Fully closed type in-pipe traction mechanism

A traction mechanism and closed technology, applied in the field of in-tube traction mechanism, can solve the problems of serious heat dissipation, no targeted closed structure, low energy utilization rate, etc., and achieve the effect of ensuring processing quality and realizing rapid and continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

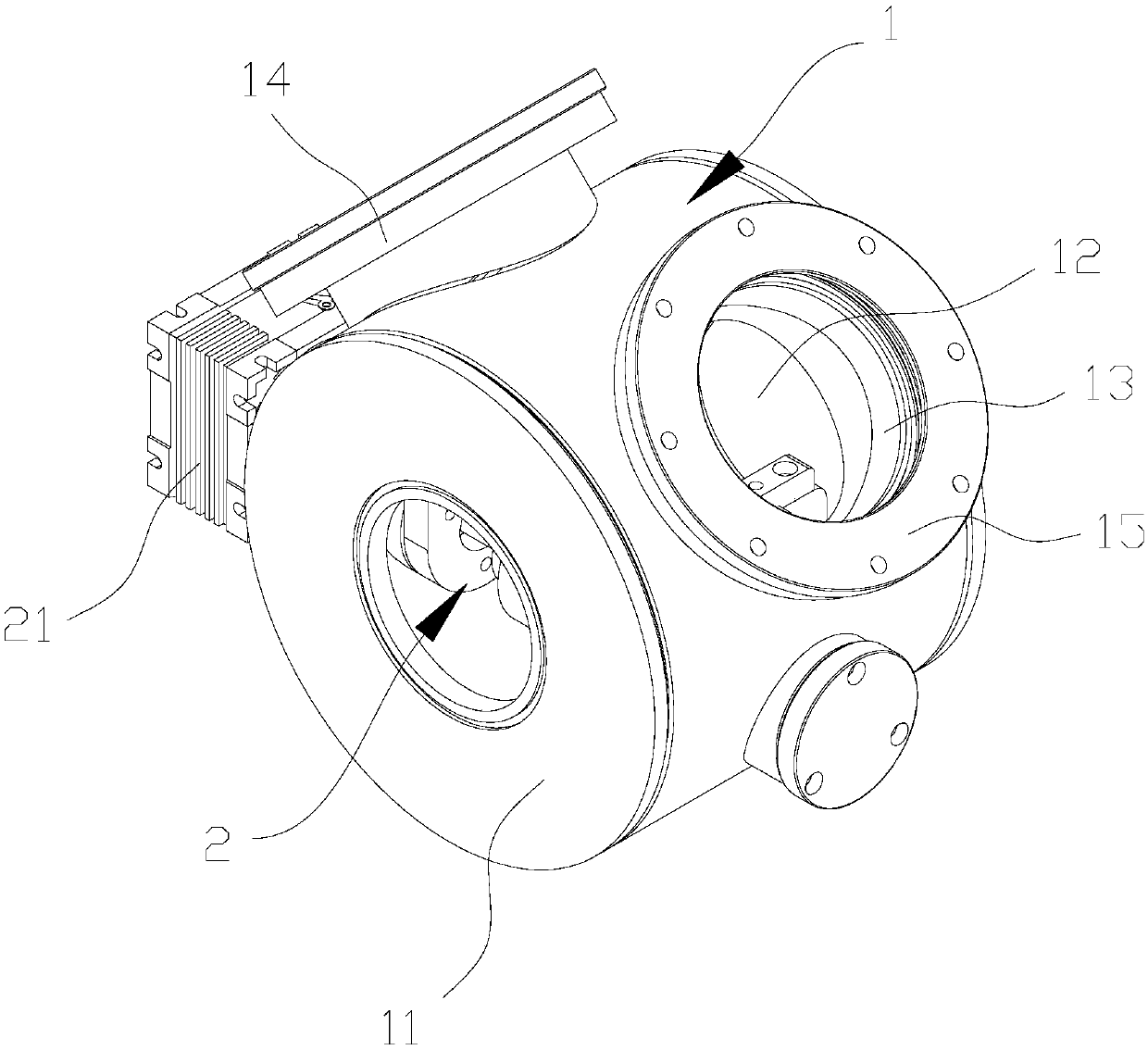

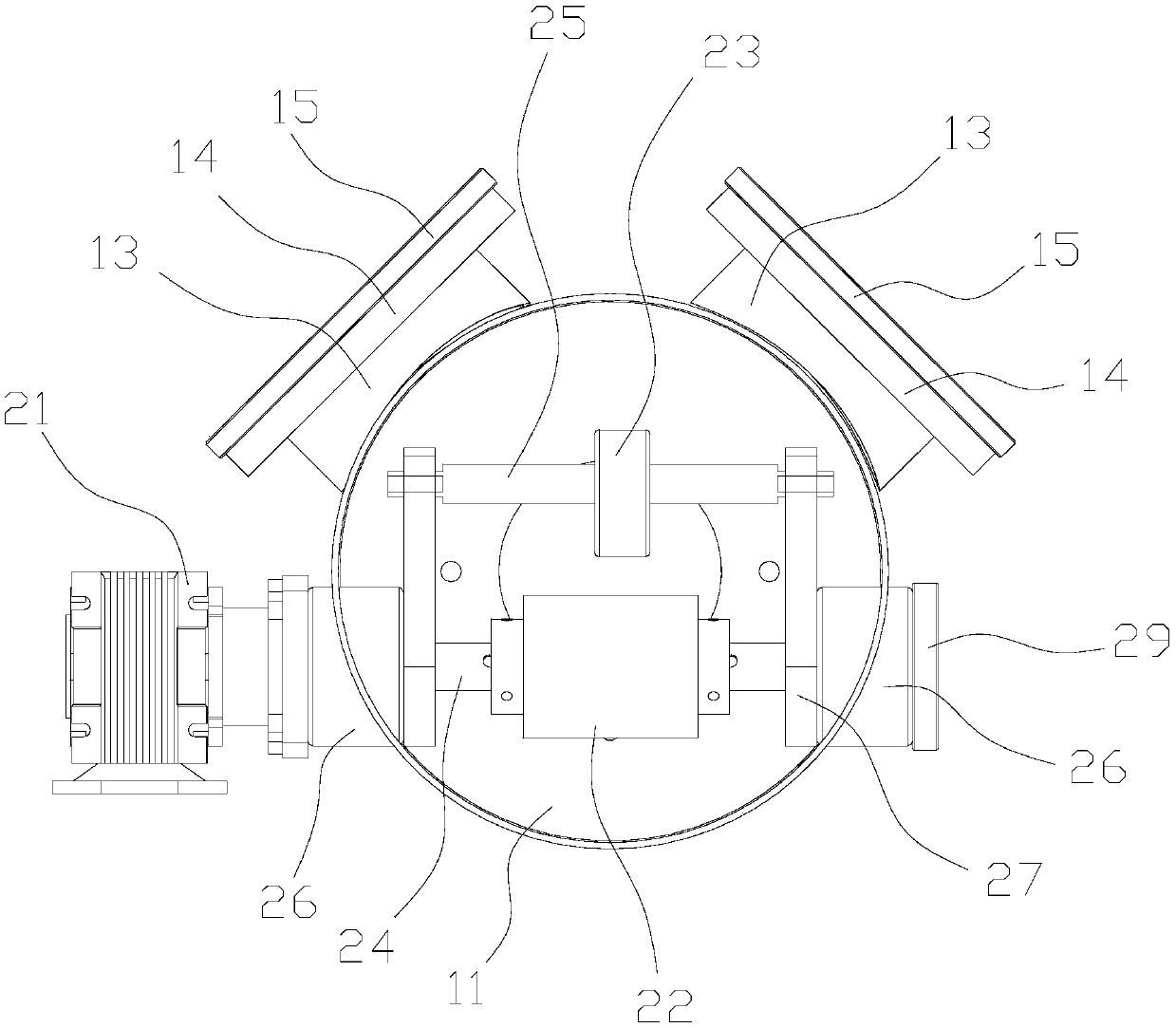

