Purification equipment

A purification equipment and large particle technology, applied in chemical instruments and methods, dispersed particle filtration, combined devices, etc., can solve the problems of high labor cost, high noise, and high maintenance cost, achieve convenient insertion and discharge, and reduce equipment. The effect of damage and lower maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Exhaust gas environmental protection purification equipment is a kind of equipment that often appears in the industry. It is used to filter polluting treatment and protect the air. However, the use of existing equipment is relatively limited. The large particles of impurities in the exhaust gas cannot be effectively filtered out, and it cannot further prevent the pollution of the exhaust gas. Excessively large particles of impurities entering the pipeline cause unnecessary work intensity, thereby increasing equipment damage and greatly increasing the maintenance rate of industrial waste gas environmental protection purification equipment.

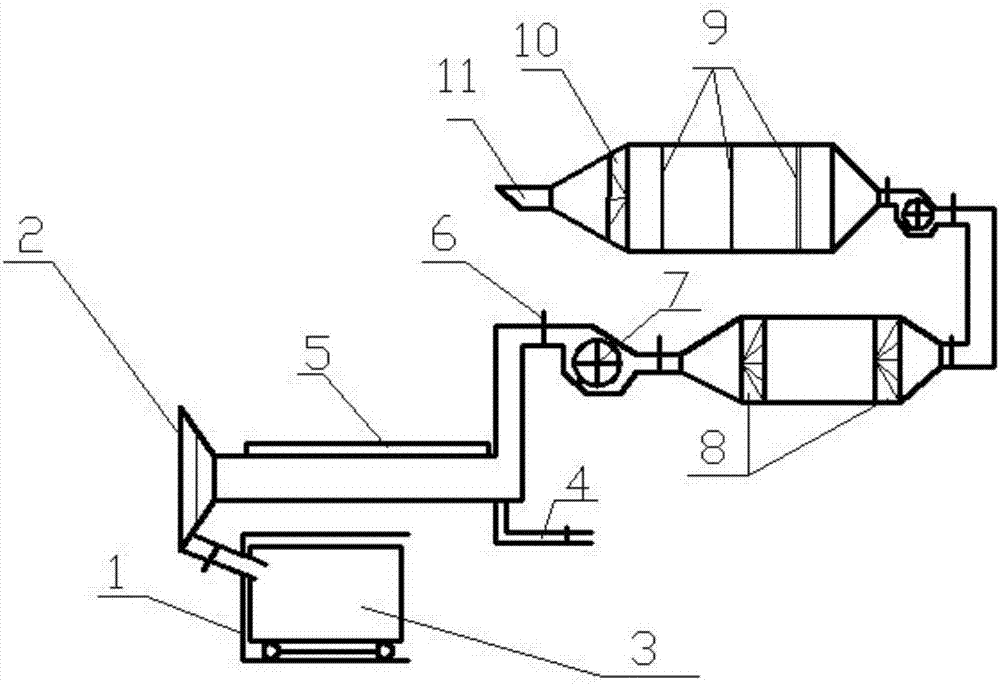

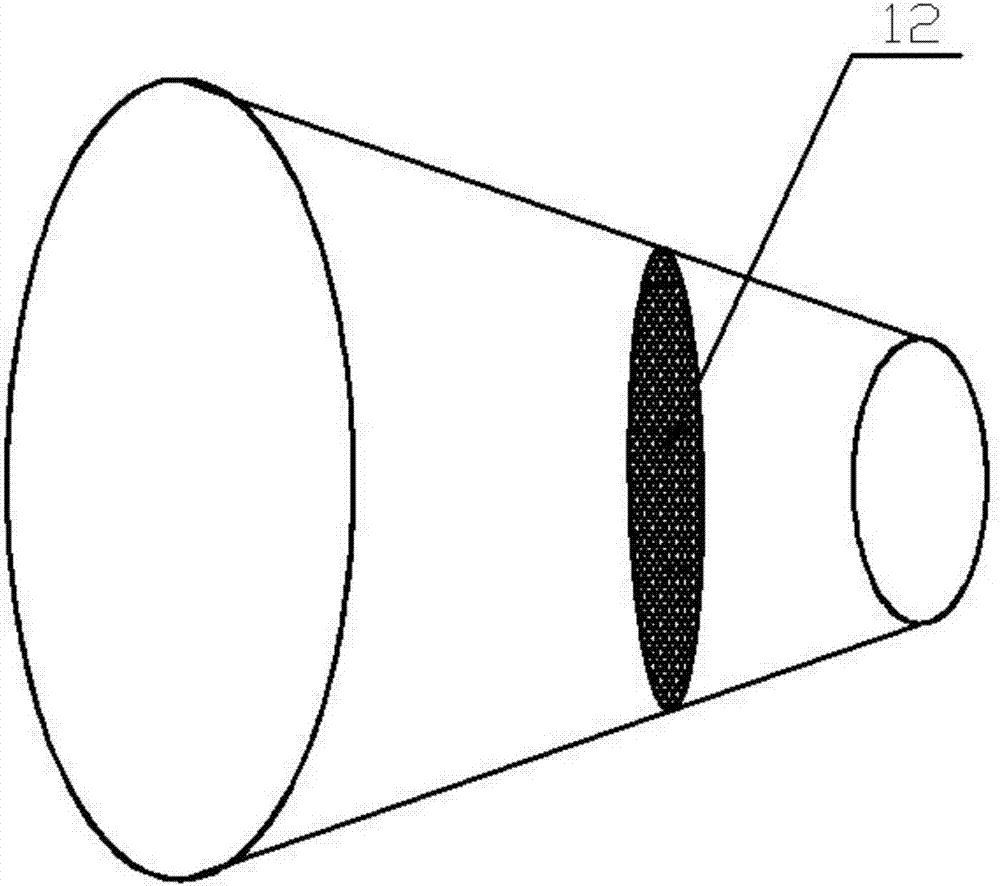

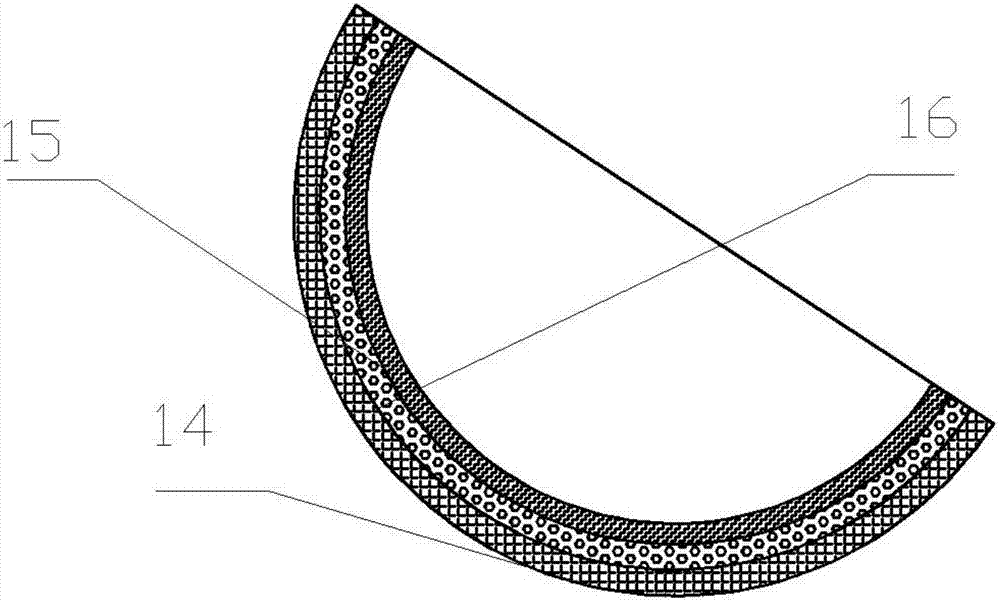

[0017] refer to figure 1 , figure 2 , image 3 , one A kind of purification equipment, its structure includes: large particle collector 1, exhaust gas collection device port 2, large particle collection vehicle 3, drainage device 4, humidifier 5, control valve 6, steam-water separator 8, fan 7, activated carbon adsorption plate 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com