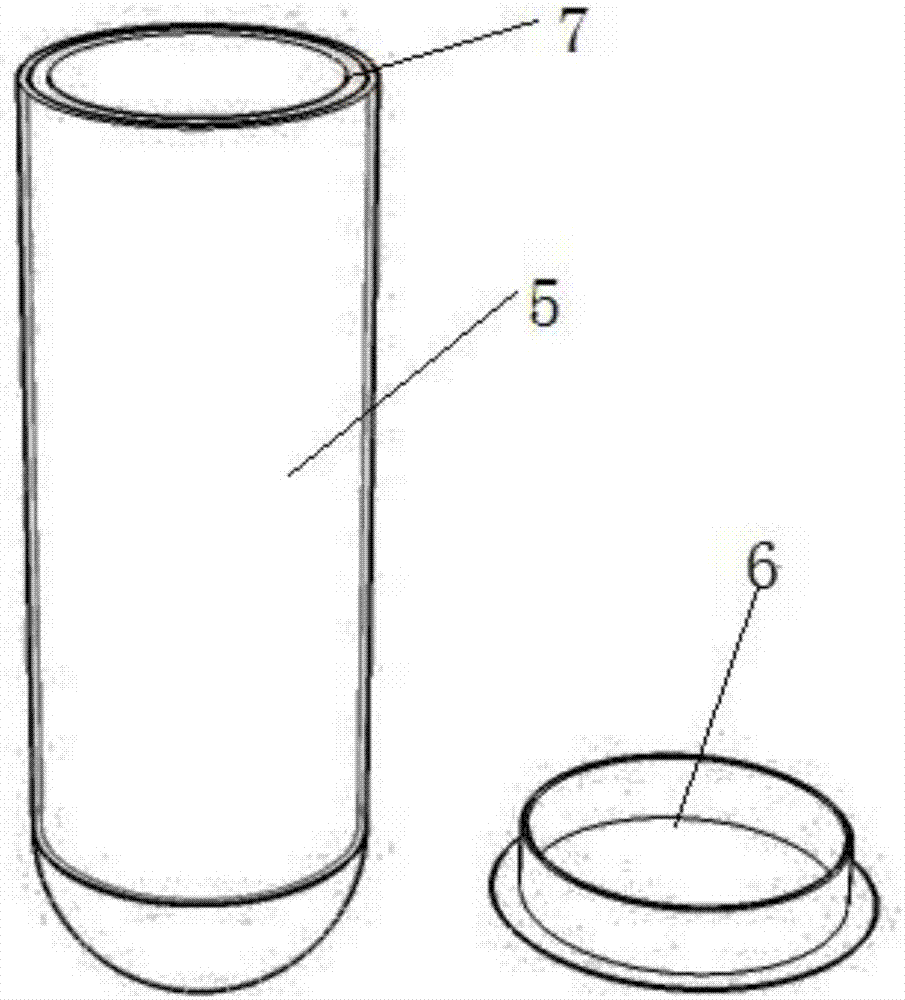

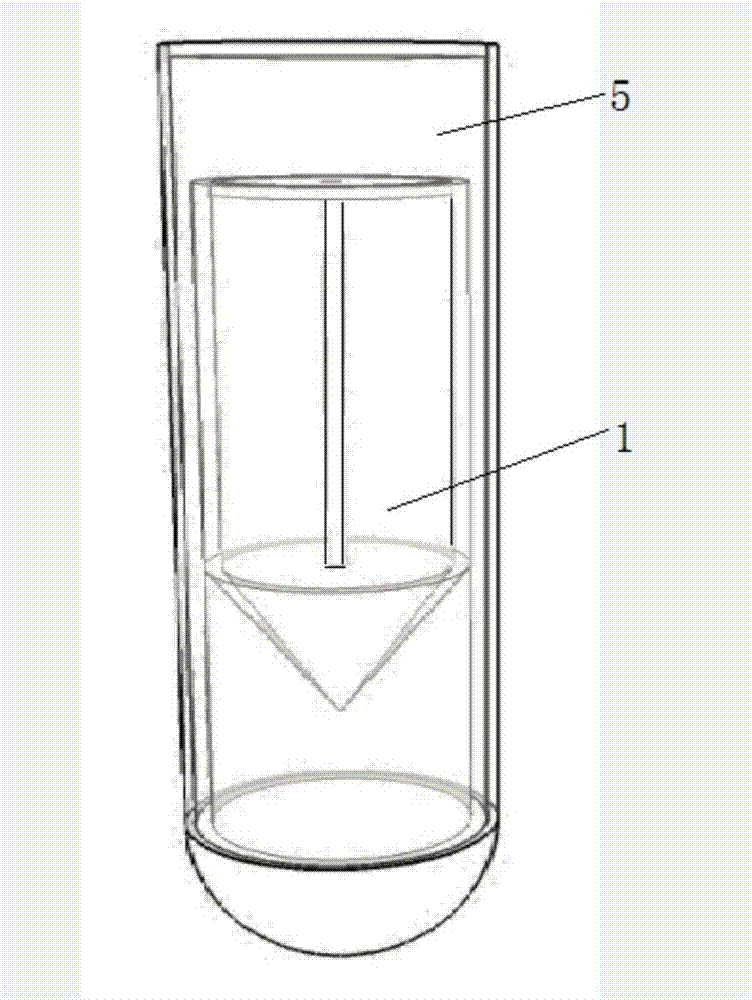

[0021] Such as Figure 1-4 As shown, the pore structure of P·I52.5 Portland cement is used for the determination, the Portland cement is mixed with 1000g cement and 600g into the slurry to be tested, and the slurry to be tested is first injected into the molding device. In the centrifugal tube 1 of the forming device, cover the centrifugal tube plug 3 with a rod. After the slurry has solidified and hardened, remove the centrifugal tube plug 3 with a rod and cover the centrifuge tube cap 4 for 14 days of maintenance. After curing, the centrifuge tube cap 4 Take it down, terminate the hydration with alcohol, and then put it into a vacuum drying box for drying. The drying time and temperature are set according to the slurry to be tested. The drying process of the Portland cement to be tested is set to 65 Drying for 3 days under the condition of ℃, the sample with the cavity is obtained; then the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com