Flat-cup non-slip bolt bar knurling and thread rolling device

A bolt and anti-slip technology, which is applied in the field of screw processing, can solve the problems of low processing precision, occupying storage space, easy rolling and skewing, etc., to achieve high-precision processing, improve processing efficiency, and avoid the effect of knurling skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

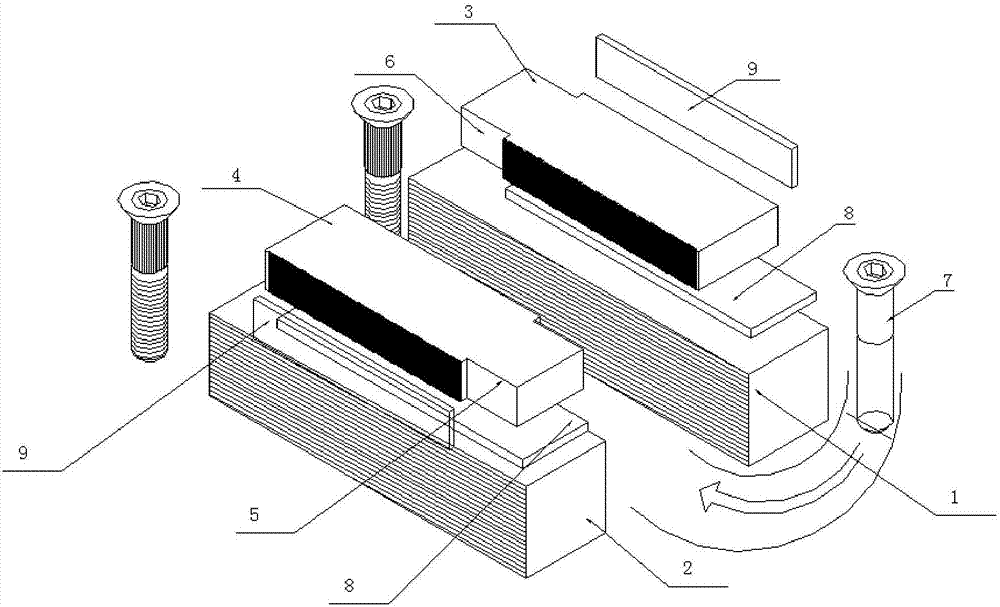

[0014] Embodiment: A kind of knurling and thread rolling device of flat cup anti-slip bolt shank, comprising movable die rubbing board 1, fixed die rubbing board 2, moving die knurling board 3 and fixed die knurling board 4, the moving die Die rubbing plate 1 and fixed die rubbing plate 2 are set facing each other, movable die knurling plate 3 and fixed die rubbing plate 4 are set oppositely, and moving die knurling plate 3 is fixedly positioned on the front of movable die rubbing plate 1. Above, the fixed die knurling plate 4 is fixedly positioned directly above the fixed die rubbing plate 2, and the opposite side walls of the movable die rubbing plate 1 and the fixed die rubbing plate 2 are respectively formed with rubbing patterns, and the moving die knurling plate 3 and the opposite side walls of the fixed die knurling plate 4 are respectively formed with knurling patterns, and the movable die rubbing plate 1 and the movable die knurling plate 3 can be opposite to the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com