Clean gas cabin

A pure and gas chamber technology, applied in the field of pure gas chamber, can solve the problems of increased bottom load and heavy weight of the inert gas shell, and achieve the effect of small weight, high mechanical load capacity and simplified installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

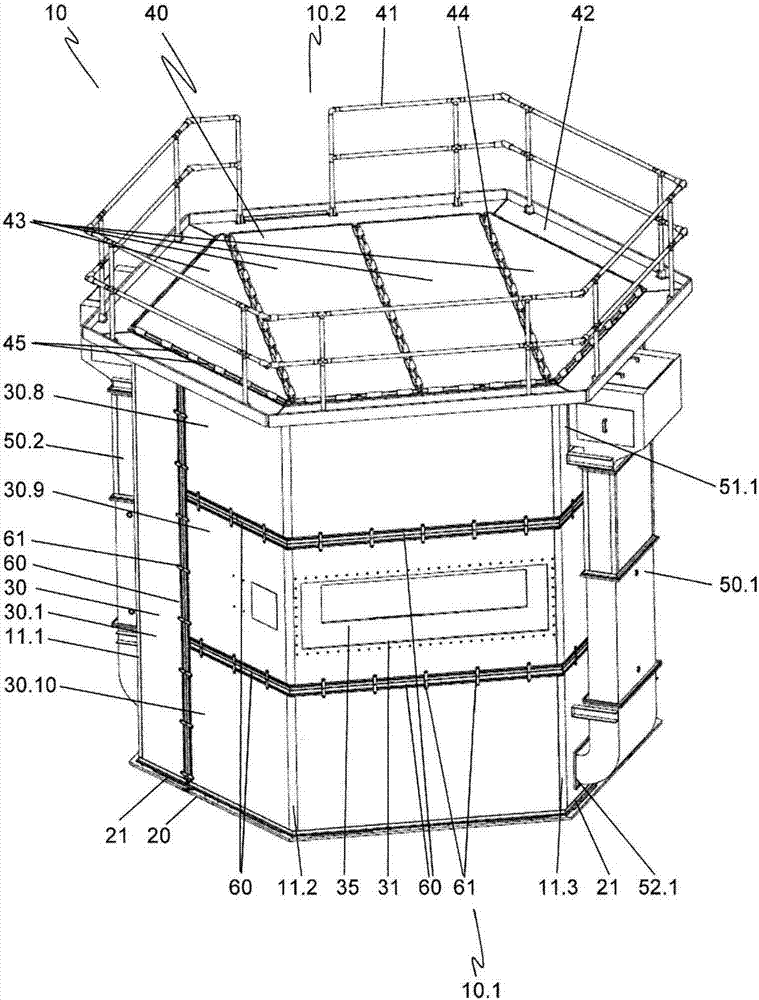

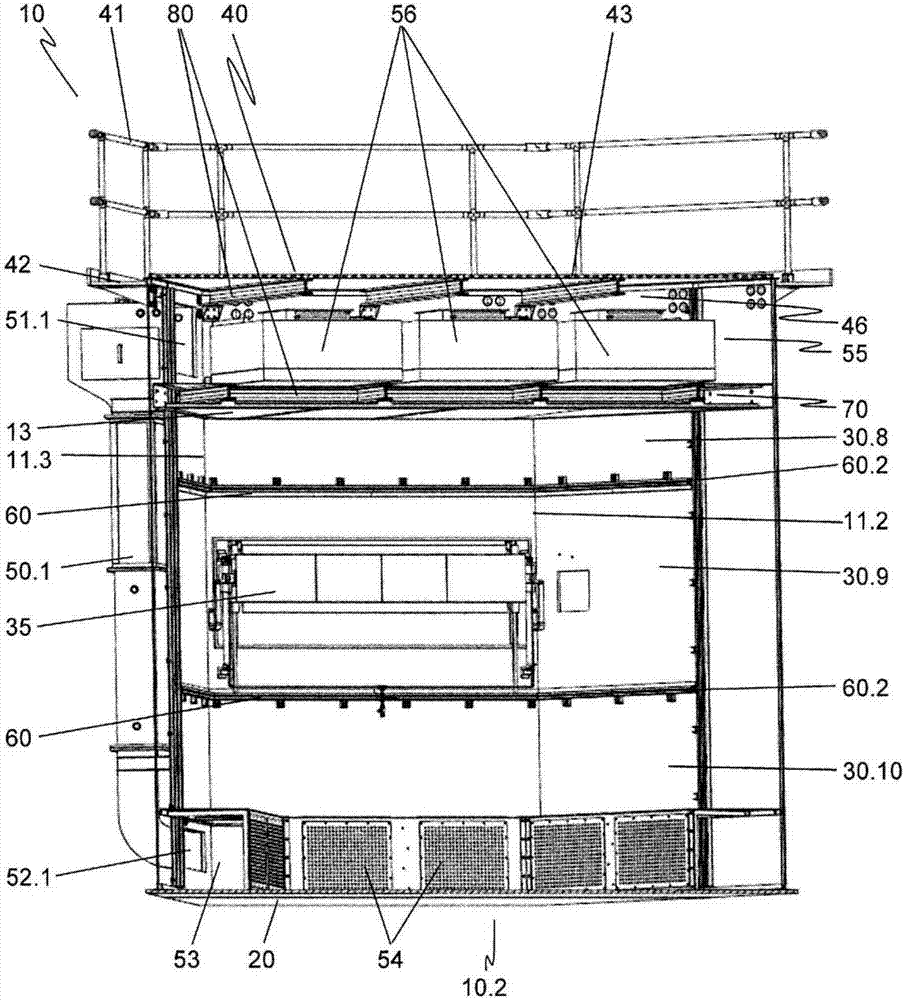

[0046] figure 1 The pure gas chamber 10 is shown in a perspective external view. For easier transfer to the following embodiments, the front side 10.1 and the rear side 10.2 of the pure gas chamber 10 are freely set.

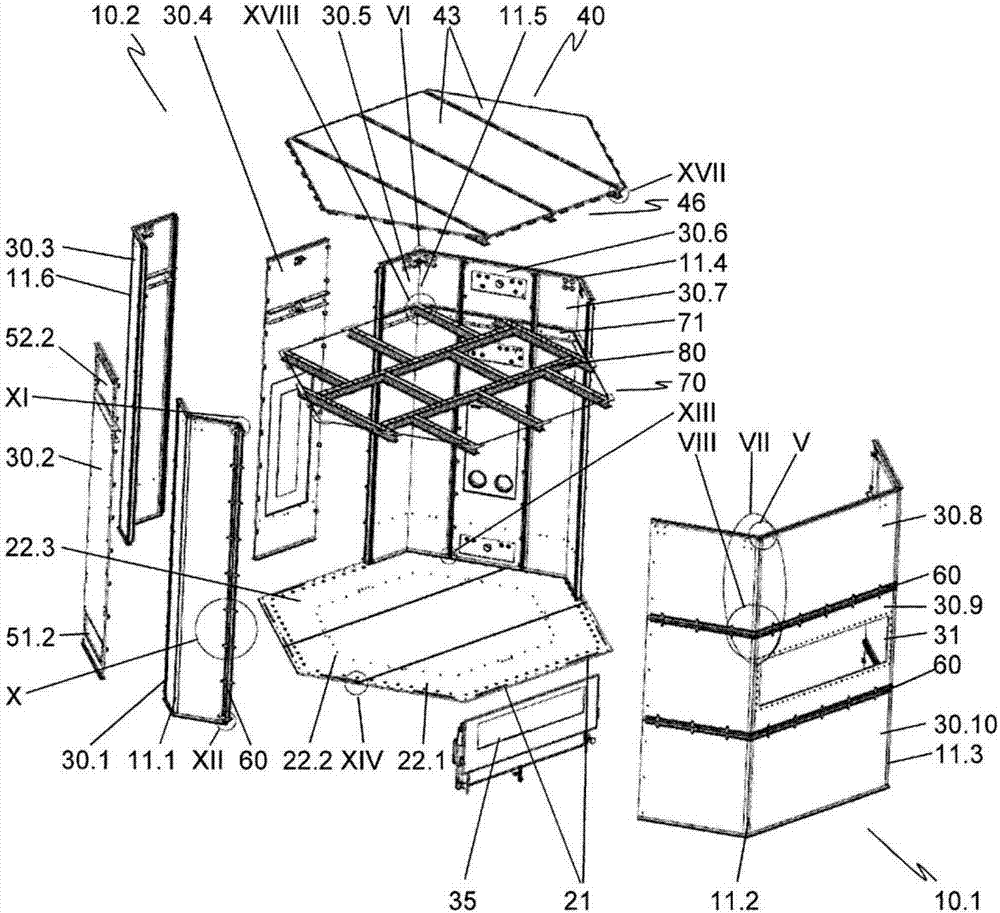

[0047] The pure gas chamber 10 has a polygonal plan shape. In the illustrated embodiment, the planar shape is a hexagon. A plurality of side walls 30 are built on the corresponding hexagonal base 20 . For this purpose, the side walls 30 are oriented according to the positioning element 21 which is mounted on the outer side of the base 20 . In the selected view of the front side 10.1, the left side is provided with a first vertical side wall 30.1 and a first horizontal side wall 30.8, a second horizontal side wall 30.9 and a third horizontal side wall 30.10 arranged one above the other. Other vertical side walls 30.2, 30.3, 30.4, 30.5, 30.6, 30.7 are in image 3 shown in . The first vertical side wall 30.1 comprises the first corner 11.1 of the pure gas cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com