Adjustable subsoiler fixing device

A fixing device and subsoiling shovel technology, applied in the field of fixing devices, can solve the problems of inability to adjust the subsoiling angle of the subsoiling shovel, occupying the usable space of the frame, easy deformation of the subsoiling shovel, etc., achieving significant advantages in use performance and saving production costs. , installation time-saving and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

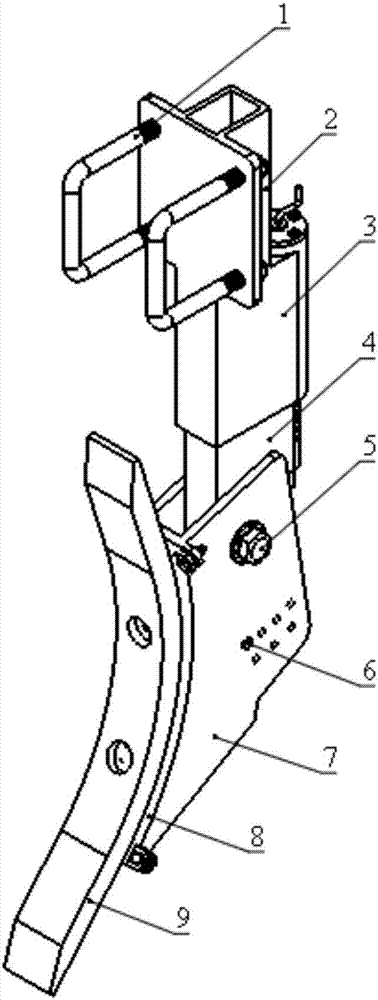

[0022] Now in conjunction with accompanying drawing, the present invention will be further described, as Figure 1 to Figure 4 As shown, the present invention includes a depth adjustment group, an angle adjustment group and a shovel holder.

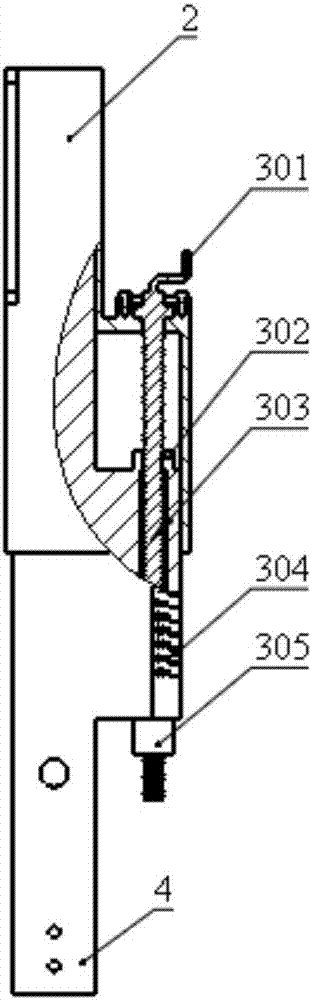

[0023] The depth adjustment group includes a guide cylinder 2 , a depth adjustment unit 3 , and a shovel handle 4 . The depth adjustment unit 3 includes an adjustment handle 301 , an upper fixing nut 302 , a screw rod 303 , a scale scale 304 , and a lower fixing nut 305 .

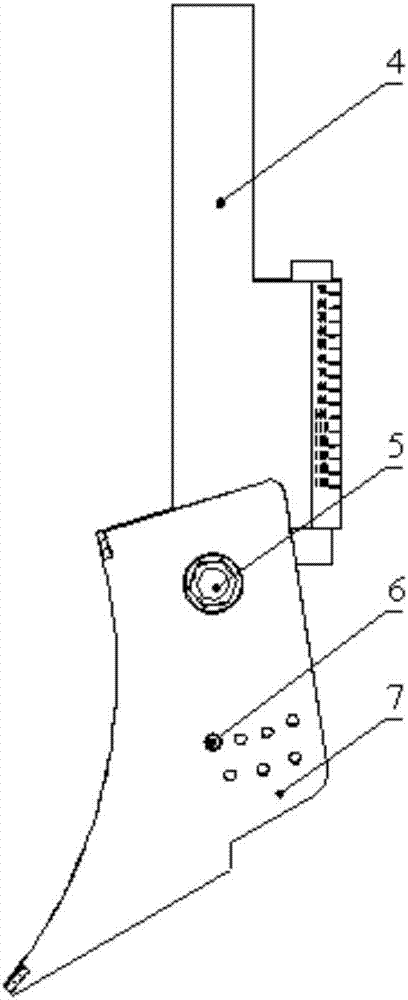

[0024] The angle adjustment group includes an angle adjustment seat 7 , a bolt 5 and a safety pin 6 .

[0025] In this example, if figure 1 , the guide cylinder 2 that plays the role of fixed support and guide rail is fixed on the beam of the existing subsoiler frame by the connection mode of U-shaped bolt 1 and nut, and is in a vertical installation state. The upper part of the shovel handle 4 can slide up and down inside the guide cylinder to realize the adjustabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com