Bonding apparatus of multiple layers of corrugated paper boards

A corrugated cardboard and bonding technology, applied in the field of corrugated paper production, can solve problems such as poor gluing effect and inability to continuously produce, and achieve the effects of reducing production costs, convenient operation, and not easy to deteriorate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

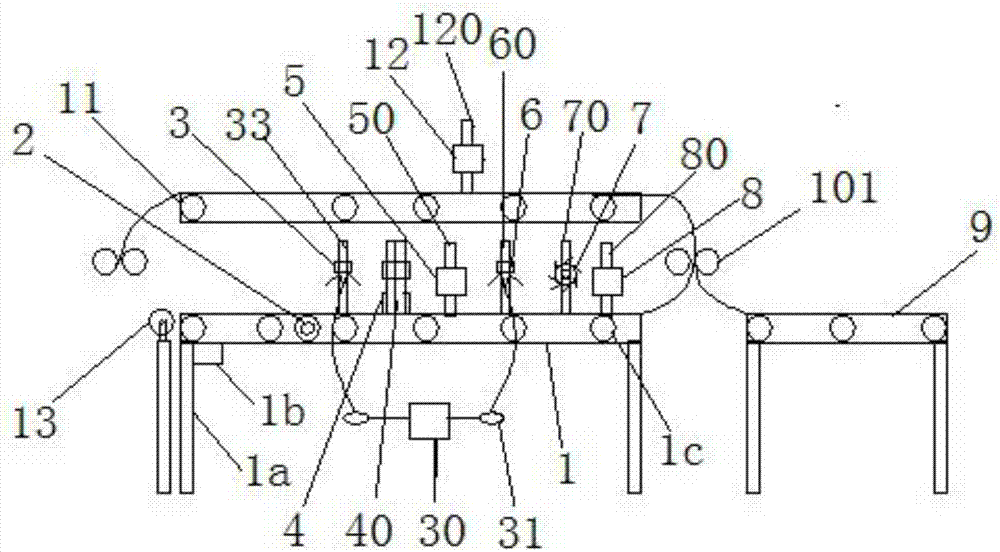

[0036] See figure 1 , a bonding device for multi-layer corrugated cardboard, comprising:

[0037] The first conveying device 1, which is arranged on the frame 1a, the first conveying device 1 includes a motor 1b and a conveying roller 1c, and the conveying roller 1c is connected with the output shaft of the motor 1b through a gear and a chain so that the motor 1b drives the conveying roller 1c to rotate ;

[0038] Preheating device 2, which is arranged on the first conveying device 1, for preheating corrugated paper;

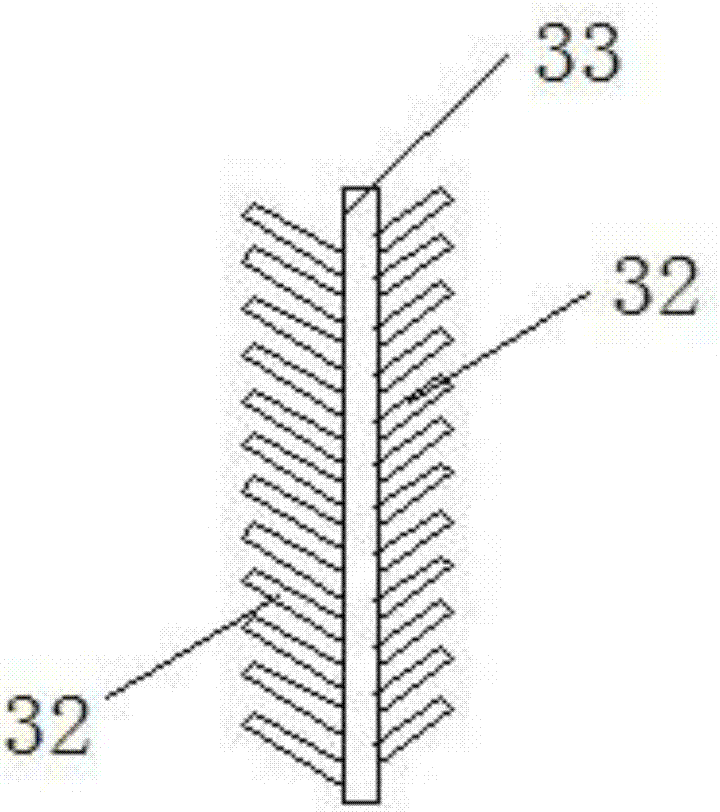

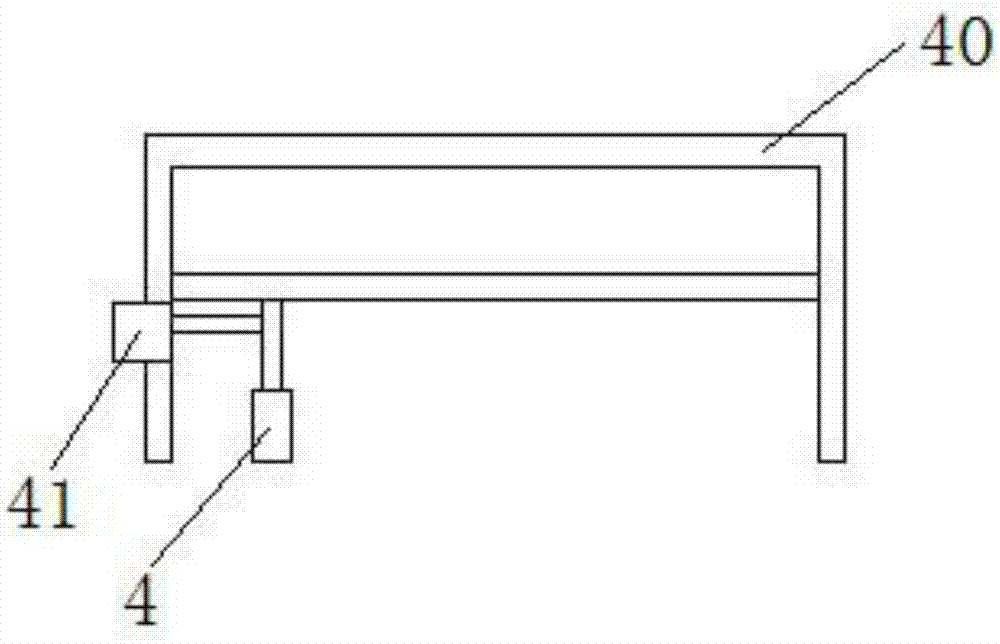

[0039] The first sizing device 3, which is arranged at the output end of the preheating device 2, includes a sizing tank 30 for holding glue, a sizing pump 31, and two groups of sizing nozzles 32, and the two groups of sizing nozzles 32 pass through the The sizing pump 31 is connected to the sizing tank 30, and two groups of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com