Battery charging method, apparatus and equipment

A battery charging and battery technology, applied to battery circuit devices, secondary battery charging/discharging, circuit devices, etc., can solve the problems of shortening battery life, battery overcharging, and charging efficiency reduction, so as to optimize service life and avoid The risk of overcharging and the effect of improving charging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

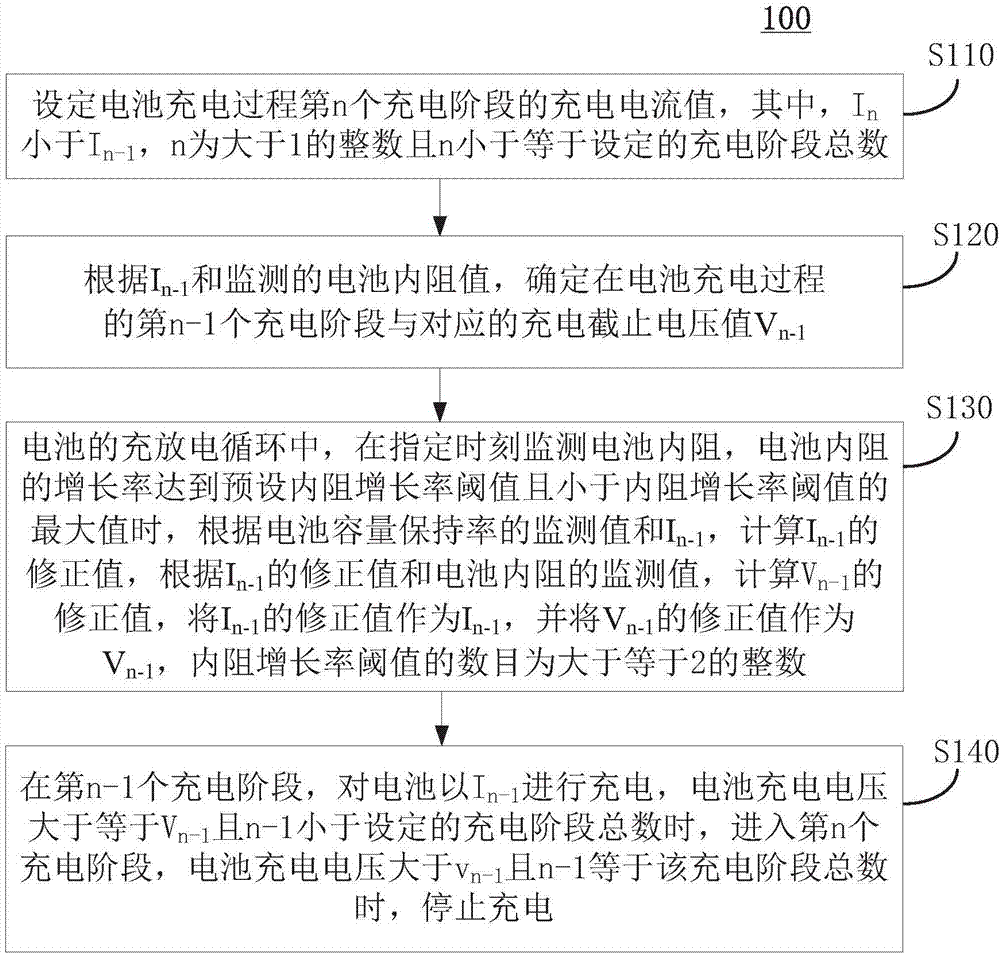

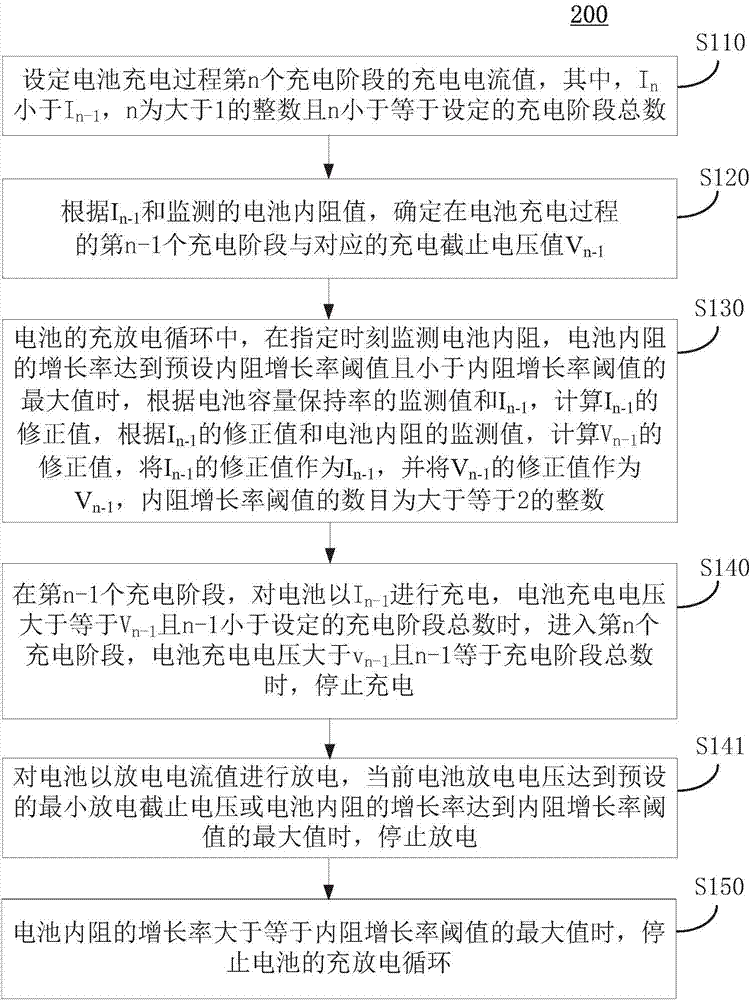

Method used

Image

Examples

specific Embodiment

[0118] Before the start of the selected battery charge and discharge cycle, set the DCR growth thresholds during the battery charge and discharge cycle to 10%, 20%, 30%, 40% and 50%, respectively, and monitor the initial value of the battery internal resistance DCR 0 =1.00mohm, and the maximum charge cut-off voltage of the battery is 4.250V.

