Enterprise hidden danger management method and its management system, electronic equipment and storage medium

A management method and enterprise technology, applied in data processing applications, special data processing applications, instruments, etc., can solve problems such as unsafe conditions and unsafe factors in the environment, so as to reduce safety production accidents, improve efficiency, prevent and safety Effects of Production Accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

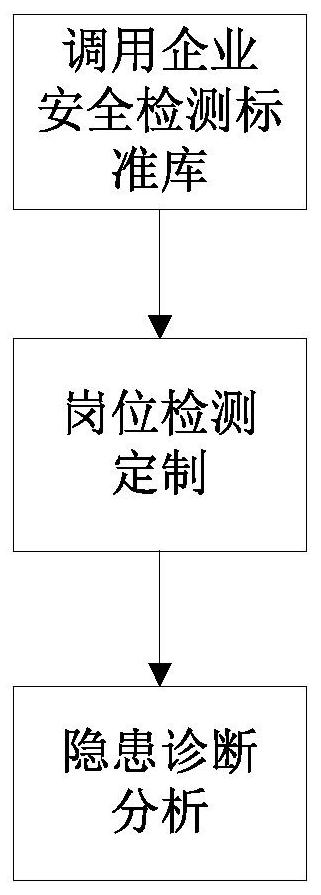

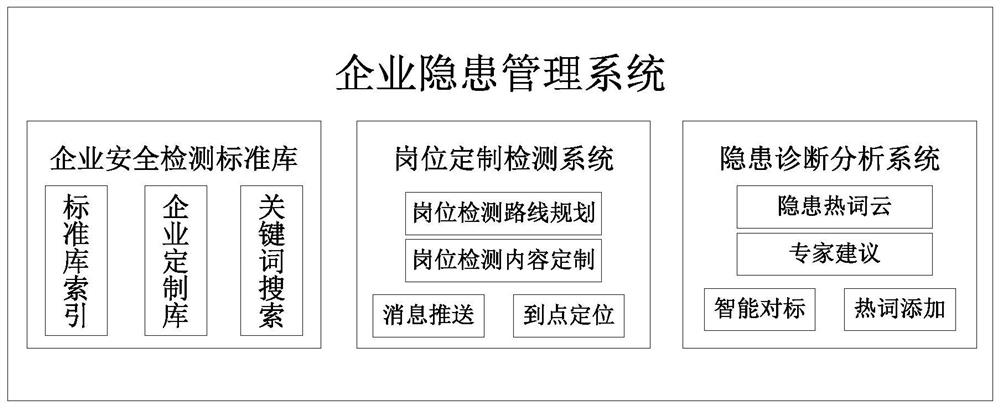

[0047] Enterprise hazard management methods, such as figure 1 shown, including the following steps:

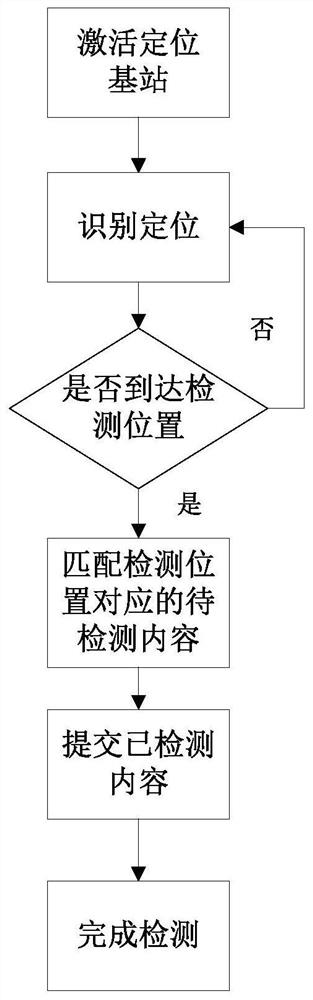

[0048] Call the enterprise security testing standard library, the enterprise security testing standard library is used to store the enterprise security testing information, formulate the content to be tested according to the enterprise security testing standard library; generally, the enterprise security testing standard library stores the enterprise security testing information Information, formulate the content to be detected and the route to be detected according to the enterprise security detection standard library, wherein the content to be detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com