A nano-hydroxyapatite/carboxymethyl chitosan/polylactic-glycolic acid micro-nano hybrid drug-loaded scaffold and its bionic preparation method

A technology of nano-hydroxyapatite and carboxymethyl chitosan, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problem of poor hydrophilicity and biocompatibility, lack of cell recognizable sites, lack of Biological activity and other issues, to achieve the effect of improving biological activity, good biocompatibility, and realizing complementary functional advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

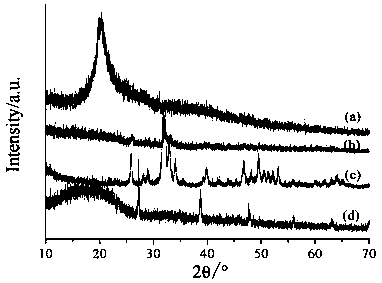

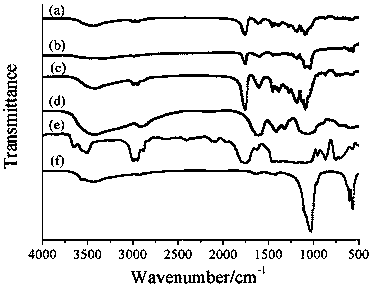

Image

Examples

Embodiment 1

[0040] 1) Disperse 0.075g of nano-hydroxyapatite in 20mL of deionized water, and sonicate for 10min to make it evenly dispersed;

[0041] 2) Add 0.2g carboxymethyl chitosan to it, and stir with a magnetic stirrer for 1h to form a uniform water phase (continuous phase);

[0042] 3) Take 136 µg icariin and add it to the above aqueous phase to prepare a molar concentration of 10 -5 M's icariin solution;

[0043] 4) Dissolve 0.32g of polylactic glycolic acid in 8mL of dichloromethane to prepare the oil phase (dispersed phase) of the emulsion;

[0044] 5) Take 5mL of the emulsion water phase and 2mL of the oil phase, add them to the mold, and add 14.5 µL of glutaraldehyde to it with the molar ratio of amino groups and aldehyde groups at 1:1, and use the Ultra Turrax T25 high-speed emulsifier at 15×10 3 Emulsify at rpm / min, emulsification time is 1min;

[0045] 6) Place the emulsion at room temperature for 12 hours to evaporate the solvent, then transfer it to -10~-80°C and freez...

Embodiment 2

[0047] 1) Disperse 0.15g of nano-hydroxyapatite in 20mL of deionized water, and sonicate for 10min to make it evenly dispersed;

[0048] 2) Add 0.2g carboxymethyl chitosan to it, and stir with a magnetic stirrer for 1h to form a uniform water phase (continuous phase);

[0049] 3) Take 136µg icariin and add it to the above aqueous phase to prepare a molar concentration of 10 -5 M's icariin solution;

[0050] 4) Dissolve 0.32g of polylactic-glycolic acid in 8mL of dichloromethane to prepare the oil phase (dispersed phase) of the emulsion;

[0051] 5) Take 5mL of the emulsion water phase and 2mL of the oil phase, put them into the mold, and add 14.5 µL of glutaraldehyde to it with the molar ratio of amino group and aldehyde group at 1:1, and use the Ultra Turrax T25 high-speed emulsifier at 15×10 3 Emulsify at rpm / min, emulsification time is 1min;

[0052] 6) Place the emulsion at room temperature for 12 hours to evaporate the solvent, then transfer it to -10~-80°C and freeze ...

Embodiment 3

[0054] 1) Disperse 0.3g of nano-hydroxyapatite in 20mL of deionized water, and sonicate for 10min to make it evenly dispersed;

[0055] 2) Add 0.2g carboxymethyl chitosan to it, and stir with a magnetic stirrer for 1h to form a uniform water phase (continuous phase);

[0056] 3) Take 136µg icariin and add it to the above aqueous phase to prepare a molar concentration of 10 -5 M's icariin solution;

[0057] 4) Dissolve 0.32g of polylactic-glycolic acid in 8mL of dichloromethane to prepare the oil phase (dispersed phase) of the emulsion;

[0058] 5) Take 5mL of the emulsion water phase and 2mL of the oil phase, put them into the mold, and add 14.5 µL of glutaraldehyde to it with the molar ratio of amino group and aldehyde group at 1:1, and use the Ultra Turrax T25 high-speed emulsifier at 15×10 3 Emulsify at rpm / min, emulsification time is 1min;

[0059] 6) Place the emulsion at room temperature for 12 hours to evaporate the solvent, then transfer it to -10~-80°C and freeze i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com