Arrangement type for electric control high-pressure common rail systems on marine high-speed high-power diesel engines

A high-pressure common rail system, high-power diesel engine technology, applied in electrical control, charging system, mechanical equipment, etc., can solve the problem of engine runaway, the layout of the electronically controlled high-pressure common rail system is not mentioned, not mentioned, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings, and the parts not described in detail herein are prior art;

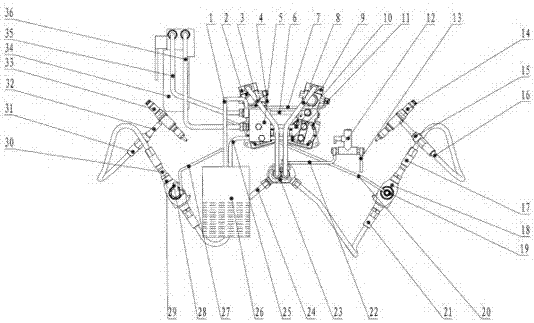

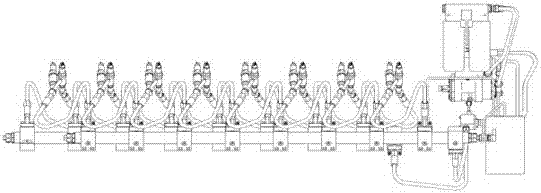

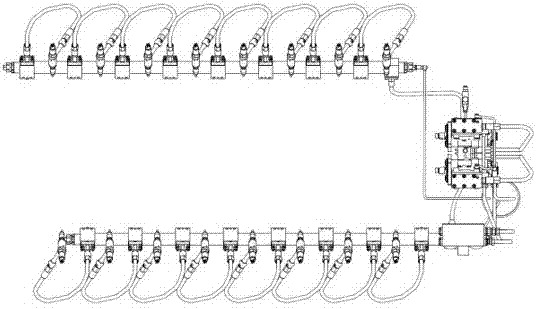

[0017] Such as figure 1 shown, and refer to figure 2 , image 3, an arrangement type of an electronically controlled high-pressure common rail system in a marine high-speed and high-power diesel engine, the electronically controlled high-pressure common rail system has two common rail fuel injection pumps: common rail fuel injection pump I2, common rail fuel injection pump II9; The common rail fuel injection pump Ⅰ2 and the common rail fuel injection pump Ⅱ9 are respectively set corresponding to the common rail pipes 29 of column B and the common rail pipes 17 of column A; the common rail pipes 18 of column A and the common rail pipes 29 of column B are symmetrically arranged in V The A side and the B side of the diesel engine; the common rail pipes 18 of the A row and the common ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com