Microfluidic syringe filter head and use method thereof

A syringe and microfluidic technology, which is applied in the field of syringe filter heads, achieves the effects of reducing volume, facilitating miniaturization and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

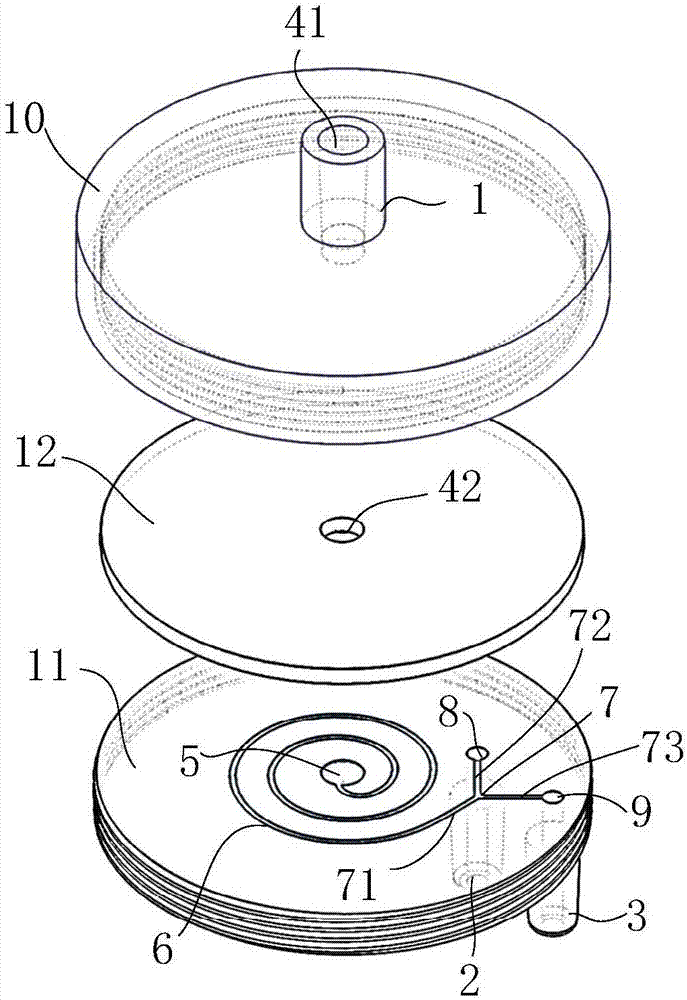

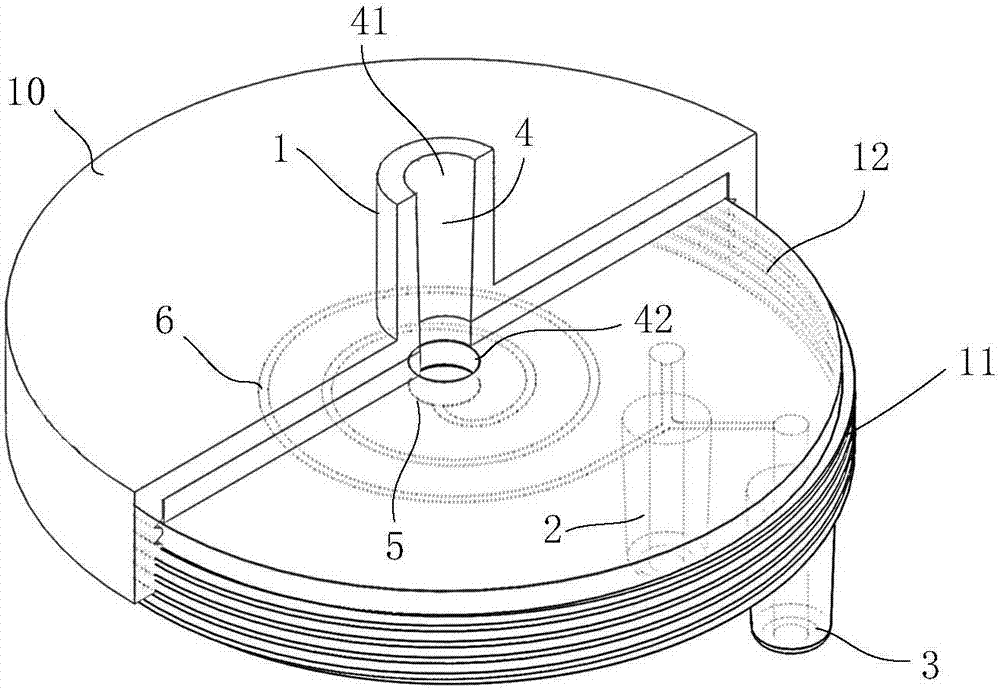

[0024] The implementation modes of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] The microfluidic syringe filter head of the present invention is a miniaturized filter head that can be directly connected to a syringe. The filter head adopts microfluidic technology to realize rapid concentration of micron particles and biological cells.

[0026] like figure 1 As shown, a microfluidic syringe filter head, its body structure includes an upper cover 10, a concentration component 11 and a sealing gasket 12, the upper cover 10 is tightly connected with the concentration component 11, and the sealing gasket 12 is arranged between the upper cover 10 and the concentration component 11 between. Among them, the upper cover 10 and the concentration component 11 can be made of materials such as medical plastics and stainless steel through injection molding, machining, three-dimensional additives and other processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com