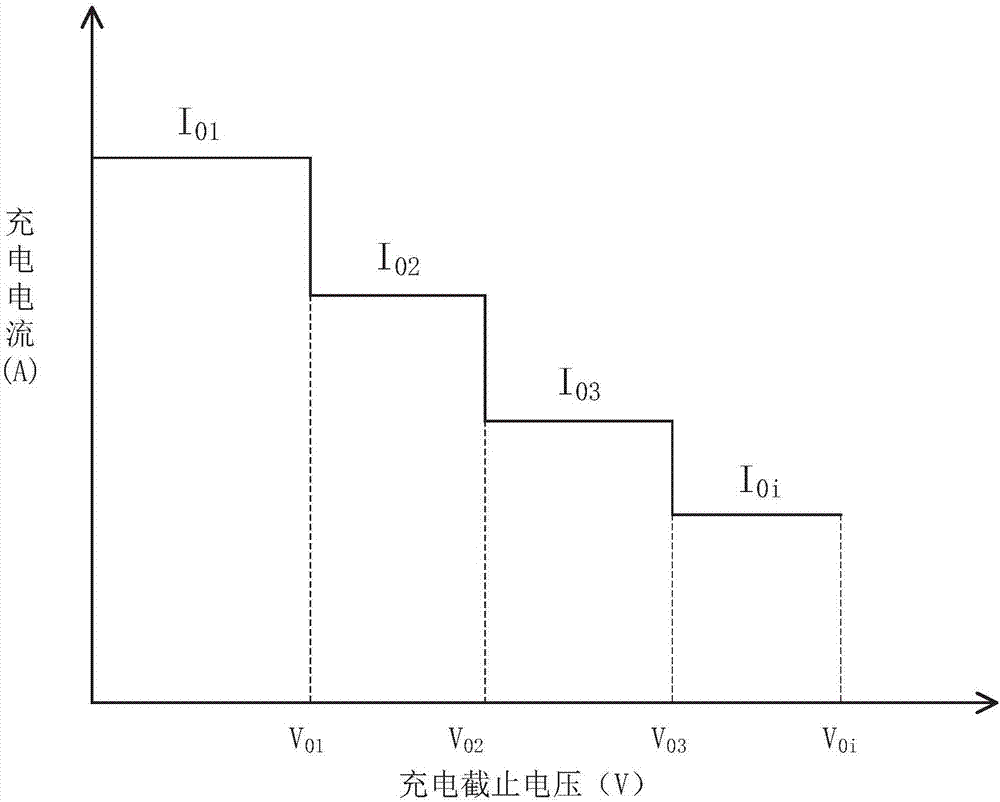

[0119] Set the initial charging current value {80.0A, 60.0A, 40.0A, 20.0A, 10.0A} during the charging process of a group of batteries, and calculate the charging current value corresponding to each stage through the above formula (1). Charge cut-off voltage {4.170V, 4.190V, 4.210V, 4.230V, 4.240V}.

[0120] Figure 5 A schematic diagram of a charging curve at an initial charging current value in a battery charging method according to another embodiment of the present invention is shown.

[0121] like Figure 5 As shown, in the initial stage of the battery charge and discharge cycle, the battery is charged with the set initial charge c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Internal resistance | aaaaa | aaaaa |

| Internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com