A reverse osmosis water purifier

A water purifier and reverse osmosis technology, applied in the direction of osmosis/dialysis water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of shortened filter life, high replacement frequency, and user inconvenience, and achieve The effect of prolonging the service life and reducing the frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

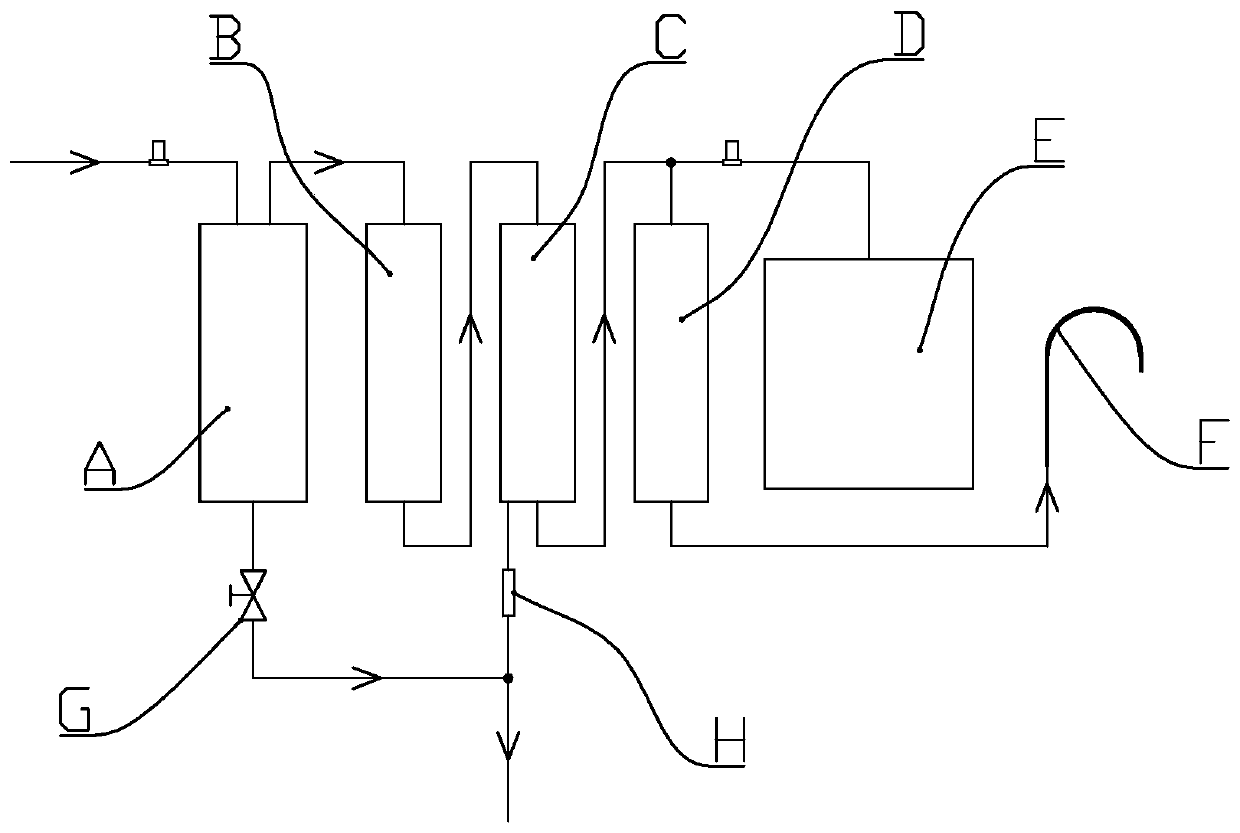

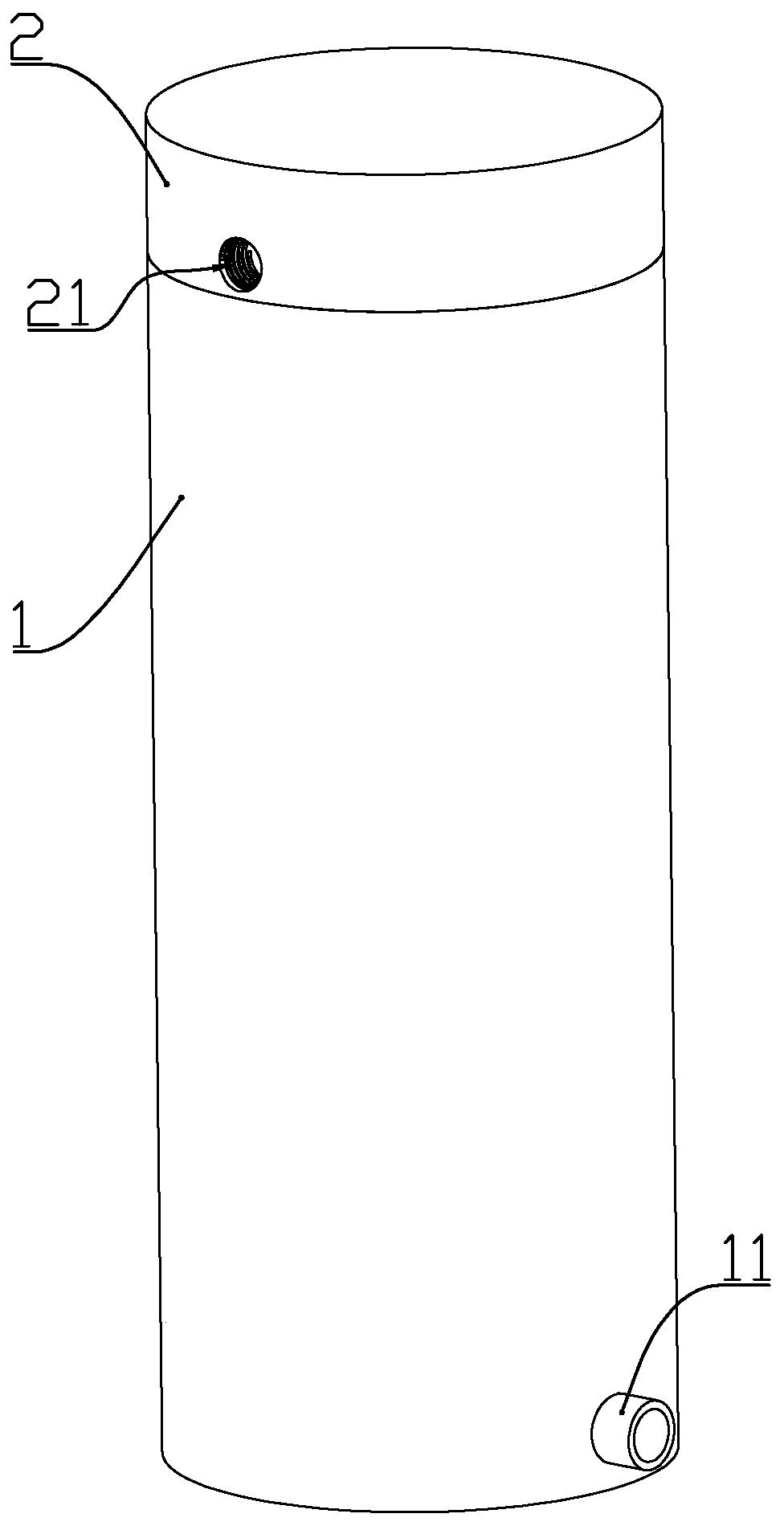

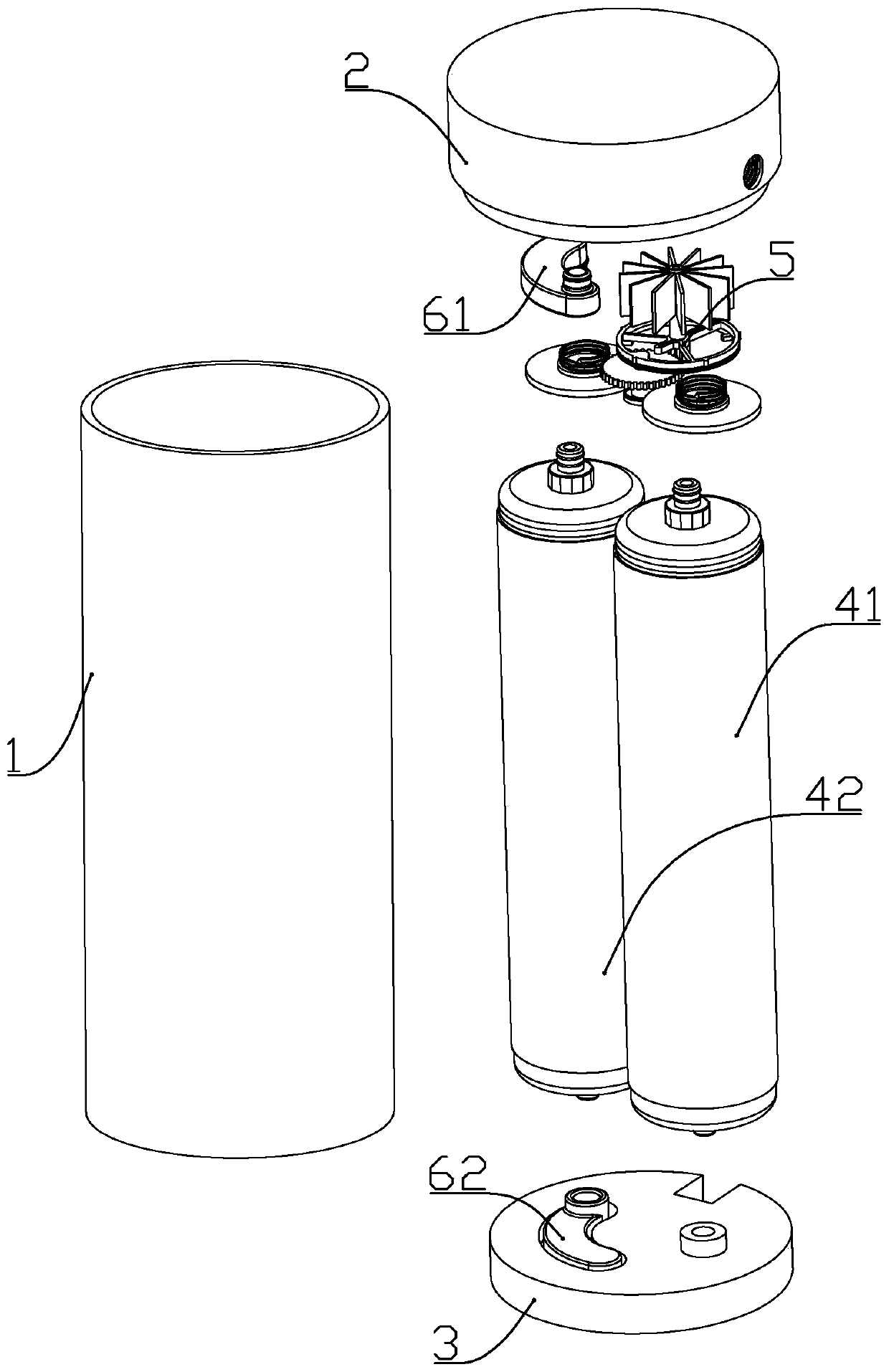

[0058] according to Figure 1 to Figure 15 As shown, a reverse osmosis water purifier described in this embodiment includes a ceramic filter A, a granular activated carbon filter B, a reverse osmosis membrane filter C and a post activated carbon filter D connected sequentially through pipelines.

[0059] The ceramic filter has a water inlet interface, a water outlet interface and a waste water outlet joint, the water inlet interface is connected to a water pipe, the water outlet interface is connected to the water inlet end of the granular activated carbon filter, and the waste water outlet joint is connected to an electromagnetic valve G.

[0060] The reverse osmosis membrane filter has a water inlet, a water outlet and a waste water outlet, the water inlet is connected to the water outlet of the granular activated carbon filter, the water outlet is connected to the water inlet of the rear activated carbon filter, the The waste water outlet is connected with a waste water ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com