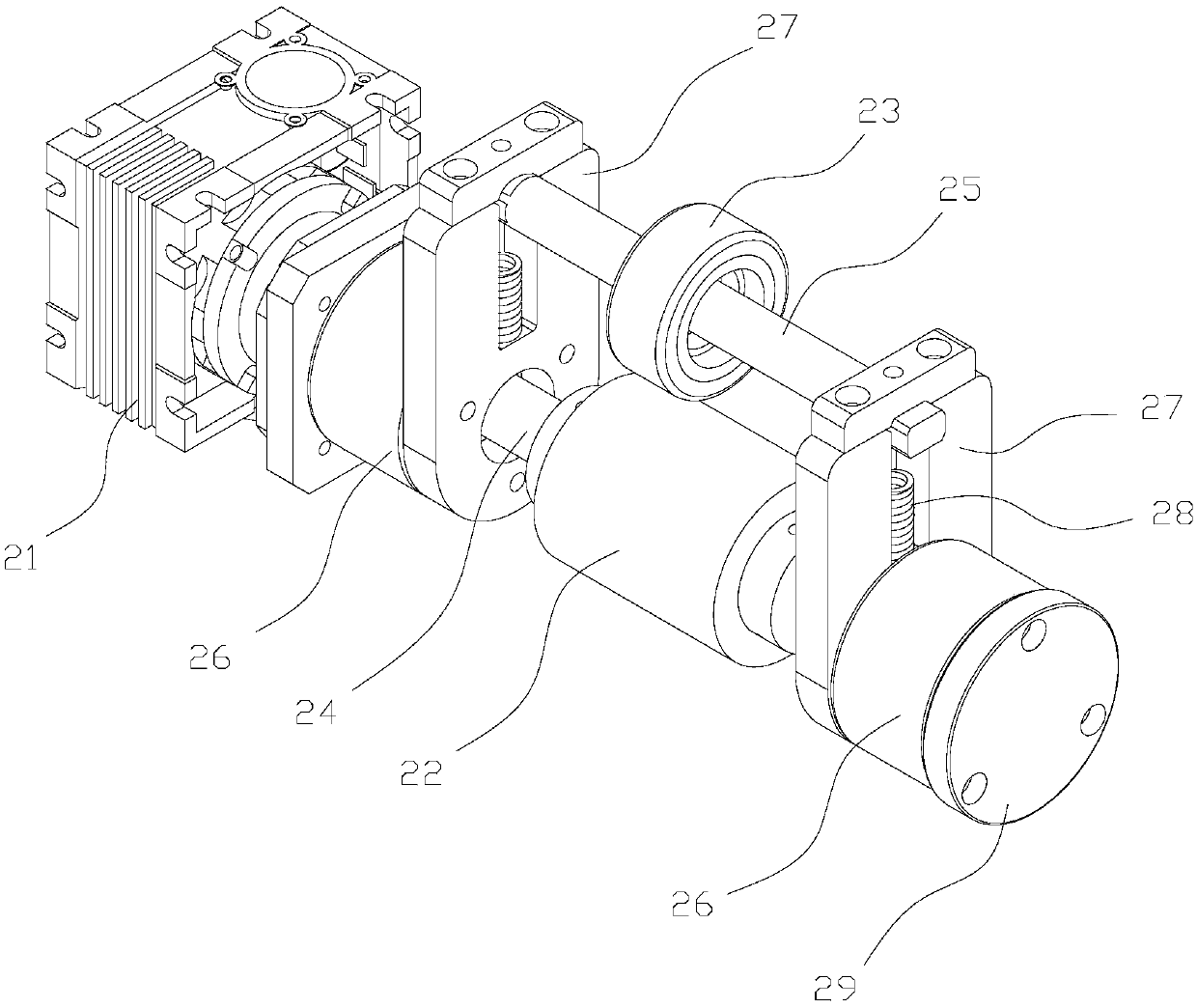

[0022] refer to Figure 1 to Figure 3 , the present invention provides a fully-enclosed traction mechanism in the tube, which is used for the transmission and traction of heat-shrinkable tubes, including an internal traction tube 1 and a traction device 2; the internal traction tube 1 is a cylindrical tube facing forward and backward, and the traction device 2 includes a worm gear reducer 21, a driving wheel 22, a driven wheel 23, a driving shaft 24, a final shaft 25, two bearing sleeves 26 installed at the left and right ends of the driving shaft 24, and two final shafts for supporting and installing the final shaft 25 Mounting plate 27; the traction device 2 is relatively fixedly installed with the inner traction tube 1 in such a way that the two bearing sleeves 26 pass through the inner traction tube 1 tube wall and are supported by the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com