External wall system repair method

A technology for exterior walls and walls, applied in the field of building construction, can solve problems such as water seepage, decoration damage, high humidity of insulation cotton, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

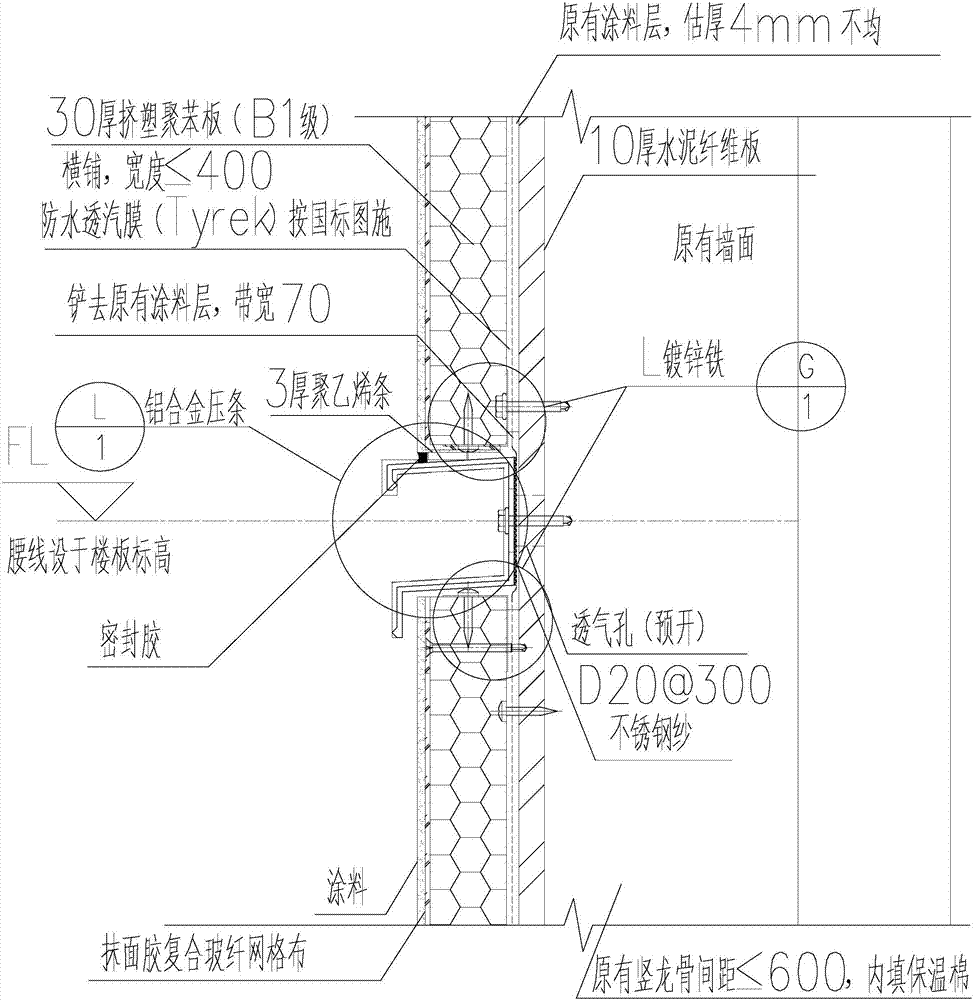

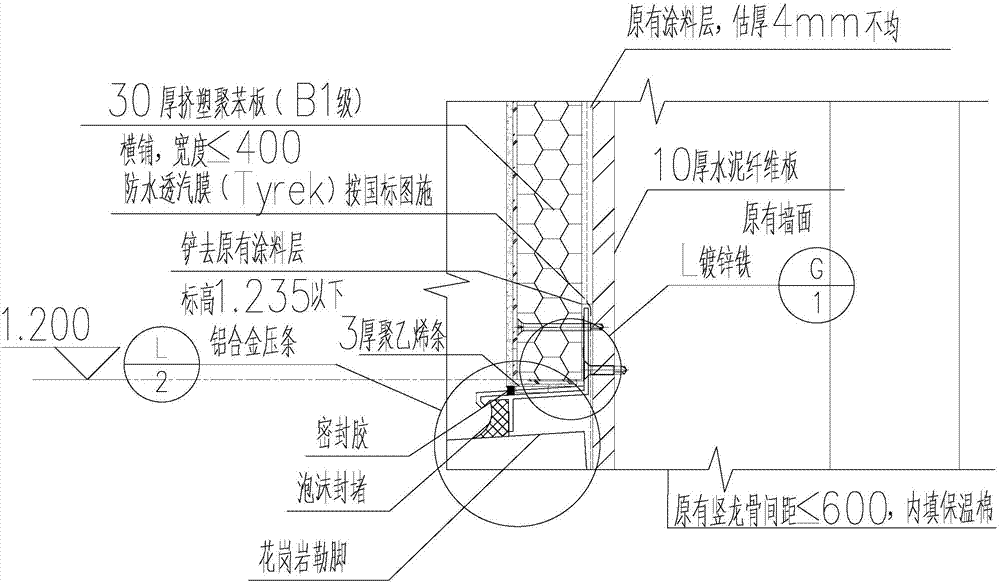

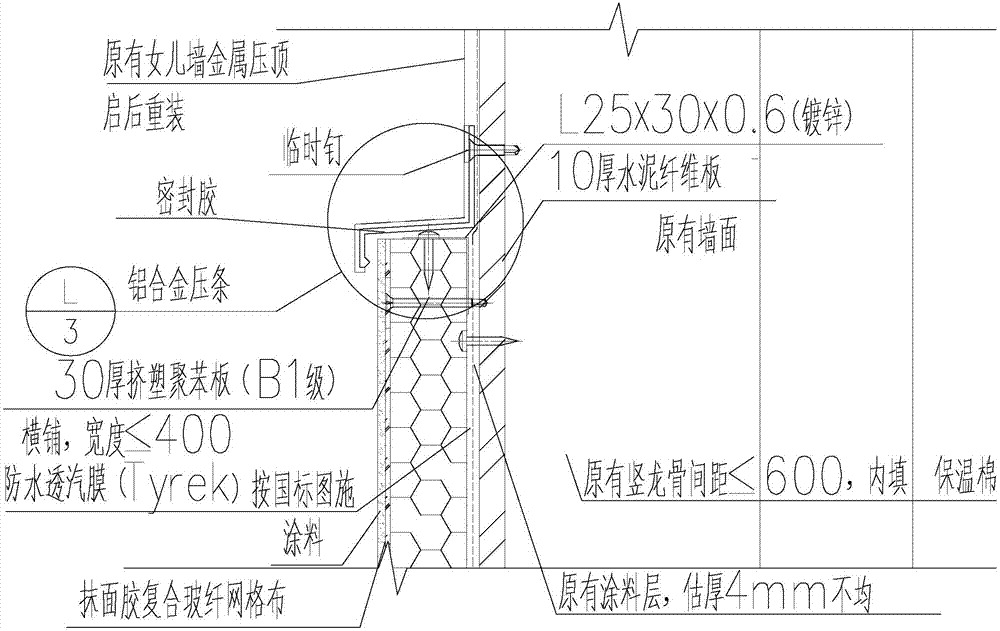

Image

Examples

Embodiment Construction

[0032] (1) Wall pretreatment:

[0033] ① Investigate the outer wall, mainly investigate the parts suspected of serious water ingress, cut the inner wall at these parts, and check the moisture content of the insulation cotton. When the vertical compression deformation of the insulation wool exceeds 3% due to the serious water content of the rock wool, or the compression of a single piece of insulation wool exceeds 3cm, or the insulation wool is damaged, it is considered serious. At this time, the insulation wool should be replaced, and the keel and connection rust should be observed at the same time. case, deal with it separately.

[0034] ②Temporarily seal the cracked gaps in the outer wall to prevent further water ingress during construction.

[0035] ③ Grind the protruding particles of the imitation stone coating so that the G / 1 keel can be adhered to. For the parts that should be leveled according to the design requirements, the coating should be leveled so that the alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com