Adjustable scrap prevention cover

An adjustable anti-dust cover technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of difficult cleaning of iron filings, large quantities, environmental pollution, etc., and achieve easy chip removal, opening and closing Convenience, fixed structure and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

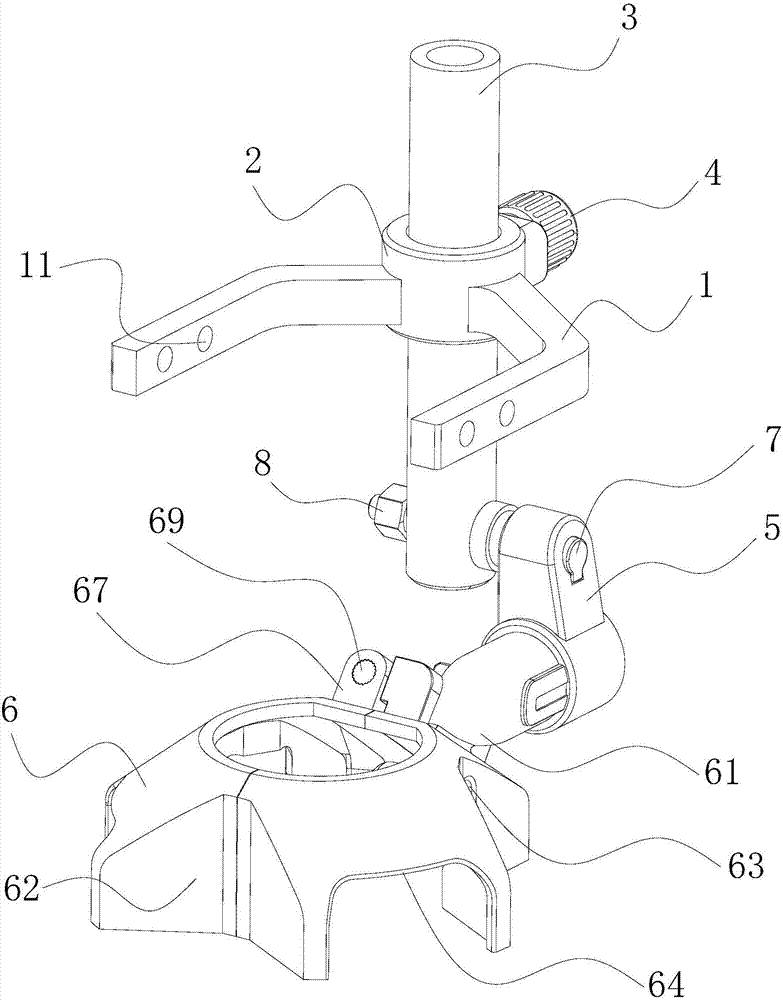

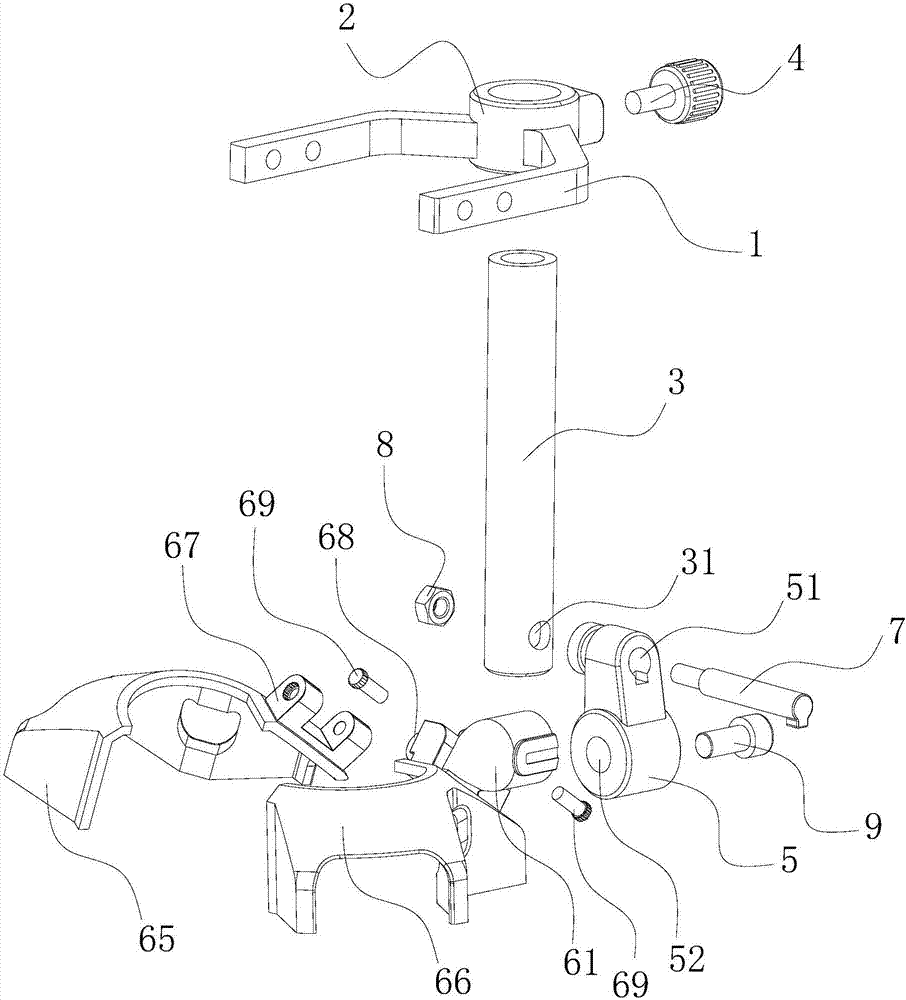

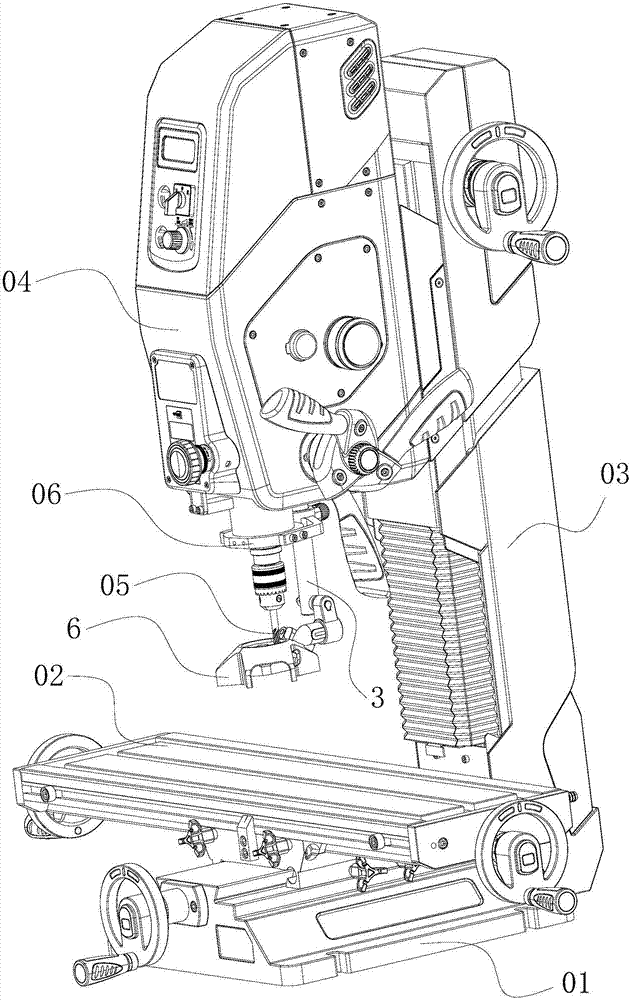

[0016] See Figure 1-Figure 3 , an adjustable anti-dust cover, including a transparent cover 6 that penetrates up and down, a clamping and fixing frame 1, a lifting shaft 3 and a connector 5; the clamping and fixing frame 1 is a U-shaped structure, and the middle part is provided with a vertical The sleeve 2 is provided with installation and fixing holes 11 on both parallel parts, the upper part of the lifting shaft 3 passes through the sleeve 2, and a locking bolt 4 passes through the side wall of the sleeve 2 to press the lifting shaft 3; the connector 5 It includes the connecting part of the lifting shaft at the upper part and the connecting part of the casing at the lower part. The bottom of the lifting shaft 3 is provided with a through horizontal through hole 31, and the connecting part of the lifting shaft is provided with an upper connecting hole 51 communicating with the horizontal through hole 31. The rotating shaft 7 passes through the upper connecting hole 51 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com