Test consumables management method and management system

A management method and technology of a management system, applied in the field of test consumables management method and a test consumables management system, can solve problems such as fabric management confusion, achieve the effects of convenient reading and recording, convenient identification and recording, and avoiding management confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

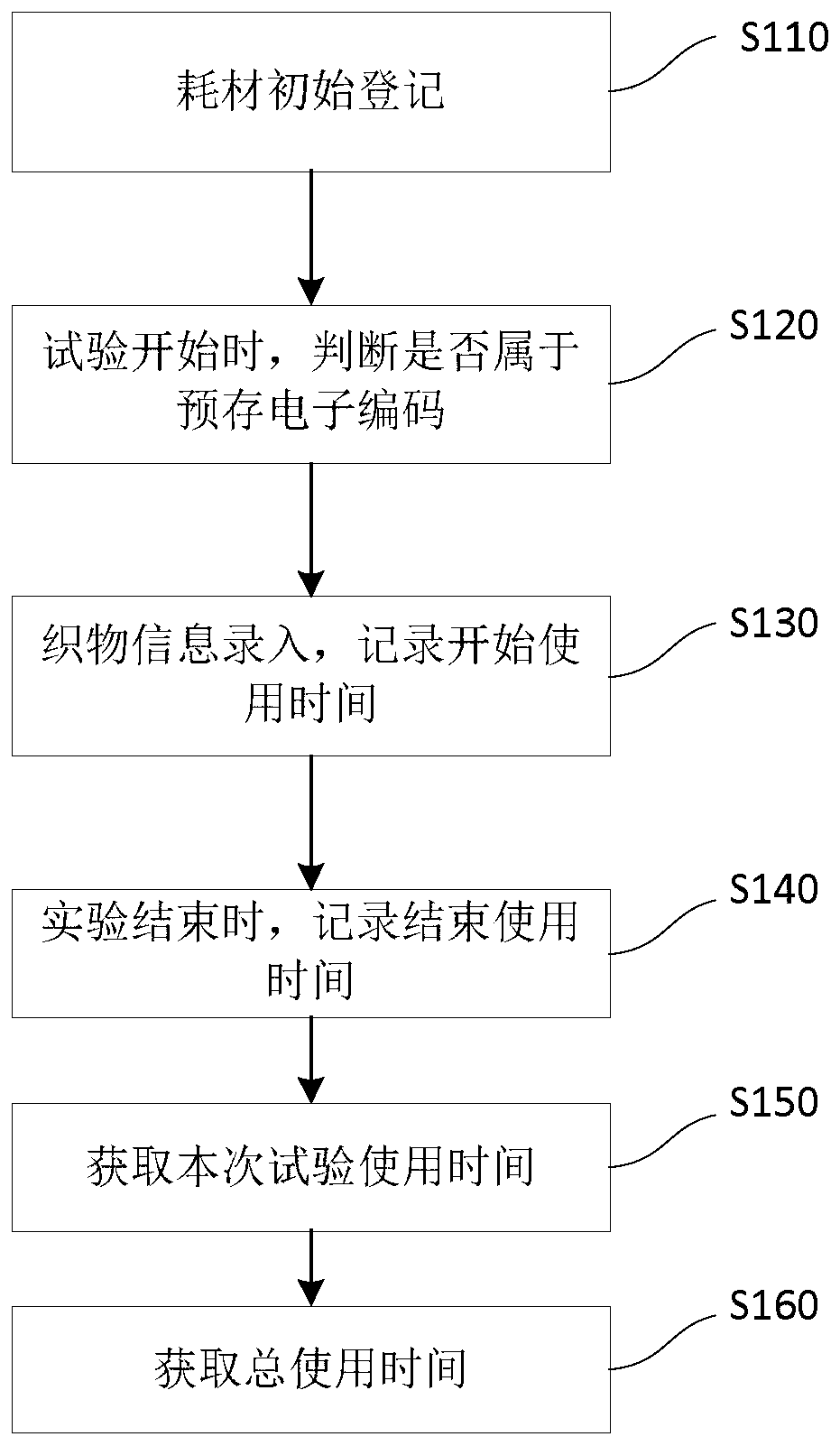

[0060] Such as figure 1 As shown, the embodiment of the present invention provides a method for managing test consumables, the consumables include fabrics and chemical reagents, and the management method includes the following steps,

[0061] S110. Enter the electronic code of each test consumable into the system for registration by scanning or inputting. Only the consumables whose electronic code information has been registered in this step can be used. This step is to avoid misuse of non-laboratory consumables. Prerequisites for consumables management.

[0062] The information of the test status mark can also be obtained; the information can be obtained through software input, or through the hardware button. The test state mark information is divided into two types, one is the start of the test, the other is the end of the test, and the test starts, indicating that this test It is about to be carried out, and the information obtained by scanning will be considered as the in...

Embodiment 2

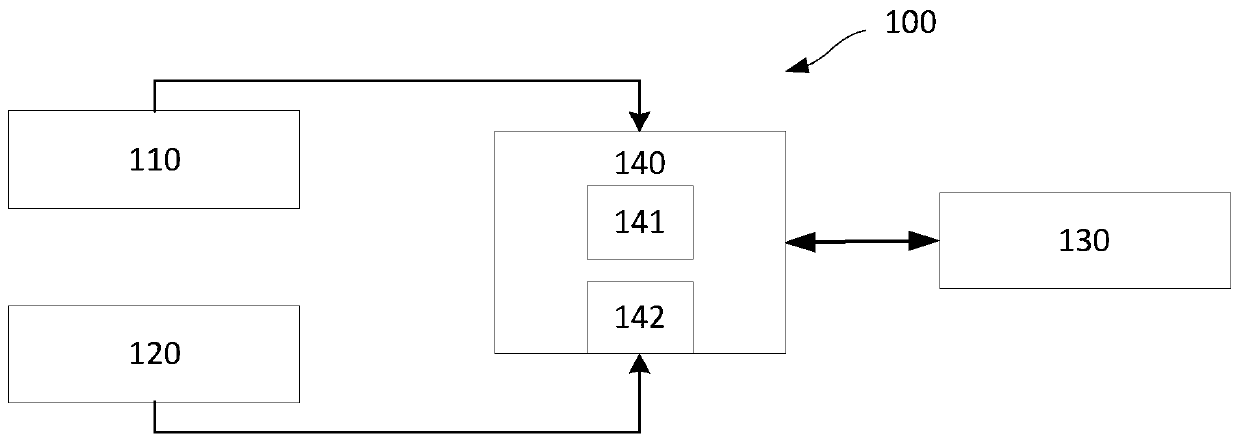

[0084] Another aspect of the present invention, such as figure 2 As shown, a test consumables management system 100 is also provided, including an electronic code reading device 110, a weighing device 120, a database device 130 and a connection with the electronic code reading device 110, weighing device 120 and database device 130 The information processing device 140; the electronic code reading device 110 is used to read the electronic code on the fabric, and the electronic code is sent to the information processing device 140; the weighing device 120 is used to read The weight information of the consumables (fabrics before and after the test, chemical reagents before the test), the weight information is sent to the information processing device 140; the database device 130 is used to store pre-stored electronic code information and elapsed time, etc. Related information, the pre-stored electronic code information is sent to the information processing device 140; when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com