Thermo-balance

A technology of high-temperature balances and balances, applied in measuring devices, instruments, aerodynamic tests, etc., can solve the problems of large size, small temperature difference, complex structure, etc., and achieve the effect of optimized shape structure, reduced impact, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] The technical solutions of the present invention will be described in more detail below in conjunction with the accompanying drawings.

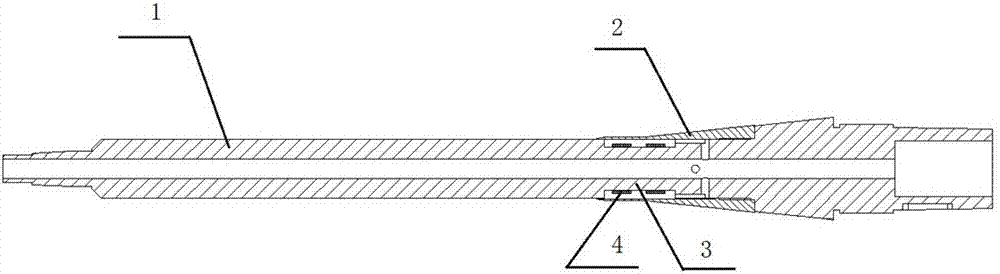

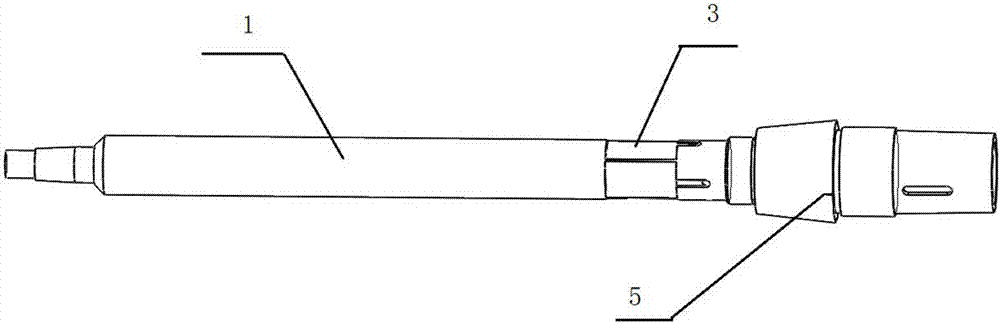

[0023] figure 1 It is a schematic diagram of the three-dimensional structure of the high-temperature balance of the present invention. The balance pole 1 is an integral rod-shaped structure. The front end is matched with the test model through a cone section, and the screw thread is connected to the test model. The rear end is connected by a double-ended nut. It is connected to the support mechanism by means of a balance rod 1. At the end of the straight section of the balance pole 1, there is a square force-sensitive beam 3 for pasting the sensitive element 4. Threads are provided behind the force-sensitive beam 3. The protective sleeve 2 is connected to the balance by threads. On the pole 1, the sensitive element 4 is protected from the test air flow. A marking groove 5 for marking the measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com