Superhigh-strength steel core and high-strength heat-resistant aluminum-alloy conductor used for smart power grids and preparation method thereof

An aluminum alloy wire, ultra-high-strength technology, applied in the direction of metal/alloy conductors, cable/conductor manufacturing, conductors, etc., can solve problems such as easy generation of waste wire, increase manufacturing costs, increase cost investment and risks, and achieve improved Production efficiency, improved elongation, and large draw-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

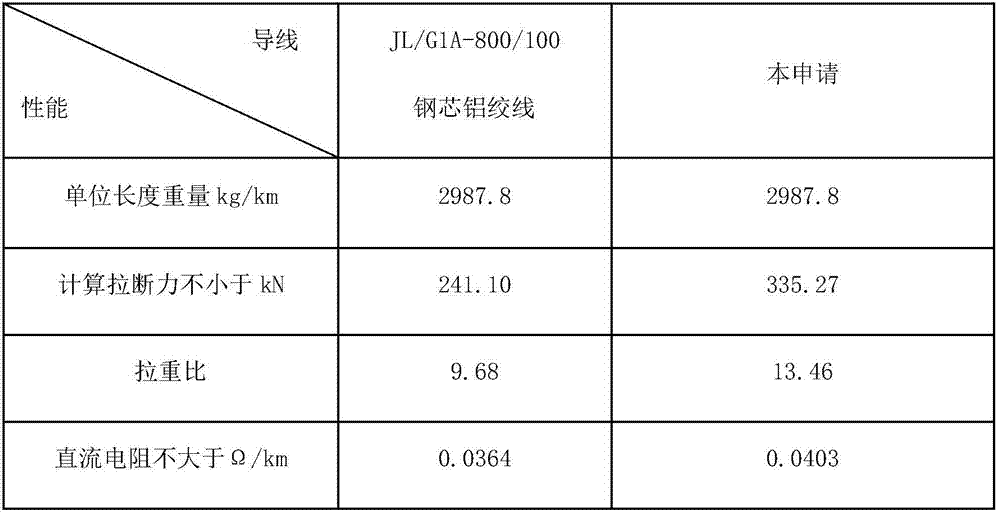

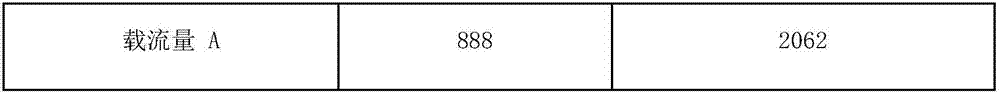

[0021] A high-strength heat-resistant aluminum alloy wire with an ultra-high-strength steel core for smart grids, consisting of 54 high-strength heat-resistant aluminum alloy wires with a single-filament diameter of 4.33mm and 19 ultra-high-strength steel cores with a single-filament diameter of 2.60mm concentrically stranded The direct current resistance of the wire at 20°C is ≤0.0403Ω / km, and the entire tensile force is ≥335.27kN; the conductor resistivity of the high-strength heat-resistant aluminum alloy wire at 20°C is ≤0.031065Ω·mm 2 / m, minimum tensile strength 228-238MPa, elongation 1.8-2.2%, electrical conductivity ≥ 55% IACS, after high temperature treatment at 230°C for 1 hour, the residual rate of tensile strength ≥ 90%; the ultra-high-strength steel Core monofilament tensile strength ≥ 1870MPa, 1% elongation stress ≥ 1550MPa, elongation ≥ 2.0%.

[0022] Preparation method of ultra-high-strength steel core high-strength heat-resistant aluminum alloy wire for smart ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Dc resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap