Self-elevating production platform capable of moving freely

A production platform, self-elevating technology, applied in ship construction, anchoring arrangements, ships, etc., can solve the problems of high risk and high towing cost, and achieve the effect of rapid release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

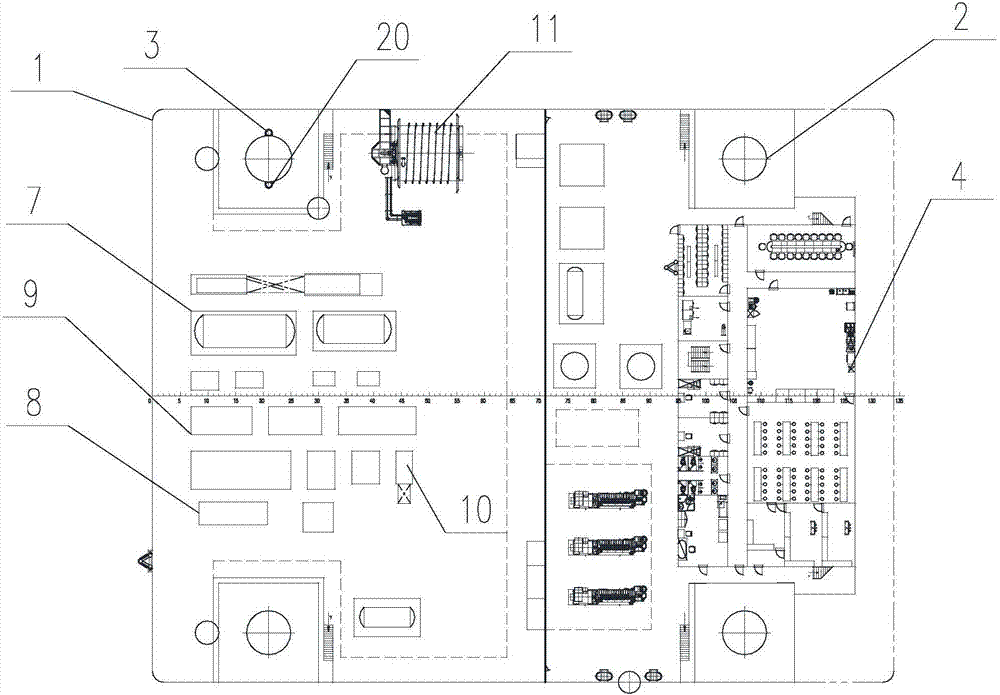

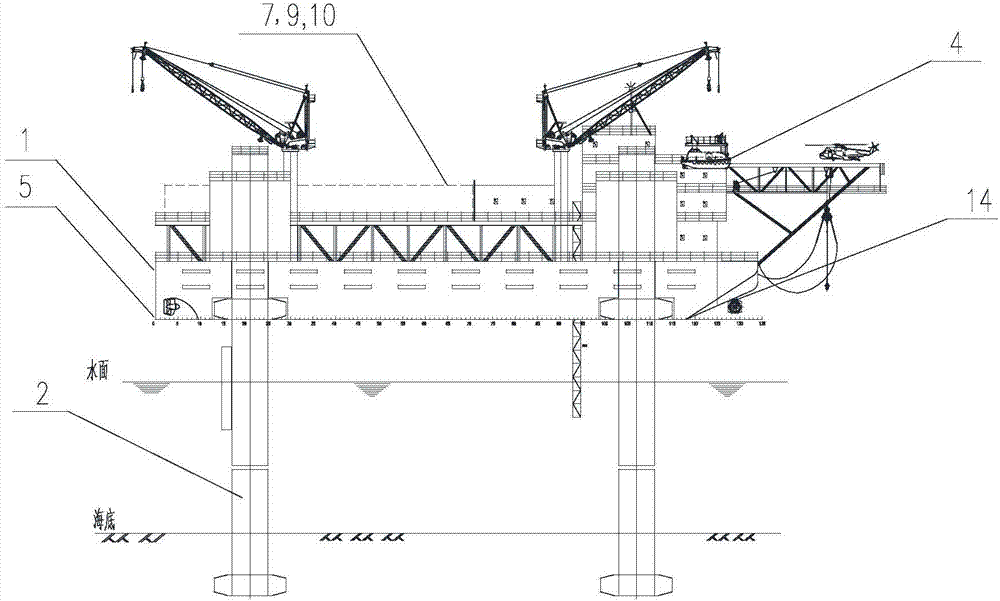

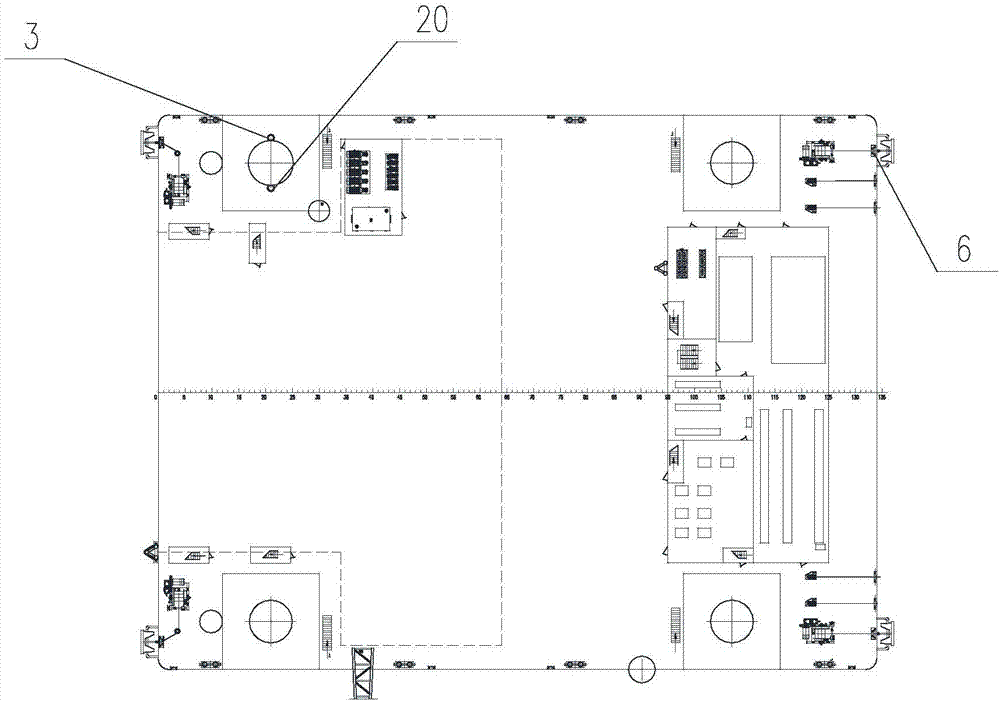

[0016] see Figure 1 to Figure 4 , a self-elevating production platform that can move freely, including a platform main body 1, pile legs 2 and its lifting system, and a crude oil processing system 7 connected to an underwater production system and an underwater control module are arranged on the platform main body 1 8. Production water treatment system 9, fuel gas treatment system 10, export equipment 11, mooring system 6, living building 4, helicopter deck, liquid tank and mechanical cabin. The living building 4 is arranged at the bow of the platform, and the helicopter deck is arranged in front of the upper floor of the living building 4 to provide traffic conditions for the platform personnel. Mooring systems are provided at the stern an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com