Oblique angle cutting hole saw

A technology of bevel cutting and hole sawing, which is applied in the direction of drilling/drilling equipment, drilling tool accessories, transportation and packaging, etc. It can solve the problems of reducing the service life of the saw teeth, prone to vibration, easy to damage the saw teeth, etc., to improve processing Efficiency, avoidance of slippage, and improvement of centering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

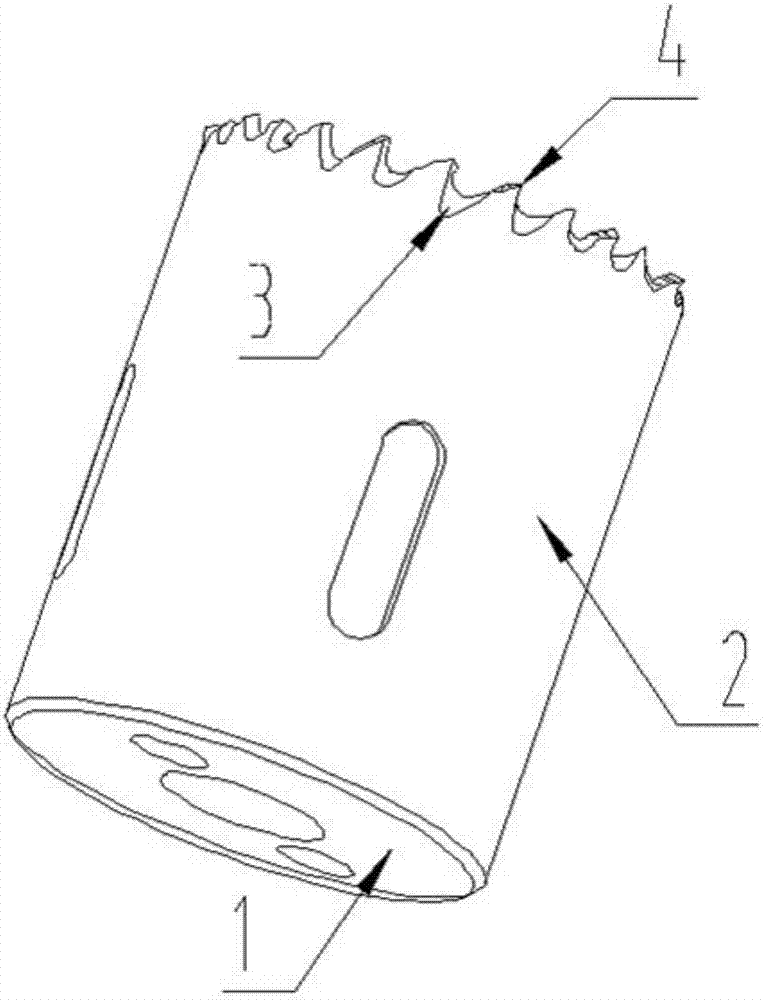

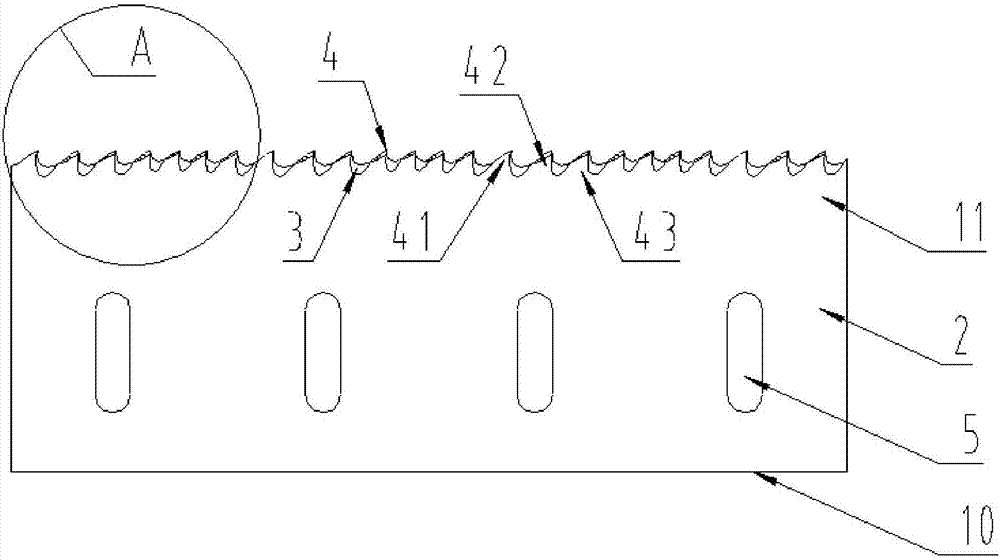

[0031] Such as figure 1 and figure 2 As shown, a bevel cutting hole saw includes a base 1, a saw body 2 and saw teeth 4, the lower end of the saw body 2 is connected to the base 1, the side wall of the saw body 2 is provided with evenly distributed side wall openings 5, and the saw body The upper end 11 is provided with a sawtooth 4, said sawtooth 4 is composed of multiple sets of sawtooth arranged in a cycle, each set of sawtooth includes a right sawtooth 42 biased toward the inner surface of the saw, a left sawtooth 43 biased to the outer surface of the saw, a guide tooth 41, and a right sawtooth 42 , left saw teeth 43 and guide teeth 41 are arranged alternately.

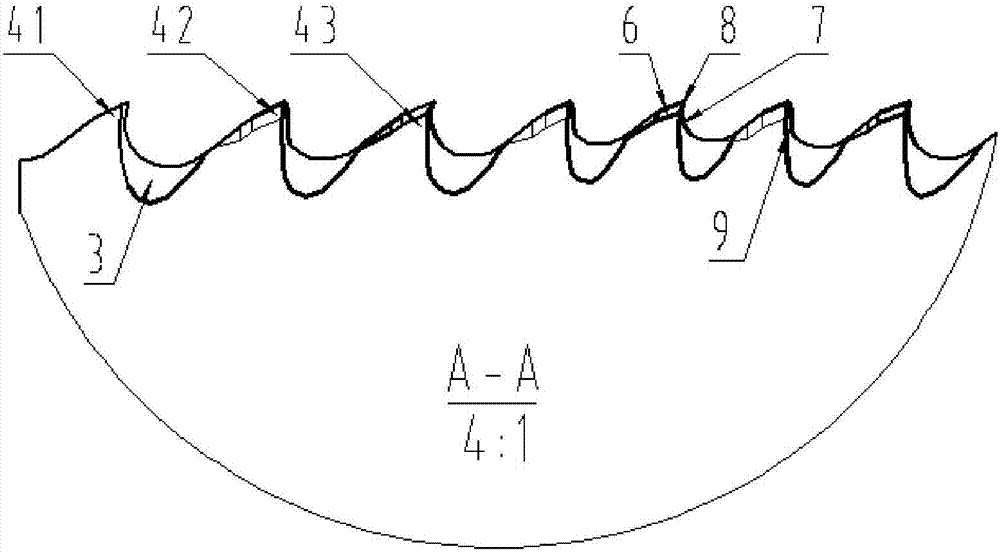

[0032] Such as image 3 As shown, the sawtooth cutting edges 8 formed by the intersection lines of the rake face 7 of the guide tooth 41, the right sawtooth 42 and the left sawtooth 43 and the flank 6 are all inclined straight lines, and the inclination direction is the same. It is an arc-shaped slope, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com